Preparation method of silicon-carbene material and preparation method of electrode active material of silicon-carbene material

A silicon carbene and electrode technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of heavy metal pollution, low yield, spontaneous combustion, etc., and achieve the effects of not easy doping, high yield, and low preparation temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

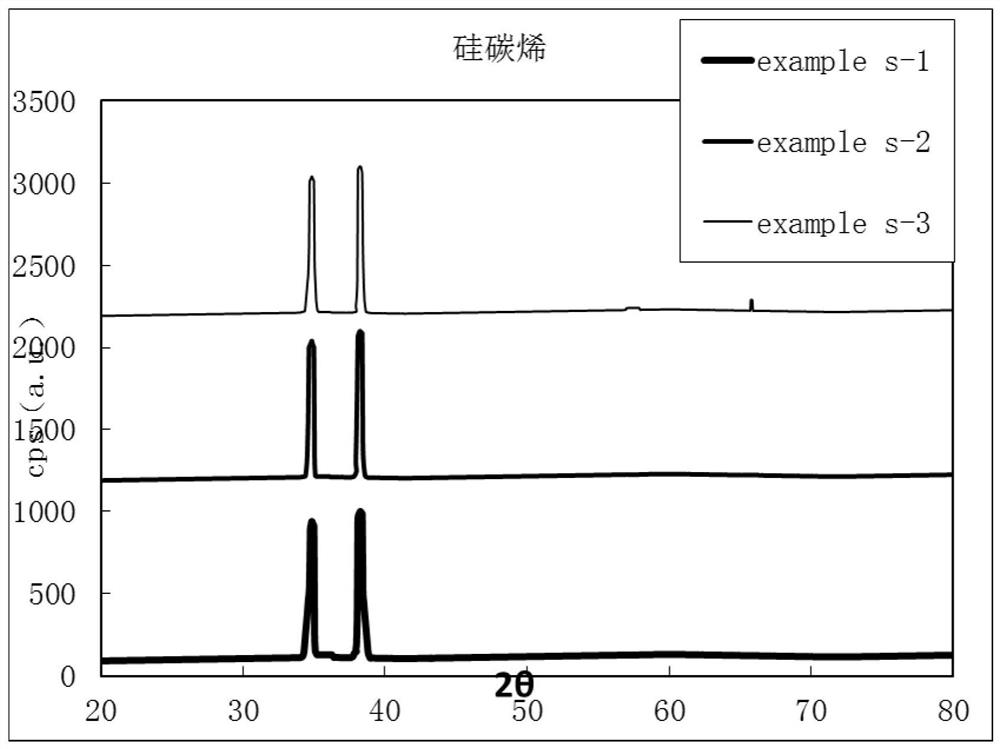

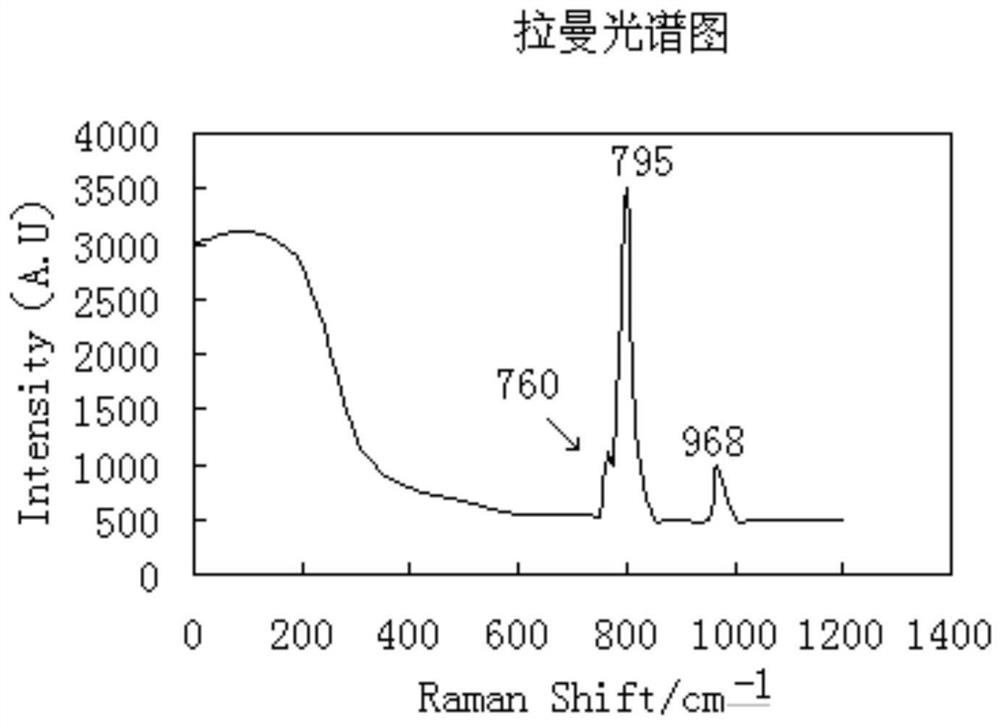

Examples

Embodiment 1

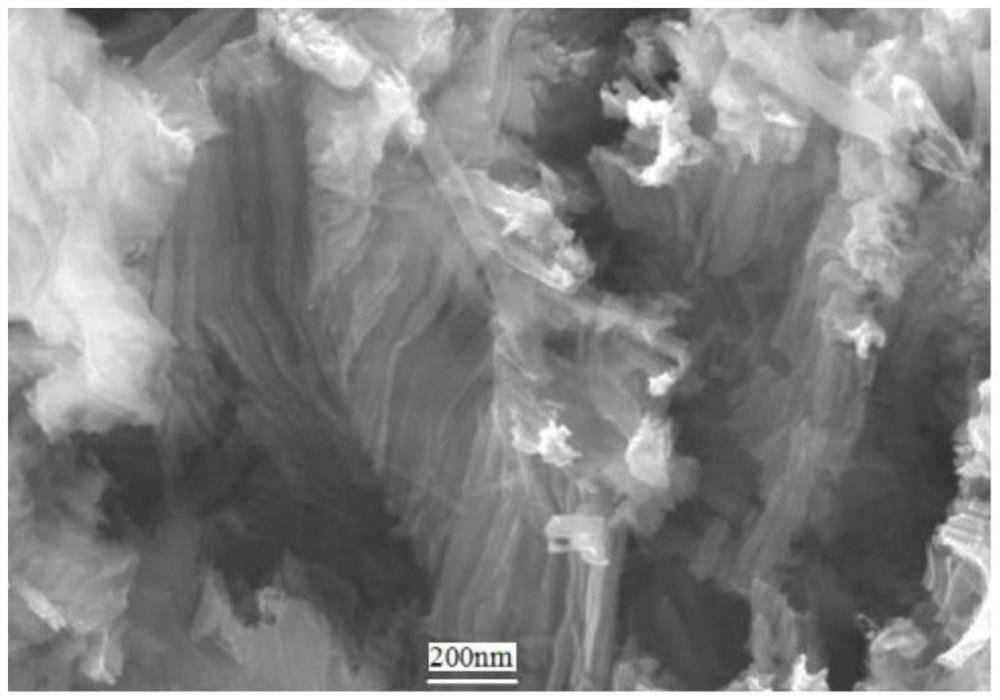

[0079] (1) Weigh 15g of pure graphite, mix it with metal gallium powder, pour it into the acetone solution in a vacuum stirrer and stir evenly, and seal and stir for 24 hours; Cake shape, pressed into the graphite boat, as a target, put the sample boat into the stainless steel shell reaction chamber, this reaction chamber has a reactant nozzle that produces high hydrogen dilute silane gas, located in the center of the reaction chamber directly above, here The chamber produces enhanced plasma, and the nozzle is 20cm away from the center of the bottom of the reaction chamber; at the top of the reaction chamber 10cm away from the center, there is a radio frequency magnetron sputtering gas nozzle with an angle θ=89~60 with the horizontal plane, and the electric field direction of the cathode and the anode Parallel, a strong electric field is formed between the sample base and the inert gas nozzle, and a voltage of 2000-20000V is applied during it;

[0080] (2) Vacuum up to 10 -4 ...

Embodiment 2

