A single-component electroluminescent white light device and its preparation method

A white light device, single-component technology, applied in the direction of electric solid device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of limited development, spectral drift, complex preparation process, etc. The effect of process compatibility and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

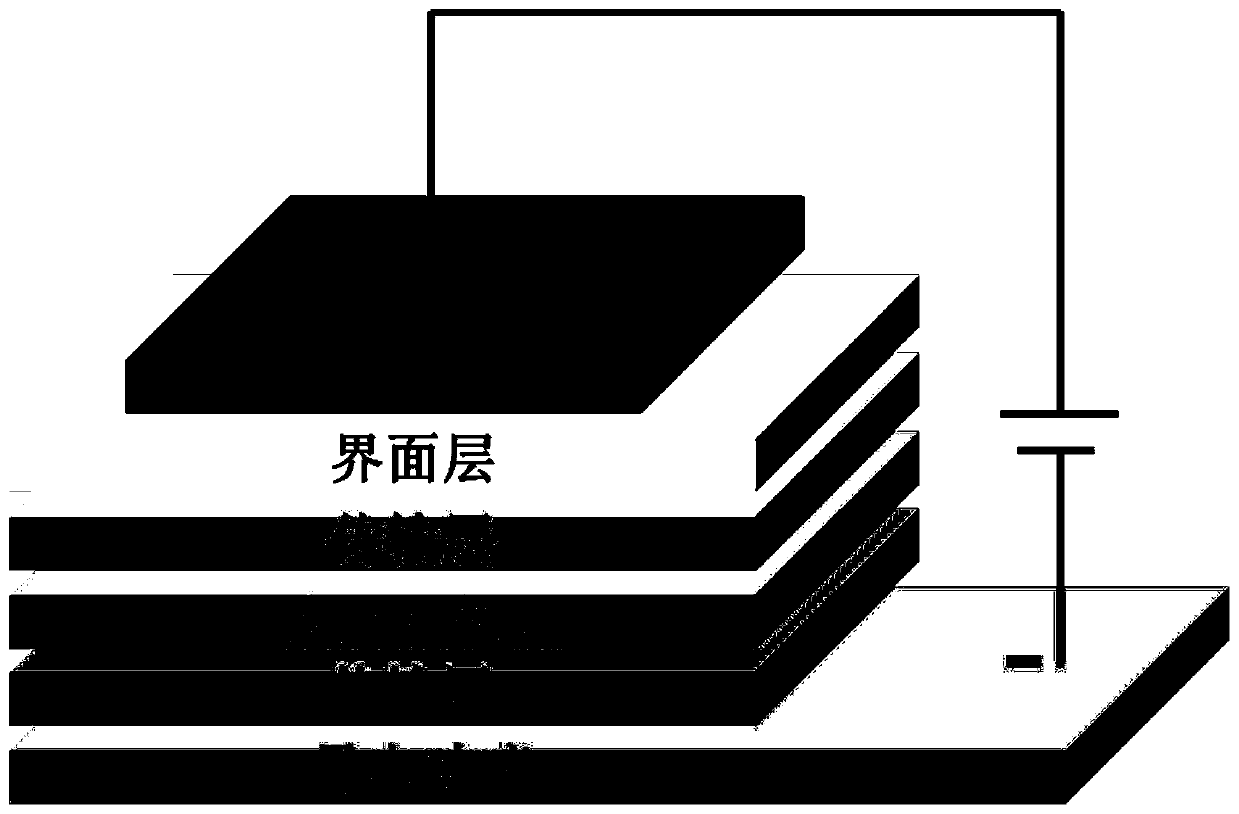

[0038] The method for preparing the above-mentioned electroluminescent device comprises the following steps:

[0039] 1) Using deionized water, acetone, isopropanol and ethanol successively as cleaning agents, cleaning the substrate under ultrasonic conditions, drying or drying after cleaning. sequentially depositing a first transport layer, a luminescent active layer and a second transport layer on the cleaned substrate;

[0040] 2) Transfer the substrate with the prepared second transport layer into the vacuum chamber, and pump the vacuum to 5╳10 -4 Below Pa, metal electrodes or composite electrodes are vapor-deposited on it; or liquid electrodes are directly applied, and the liquid electrodes are applied on the second transmission layer, and the electroluminescent device is obtained after completion.

[0041] Wherein, the preparation method of the luminescent active layer comprises the following steps:

[0042] (a) Place the thin film transfer of the prepared first transp...

