Low-temperature curing high-solid epoxy coating and preparation method thereof

A high-solid, epoxy-based technology, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of affecting the anti-corrosion performance of coatings, slow film-forming reaction, etc., and achieve excellent hardness and salt spray resistance. Excellent mechanical properties and the effect of increasing crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0024] Prepare silane-modified epoxy resin according to the following formula:

[0025] E51 epoxy resin: 30, E20 epoxy resin: 30, xylene: 9, butanol: 4, absolute ethanol: 5, 3-(2,3-epoxypropoxy)propyltrimethoxysilane: 5 , 3-isocyanatopropyltrimethoxysilane: 20, dibutyltin dilaurate: 1.

[0026] Silane-modified epoxy resin is prepared by the following method:

[0027] Add E51 epoxy resin, E20 epoxy resin, xylene, and butanol into the reaction tank, stir evenly, add 3-isocyanatopropyltrimethoxysilane, dibutyltin dilaurate, heat up to 80°C, and stir to react After 4 hours, the temperature was lowered to below 25°C, and 3-(2,3-glycidoxy)propyltrimethoxysilane and absolute ethanol were added and stirred evenly.

[0028] The above-mentioned silane-modified epoxy resin was used to prepare low-temperature curing high-solid epoxy coatings.

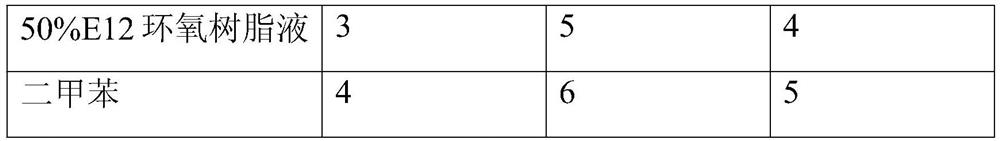

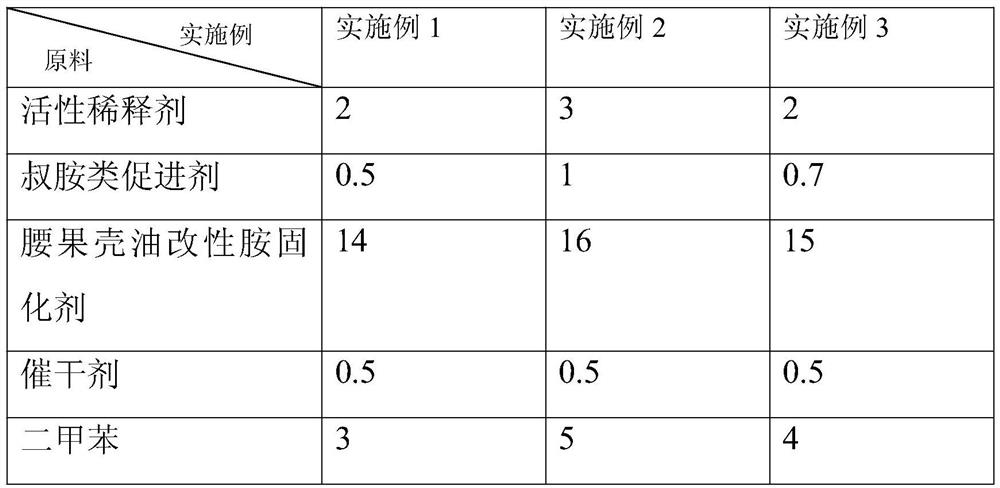

[0029] Embodiment 1-3 component A raw material parts by weight are shown in the following table:

[0030]

[0031]

[0032] Embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com