Iron-based biochar sponge composite material as well as preparation method and application thereof

A composite material and biochar technology, applied in chemical instruments and methods, water pollutants, and other chemical processes, to achieve high adsorption efficiency, good impact resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Dry and grind 16 different biomass raw materials, pass through a 100-mesh sieve, take 10.00g of biomass raw materials and put them into a tube furnace, continuously feed nitrogen, the pyrolysis temperature is 600°C, the heating time is 2h, and the holding time is 2h. After cooling, the original biochar is obtained.

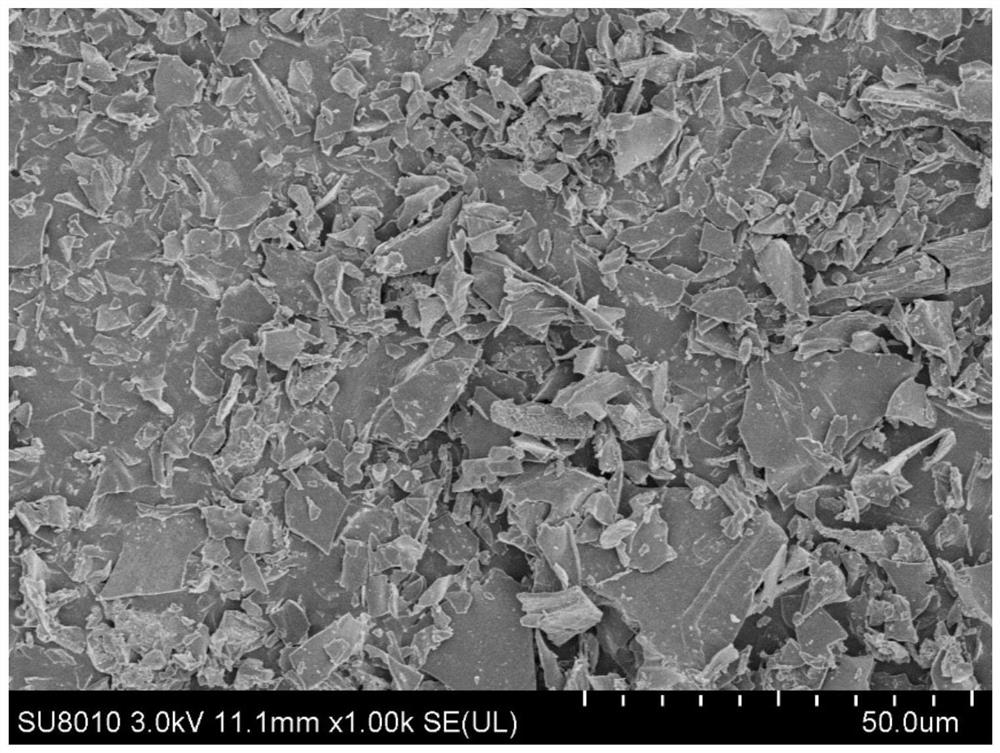

[0043]2. Determination of basic physical and chemical properties of 16 kinds of raw biochar, including elemental analysis, pH, ash content, yield, specific surface area, total porosity, pore size, scanning electron microscope, etc. The results are shown in Table 1 and Table 2, and the scanning electron microscope image of coconut shell silk biochar is as follows: figure 1 shown.

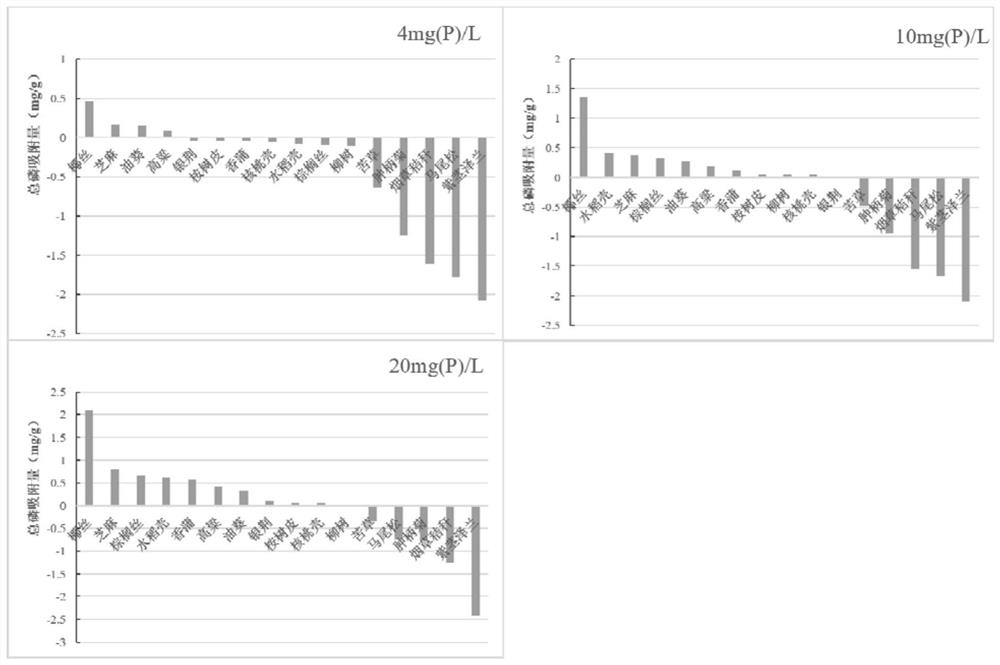

[0044] 3. Add 16 kinds of biochars to the wastewater solution with phosphate ion concentration gradients of 5mg / L, 10mg / L and 20mg / L respectively. Then put it into a shaker to oscillate, adjust the initial pH of the solution to be 7, the adsorption temperature is 25°C, the o...

