Nanocrystalline amorphous composite coating and preparation method thereof

A composite coating, nanocrystalline technology, applied in the direction of coating, nanotechnology, nanotechnology, etc., can solve the problems of thin coating, high friction coefficient, low bonding force of aluminum doped coating, etc., to achieve uniform distribution, The effect of excellent high temperature resistance, excellent strength and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

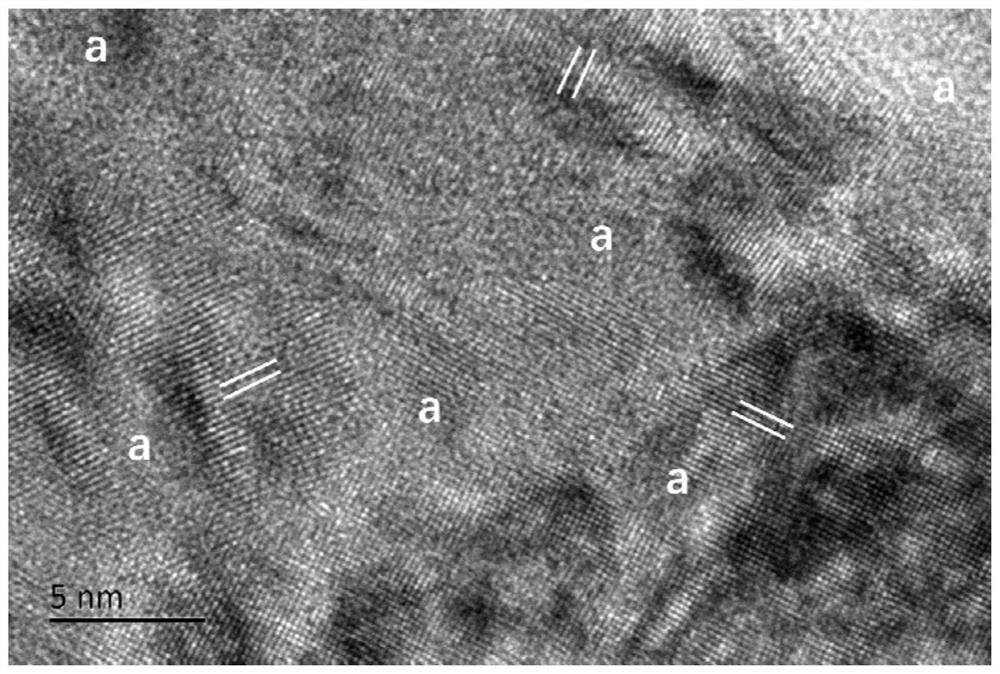

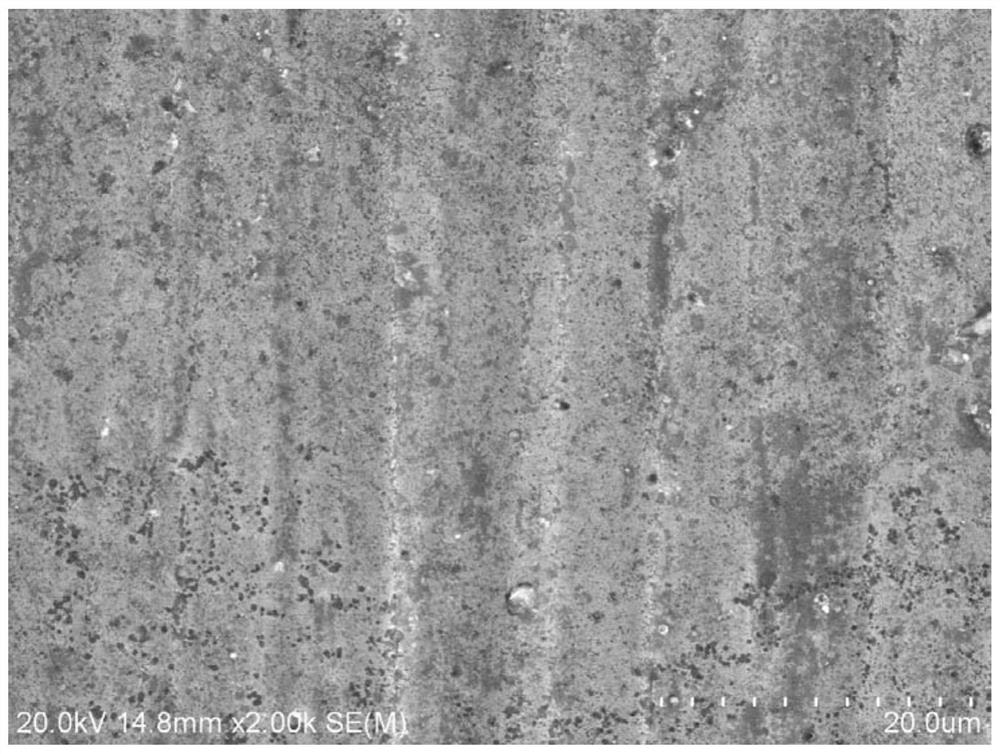

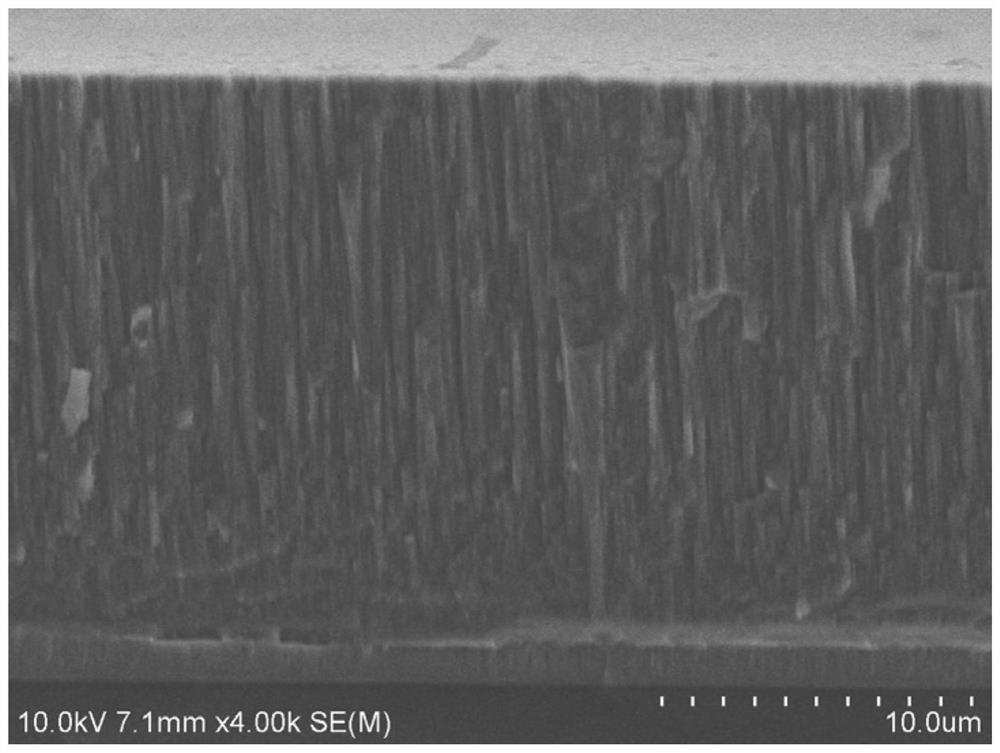

[0064] This embodiment is to deposit AlCrSiCN nanocrystalline amorphous composite coating on the surface of 304 stainless steel.

[0065] Stainless steel sheet pretreatment: Ultrasonic cleaning in acetone and alcohol for 10 minutes respectively.

[0066] Hang the stainless steel sheet on the tooling of the PEMS-3C plasma-enhanced magnetron sputtering coating system, close the vacuum chamber door, and evacuate. The coated targets are Cr targets and CrAl composite targets, both of which have a purity of 99.9 wt%.

[0067] Vacuum down to 1×10 -3 At Pa, the tooling rotation system is turned on at a speed of 3 revolutions per minute. Turn on the heating system, set the temperature to 400°C, until the temperature displayed by the thermocouple sensor in the vacuum chamber is 400°C, stabilize for 10 minutes, and keep the vacuum degree better than 1×10 -3 Pa.

[0068] 250 sccm of argon gas was introduced, the vacuum degree reached 1.0 Pa, the tungsten electrode was turned on, the f...

Embodiment 2

[0078] This embodiment is to deposit AlCrSiCN nanocrystalline amorphous composite coating on the surface of M2 high speed steel.

[0079] Pretreatment of high-speed steel sheet: Ultrasonic cleaning in acetone and alcohol for 10 minutes respectively.

