Low-temperature self-cross-linking waterborne epoxy modified acrylic resin, preparation method and application thereof

An acrylic resin, water-based epoxy technology, applied in applications, home appliances, inks, etc., can solve the problems of poor resin stability, difficult to control, and high temperature of ring-opening reaction, and achieve strong adhesion, improved adhesion, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

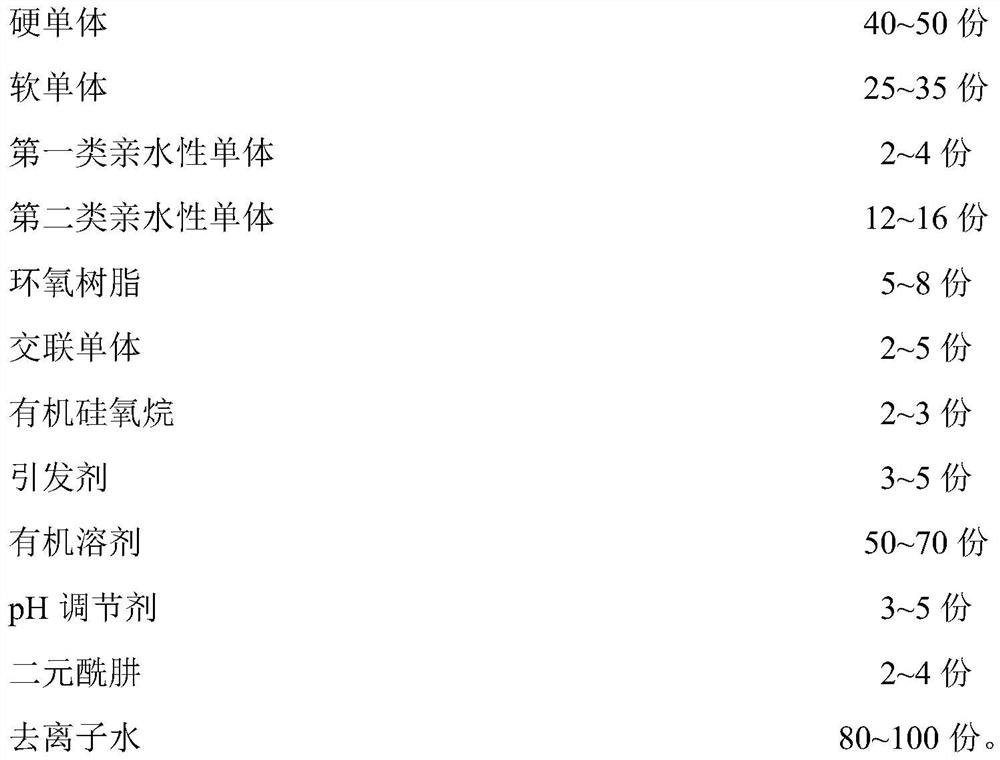

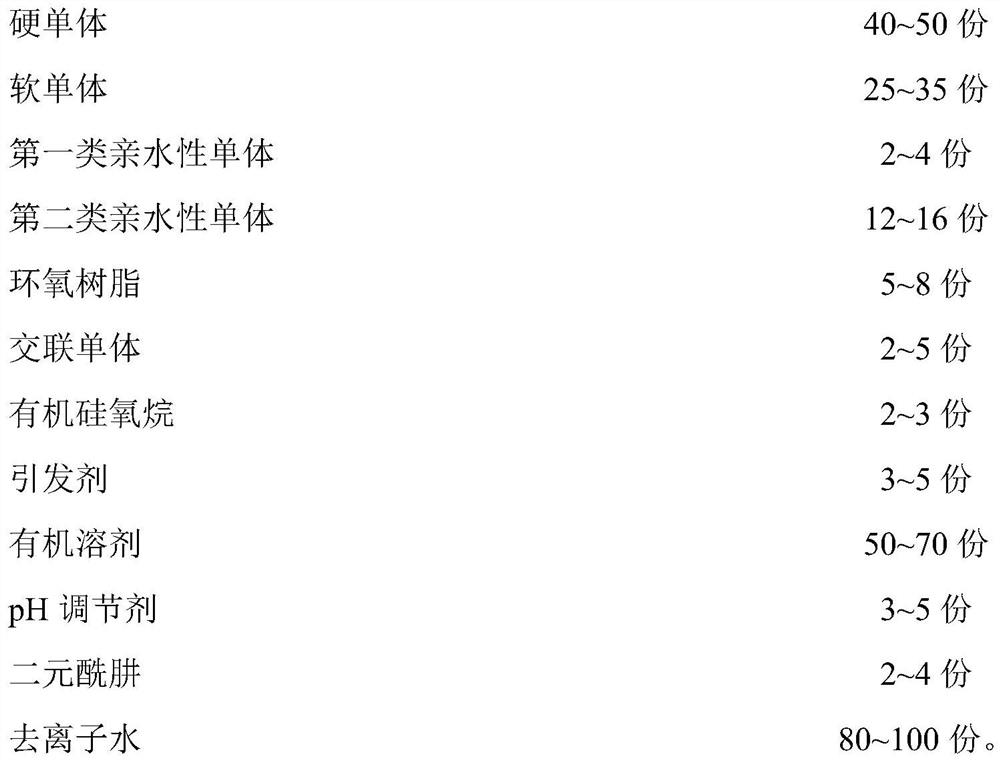

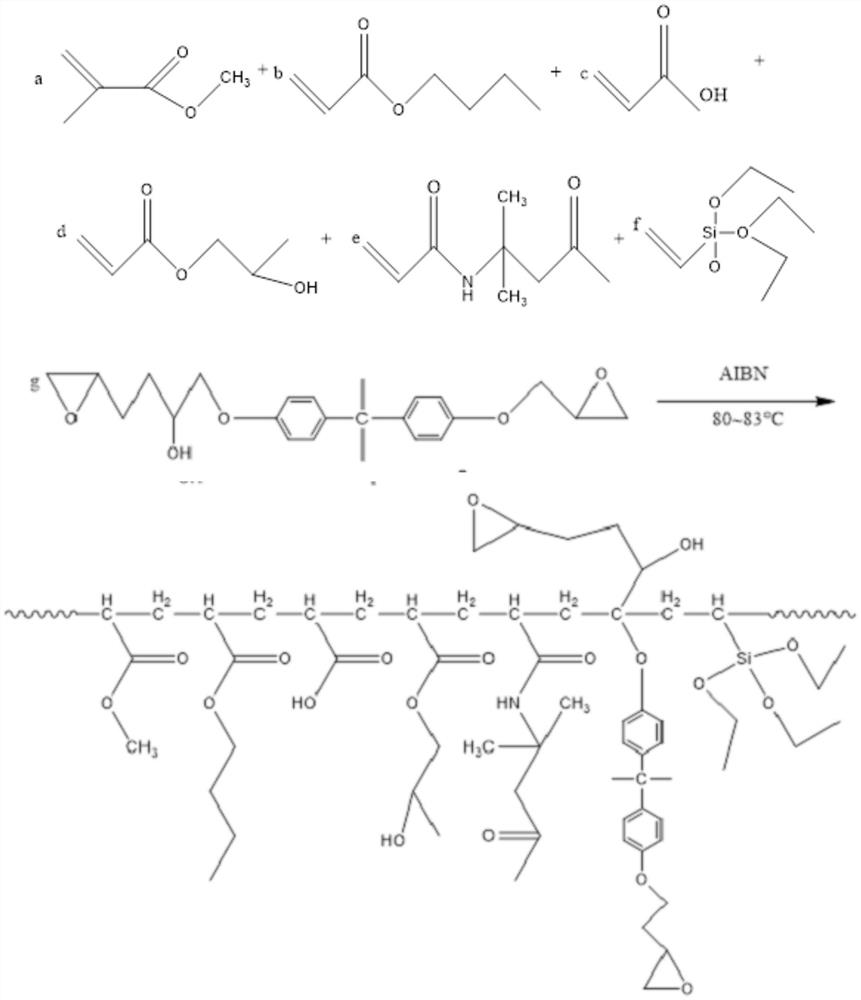

[0068] 1) Preparation of water-based low-odor, low-temperature self-crosslinking modified acrylic resin

[0069] Take 0.6g of azobisisobutyronitrile and 60g of absolute ethanol, fully dissolve them, put them into a reaction kettle with a reflux condenser, and keep reflux at 78°C for 30min; mix 40g of methyl methacrylate, 35g of butyl acrylate ester, 3g acrylic acid, 15g hydroxypropyl acrylate, 5g E-51 epoxy resin, 2g vinyltriethoxysilane, 3g diacetone acrylamide, 2.4g azobisisobutyronitrile, mix and then use The peristaltic pump completed the dropwise addition for 3 hours, and controlled the reaction temperature to 82°C. After the dropwise addition was completed, keep the temperature for 3h; after the heat preservation, lower the temperature of the reactor to 45°C, and add 3g of ammonia water and 0.4g of dimethylethanolamine for neutralization for 15min; Then add 90g of deionized water and 2.4g of adipic acid dihydrazide, stir for 15-20min, filter and discharge. A low-tempera...

Embodiment 2

[0073] 1) Preparation of water-based low-odor, low-temperature self-crosslinking modified acrylic resin