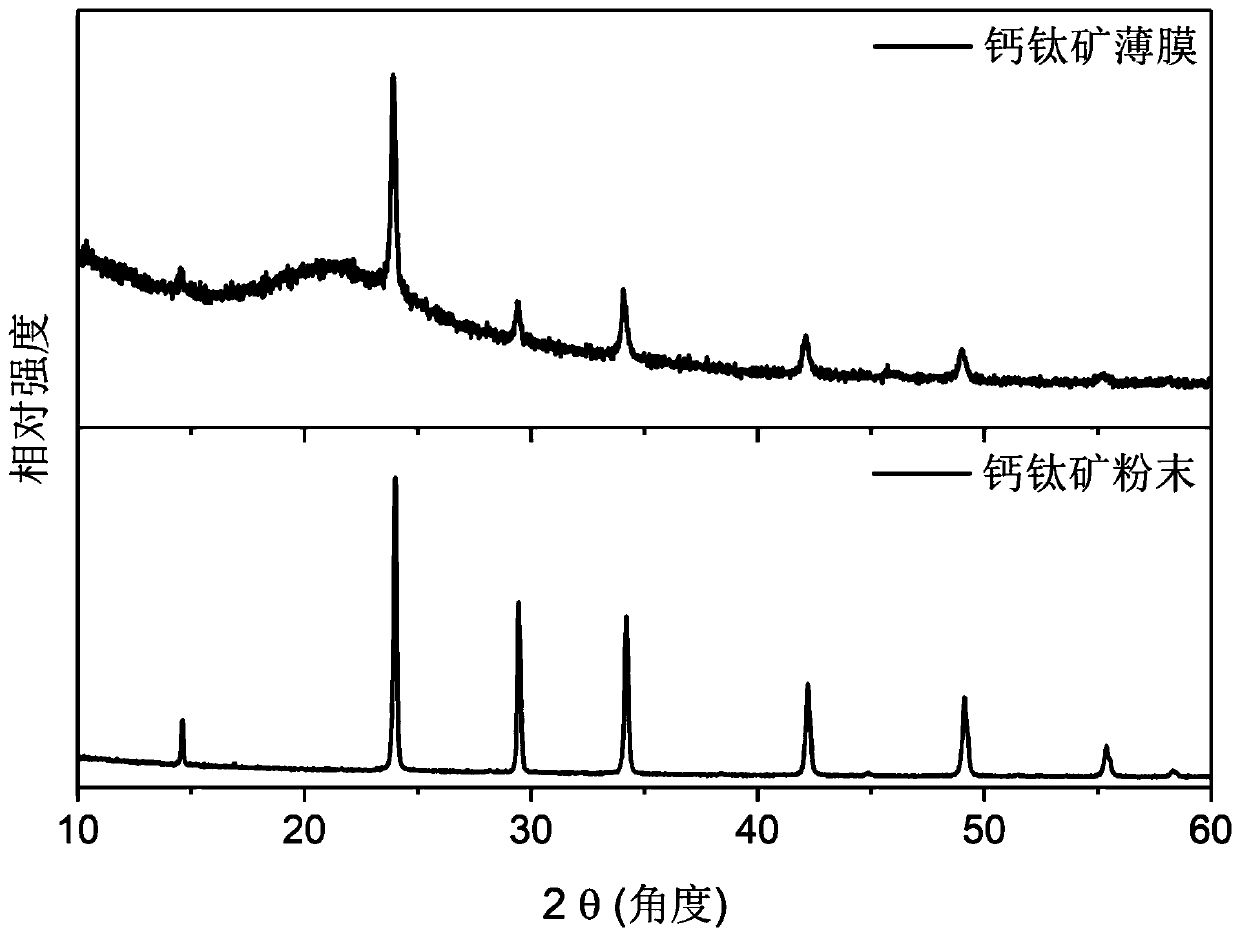

Embodiment 1

[0068] The preparation method of the electroluminescent white light device in this embodiment, its specific preparation steps are as follows:

[0069] a) Clean the 1.7cm by 1.7cm indium tin oxide (ITO) substrate with deionized water for 5 to 20 minutes, clean the indium tin oxide (ITO) substrate with acetone for 20 minutes, and clean the indium tin oxide (ITO) substrate with isopropanol for 20 minutes , wash the indium tin oxide (ITO) substrate with deionized water for 20 min, and then dry it with a nitrogen gun.