[0102](1) Weigh 5g of pure silicene, mix it with gallium metal powder, press it into a cake shape, put it into a graphite boat, and put the sample boat into a reaction chamber with a stainless steel shell. This reaction chamber has a high-hydrogen dilute methane gas The reactant nozzle is located in the center directly above the reaction chamber to generate enhanced plasma. The nozzle is 20cm away from the center of the bottom of the reaction chamber; there is a magnetron sputtering inert gas nozzle at the top 5-10cm away from the center, which can Adjust the silicene target aligned to the center of the sample boat;

[0103] (2) Vacuum up to 10 -3 mTorr;

[0104] (3) Heat the sample boat to 1000-1200°C;

[0105] (4) Turn on the inert gas high-purity argon spray gun to inject argon, aim at the target in the sample boat, keep the sputtering power at 90-200W, and the working pressure at 0.1-1mTorr to produce silicene nuclei or silicene quantum dots , turn on the plasma generat...

Embodiment 3

[0122] Electrodes were made from this silicene sample. The steps are: (1) Weigh the silicon carbene sample, PVDF and graphene conductive agent so that the weight percentage is (80-90): (10-5): (10-5), and put them in a stainless steel stirrer; (2) Add 5ml of nmp to the sample in the agitator, and stir evenly in the vacuum agitator for 72 hours; (3) After taking it out, apply it to the foamed nickel; (4) Put the foamed nickel in the central control drying box , dried at 120°C for 72 hours, and cooled to room temperature; (5) Take out the nickel foam coated with the silicene sample and press it into a sheet on a roller press to prepare 200 CR2025 electrode sheets. Assemble the 200 electrode sheets as button cells, the counter electrode is a lithium-sodium alloy metal sheet, add a diaphragm, pour lithium ion and sodium ion electrolyte, and contain NaPF6 ethyl carbonate; seal and make 200 CR2025 buttons Lithium-sodium alloy / silicon carbene (or silicon carbide) battery. After agi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com