In-situ inorganic-organic composite spinning diaphragm as well as preparation method and application thereof

A composite spinning and membrane technology, which is applied in the field of in-situ inorganic-organic composite spinning membrane and its preparation, can solve the problems of difficult to achieve orderly regulation of ions and improvement of electrochemical performance, and achieve long-term storage performance and ionic conductivity. Effect of high and excellent physical properties and electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

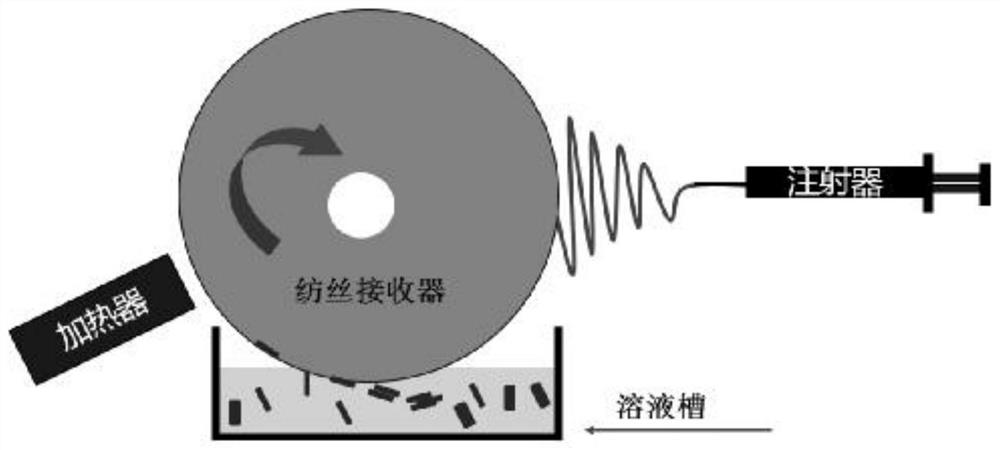

[0041] see figure 1 , is a schematic diagram of the preparation process of the in-situ inorganic-organic composite spinning membrane of the present invention. The preparation method of the in-situ organic-inorganic composite spinning diaphragm of the present invention comprises the following steps:

[0042] Step S1, using an electrospinning process to fabricate a spinning diaphragm on the surface of the spinning receiver;

[0043] Specifically, the electrospinning process includes the following steps:

[0044] A certain amount of polymer material is dissolved in an organic solvent as a spinning solute, heated and stirred to form a translucent spinning solution without air bubbles, and the mass fraction of the spinning solution is 5-30wt%; wherein, the organic solvent is selected from N , one or more of N-dimethylformamide, N, N-dimethylacetamide, dimethyl sulfoxide, sulfolane; the polymer material is selected from polyvinylidene fluoride, polyacrylonitrile, polyylidene One ...

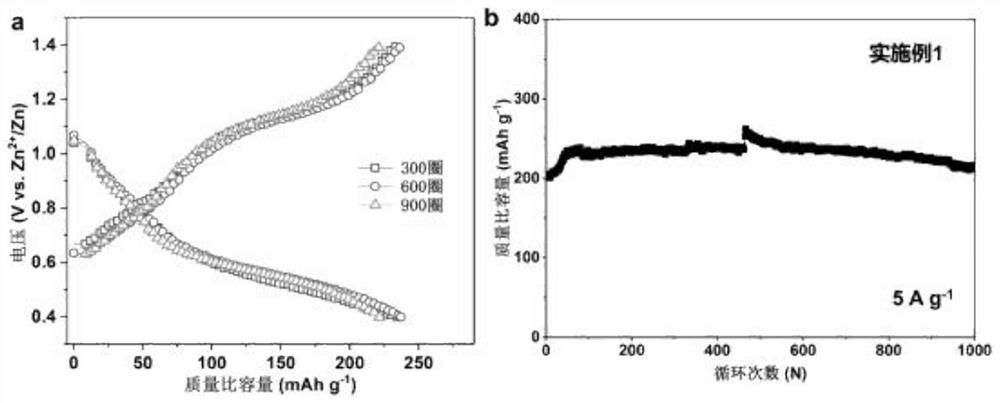

Embodiment 1

[0056] Dissolving the polyacrylonitrile powder in the DMF solvent as the solute of the spinning solution to prepare a 20 wt% PAN polymer spinning solution until the solution is uniform and transparent to obtain a pure PAN spinning solution;

[0057] Adjust the negative high voltage of the electrospinning machine to -2.3kV, the positive high voltage to 9.8kV, and the injection speed to 0.02mm min -1 , spinning receiver speed is 60mm·min -1 , making a spinning diaphragm on the surface of the spinning receiver;