Embodiment 2

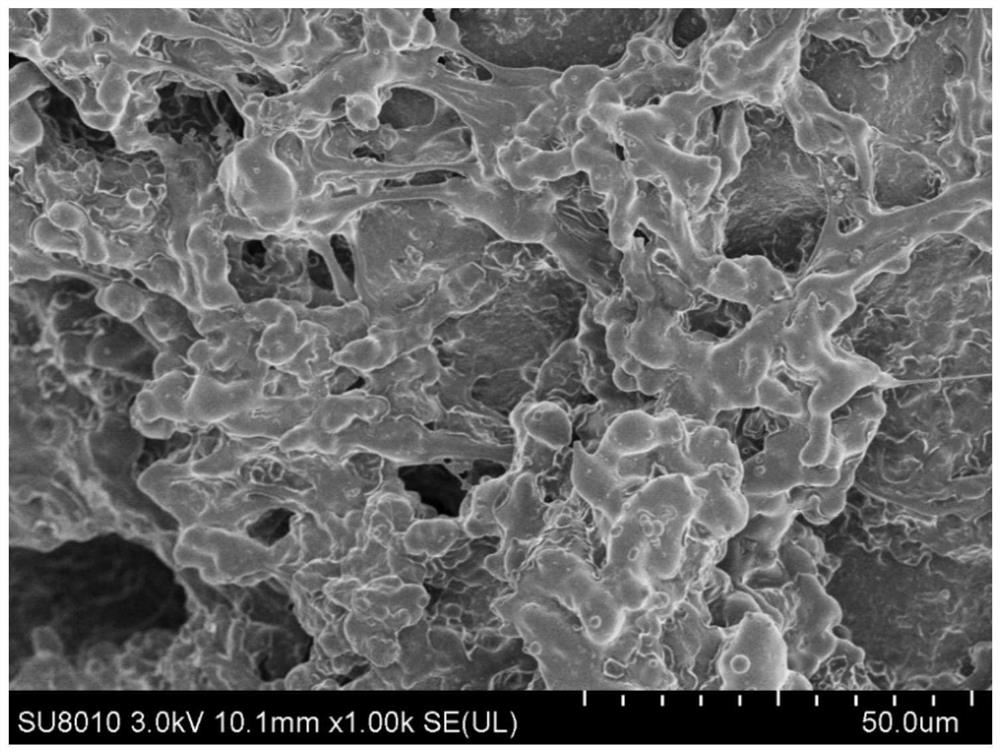

[0056] Preparation of S1 biochar: Crumble coconut shell silk biomass raw materials into small pieces and put them into a tube furnace, continuously feed nitrogen, set the pyrolysis temperature to 600°C, heat up for 2 hours, and hold for 2 hours. Then cool and pass through a 100-mesh sieve to obtain raw biochar.

[0057] S2 modification treatment: fix the volume of ferric chloride hexahydrate to 1mol / L, add the original biochar prepared by S1 into 1mol / L ferric chloride solution and stir at a stirring speed of 180rpm for 12h. After impregnation, filter, put the solid in an oven and dry at 65°C for 12 hours, then put the modified biochar in a tube furnace with nitrogen atmosphere and pyrolyze it at 200°C for 30 minutes, take it out after cooling, and get the iron-based biochar carbon.

[0058] S3 in-situ polymerization: polyvinyl alcohol (1799), that is, the degree of polymerization is 1700, the degree of alcoholysis is 99%, the addition amount is 10g; the mass percentage of fo...

Embodiment 3

[0067] The iron-based biochar-sponge composite material prepared in Example 2 was added to wastewater solutions with phosphate ion concentration gradients of 5 mg / L, 10 mg / L and 20 mg / L, respectively. Then put it into a shaker to shake, adjust the initial pH of the solution to 7, the adsorption temperature to 25° C., the shaking speed to 180 rpm, and the shaking time to 12 hours. In addition, the original coconut shell silk biochar and iron-based modified coconut shell silk biochar were used as controls, and the adsorption experiment of phosphate ions was carried out according to the above method. The comparison results of phosphorus adsorption capacity of different adsorbents are as follows: Figure 4 shown.

[0068] Generally speaking, the phosphorus adsorption capacity of iron-based biochar PVF materials is better than that of iron-based biochar and original biochar. Therefore, by loading iron-based biochar materials on PVF, we have solved the problem to a certain extent. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com