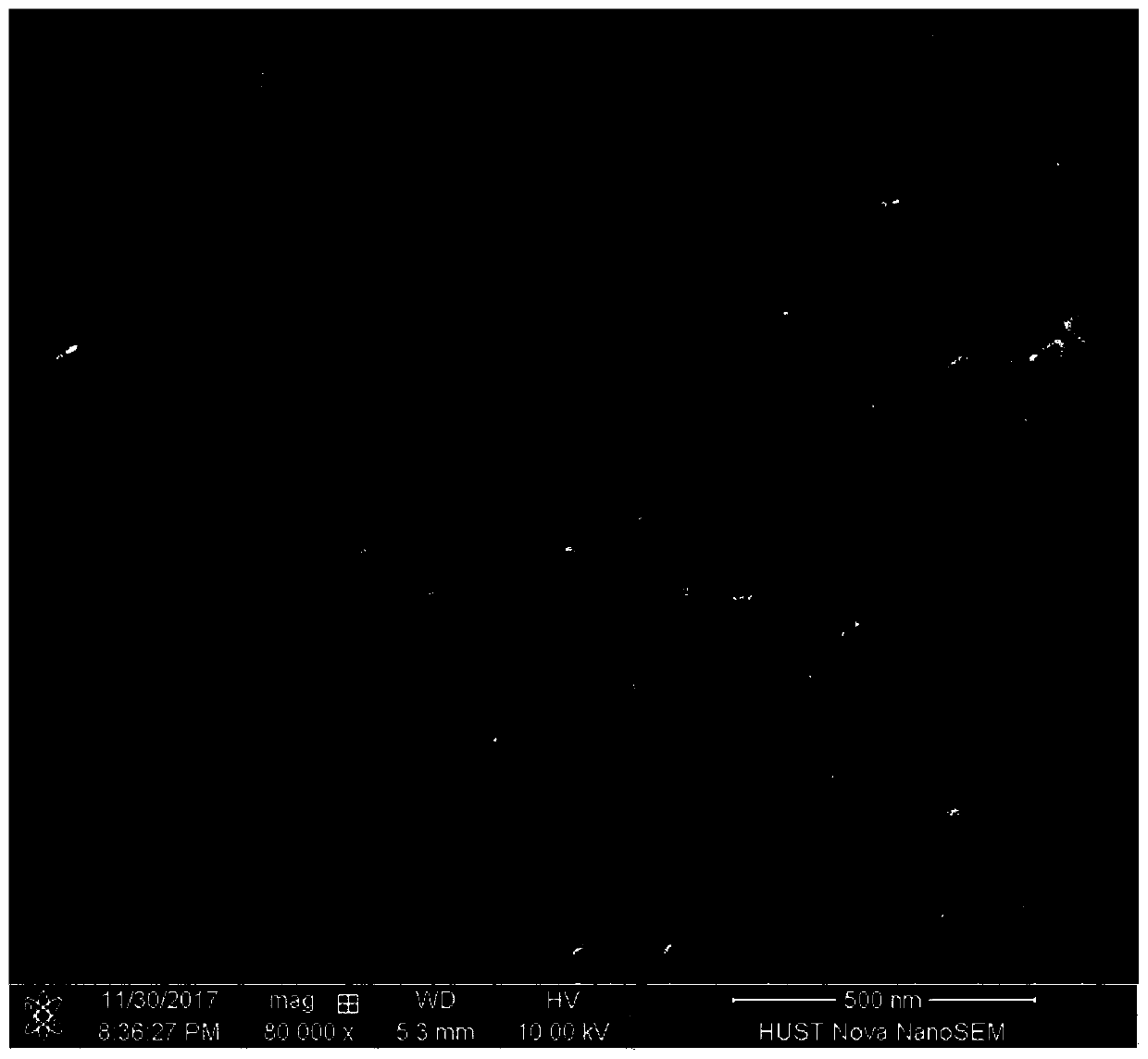

[0070] b) Spin-coating of zinc oxide (ZnO) nanoparticles for the first transport layer

[0071] (1) Dissolve 3mmol of zinc acetate dihydrate in 30ml of dimethyl sulfoxide (DMSO), 5.5mmol of tetramethylammonium hydroxide (TMAH) in 10ml of ethanol, and add dropwise to the above DMSO solution after completely dissolving , heated in a water bath at 30°C for 1h.

[0072] (2) Divide the solution (40ml in total) into four centrifuge tubes, each with 10ml. For the first ...

Embodiment 2

[0090] The preparation method of the electroluminescent white light device in this embodiment, its specific preparation steps are as follows:

[0091] a) Wash the 1.7cm by 1.7cm indium tin oxide (ITO) substrate with deionized water for 20 minutes, clean the indium tin oxide (ITO) substrate with acetone for 20 minutes, clean the indium tin oxide (ITO) substrate with isopropanol for 20 minutes, and use The indium tin oxide (ITO) substrate was cleaned with deionized water for 20 minutes, and then dried with a nitrogen gun.

[0092] b) Spin-coating of zinc oxide (ZnO) nanoparticles for the first transport layer

[0093] (1) Dissolve 3mmol of zinc acetate dihydrate in 30ml of dimethyl sulfoxide (DMSO), 5.5mmol of tetramethylammonium hydroxide (TMAH) in 10ml of ethanol, and add dropwise to the above DMSO solution after completely dissolving , heated in a water bath at 30°C for 1h.

[0094] (2) Divide the solution (40ml in total) into four centrifuge tubes, each with 10ml. For the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com