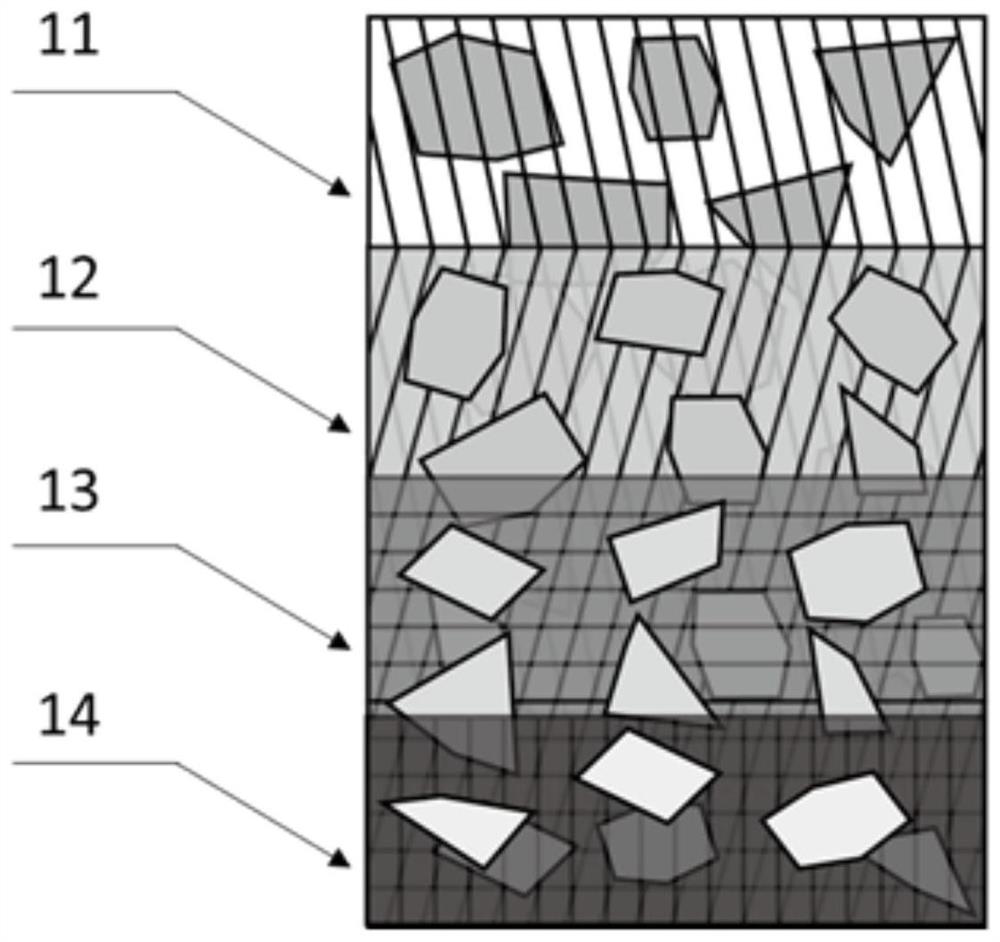

[0058] On the other side of the spinning receiver, a kaolin clay solution with a mass fraction of 5% is arranged, and the single-layer or nearly single-layer clay is attached to the spinning diaphragm in situ through the rotation of the rotating shaft, and then treated by a heater at 80°C. Continue the spinning diaphragm-inorganic clay attachment-drying cycle process to obtain a sandwich organic-inorganic composite spinning diaphragm;

[0059] The composite spinning me...

Embodiment 2

[0063] Polyvinylidene fluoride (PVDF) powder is prepared as a spinning solution solute to obtain a 5wt% polymer spinning solution; the PVDF solution is placed in a magnetic stirrer and stirred until the solution is uniform and translucent to obtain a spinning solution;

[0064] Adjust the electrospinning to adjust the negative high voltage to -1.3kV, the positive high voltage to 4.7kV, and the injection speed to 0.05mm min -1 , other parameters are identical with embodiment 1, and wherein clay material is montmorillonite;

[0065] After spinning, the composite spinning diaphragm was removed from the receiver and placed in a vacuum drying oven to dry. The prepared polyvinylidene fluoride-montmorillonite organic-inorganic composite spinning diaphragm had a thickness of 70 μm and a nanofiber diameter of 50-100nm.

[0066] Composite spinning diaphragm, zinc sheet, ammonium vanadate positive electrode sheet and 2mol / L zinc sulfate electrolyte were assembled into a button battery, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com