[0080] Hang the M2 high-speed steel on the tooling of the PEMS-3C plasma-enhanced magnetron sputtering coating system, close the vacuum chamber door, and evacuate. The coated targets are Cr targets and CrAl composite targets, both of which have a purity of 99.9 wt%.

[0081] Vacuum down to 1×10 -3 At Pa, the tooling rotation system is turned on at a speed of 3 revolutions per minute. Turn on the heating system, set the temperature to 500°C, until the temperature displayed by the thermocouple sensor in the vacuum chamber is 500°C, stabilize for 10 minutes, and keep the vacuum degree better than 1×10 -3 Pa.

[0082] 300sccm of argon gas was introduced, the vacuum degree reached 2.0Pa, the tungsten wire electrode was turned on, ...

Embodiment 3

[0088] This embodiment is to deposit AlCrSiCN nanocrystalline amorphous composite coating on the surface of 304 stainless steel.

[0089] Stainless steel sheet pretreatment: Ultrasonic cleaning in acetone and alcohol for 15 minutes respectively.

[0090] Hang the stainless steel sheet on the tooling of the PEMS-3C plasma-enhanced magnetron sputtering coating system, close the vacuum chamber door, and evacuate. The coated targets are Cr targets and CrAl composite targets, both of which have a purity of 99.9 wt%.

[0091] Vacuum down to 1×10 -3 At Pa, the tooling rotation system is turned on at a speed of 3 revolutions per minute. Turn on the heating system, set the temperature to 300°C, until the temperature displayed by the thermocouple sensor in the vacuum chamber is 300°C, stabilize for 10 minutes, and keep the vacuum degree better than 1×10 -3 Pa.

[0092] 200 sccm of argon gas was introduced, the vacuum degree reached 0.8 Pa, the tungsten wire electrode was turned on, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com