Ruthenium-containing hard alloy material and preparation process thereof

A cemented carbide and preparation technology, applied in the field of cemented carbide, can solve problems such as insufficient toughness and decreased surface corrosion resistance, and achieve the effects of excellent electrical corrosion resistance, good toughness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A ruthenium-containing cemented carbide material and a preparation process thereof, comprising:

[0028] For providing the ruthenium salt solution of ruthenium metal;

[0029] The cobalt salt solution used to provide cobalt metal reacts with the ruthenium salt solution to obtain co-precipitation of cobalt oxalate; the ruthenium salt solution includes ruthenium acetate solution; the cobalt salt solution includes cobalt stearate solution, etc.;

[0030] The tungsten carbide powder used to enhance the hardness of the alloy, the FSSS particle size of the tungsten carbide powder is 2 μm, and the particle size of the chromium powder is 1.0 μm.

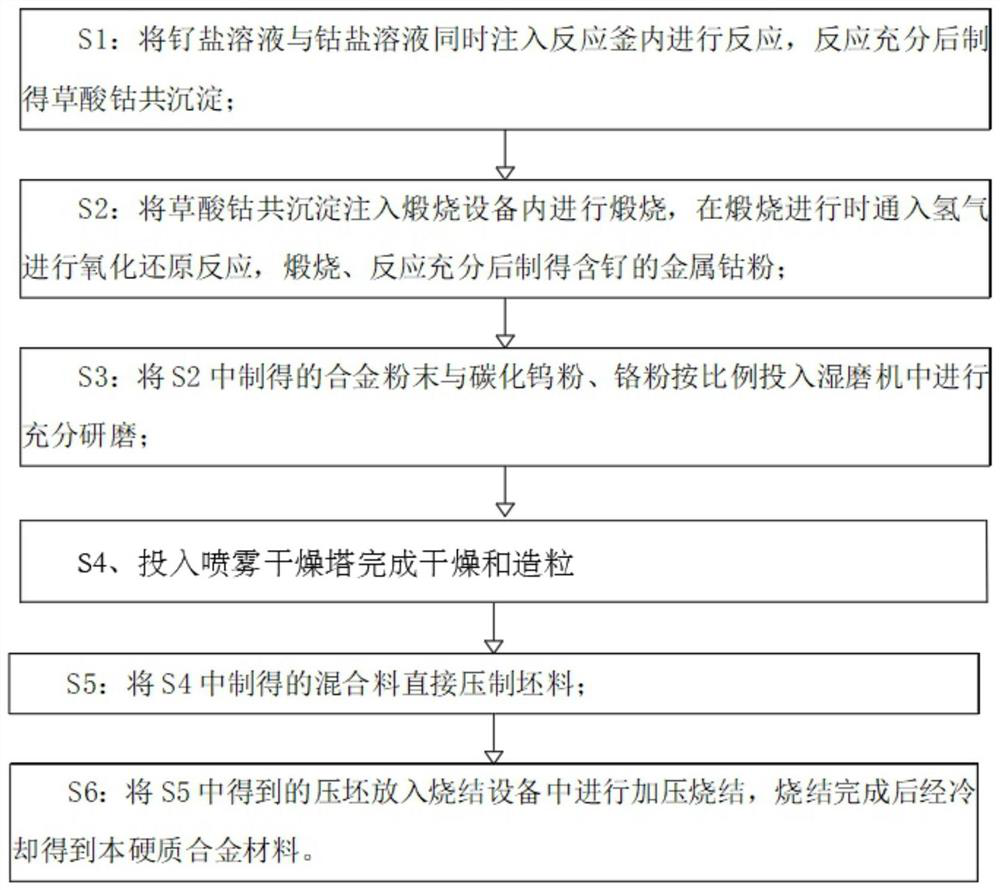

[0031] The present invention also provides a preparation process for a ruthenium-containing cemented carbide material, comprising the following steps:

[0032] S1: inject the ruthenium salt solution and the cobalt salt solution into the reaction kettle at the same time to react, and after the reaction is sufficient, co-precipitation ...

Embodiment 2

[0046] A ruthenium-containing cemented carbide material and a preparation process thereof, comprising:

[0047] For providing the ruthenium salt solution of ruthenium metal;

[0048] The cobalt salt solution used to provide cobalt metal reacts with the ruthenium salt solution to obtain co-precipitation of cobalt oxalate; the ruthenium salt solution includes ruthenium iodide solution; the cobalt salt solution includes cobalt neodecanoate solution;

[0049] Tungsten carbide powder and chromium powder are used to enhance the hardness of the alloy. The FSSS particle size of the tungsten carbide powder is 3 μm, and the particle size of the chromium powder is 1.5 μm.

[0050] The present invention also provides a preparation process for a ruthenium-containing cemented carbide material, comprising the following steps:

[0051] S1: inject the ruthenium salt solution and the cobalt salt solution into the reaction kettle at the same time to react, and after the reaction is sufficient, ...

Embodiment 3

[0065] A ruthenium-containing cemented carbide material and a preparation process thereof, comprising:

[0066] For providing the ruthenium salt solution of ruthenium metal;

[0067] The cobalt salt solution used to provide cobalt metal reacts with the ruthenium salt solution to obtain co-precipitation of cobalt oxalate; the ruthenium salt solution includes ruthenium trichloride solution; the cobalt salt solution includes cobalt naphthenate solution;

[0068] Tungsten carbide powder and chromium powder are used to enhance the hardness of the alloy. The FSSS particle size of the tungsten carbide powder is 5 μm, and the particle size of the chromium powder is 2.0 μm.

[0069] The present invention also provides a preparation process for a ruthenium-containing cemented carbide material, comprising the following steps:

[0070] S1: inject the ruthenium salt solution and the cobalt salt solution into the reaction kettle at the same time to react, and after the reaction is sufficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com