[0074]Take 0.8g of azobisisoheptanonitrile, 60g of absolute ethanol, and 10g of isopropanol after fully dissolving them, add them into a reaction kettle with a reflux condenser, and keep reflux at 78°C for 30min; add 45g of ethyl methacrylate, 30g of butyl acrylate, 2.5g of acrylic acid, 0.5g of itaconic acid, 16g of hydroxypropyl acrylate, 5g of E-51 epoxy resin, 1.5g of γ-(methacryloxy)propyltrimethoxysilane, 3.5g N-methylolacrylamide and 3.2g of azobisisoheptanonitrile were mixed, and then added dropwise with a peristaltic pump for 3 hours, and the reaction temperature was controlled at 82°C. After the addition was completed, keep warm for 3 hours; , lower the temperature of the reactor to 45°C, add 2.5g of ammonia water and 0.3g of dimethylethanolamine to neutralize for 15min; then add 90g of deionized water and 2.8g of oxalic acid dihydrazide, stir for 15-20min, filte...

Embodiment 3

[0078] 1) Preparation of water-based low-odor, low-temperature self-crosslinking modified acrylic resin

[0079] Take 0.5g of benzoyl peroxide, 75g of absolute ethanol and 5g of isopropanol, fully dissolve them, put them into a reaction kettle with a reflux condenser, keep reflux at 80°C for 30min; add 50g of isobutyl methacrylic acid ester, 25g methyl acrylate, 3g methacrylic acid, 16g hydroxypropyl methacrylate, 8g E-12 epoxy resin, 3g vinyltriethoxysilane, 2g N-hydroxyethylacrylamide, 2g Azobisisobutyronitrile was mixed, then added dropwise with a peristaltic pump for 2.5 hours, and the reaction temperature was controlled at 82°C. After the dropwise addition was completed, it was kept for 3 hours; after the heat preservation was completed, the temperature of the reactor was lowered to 45°C, and 3g of ammonia water and 0.4g of triethylamine were neutralized for 15 minutes; then 85g of deionized water and 2.4g of succinic acid dihydrazide were added, stirred for 15-20 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com