Pyrite-based composite material as well as preparation method and application thereof

A technology of composite materials and pyrite, which is applied in the field of pyrite-based composite materials and its preparation, can solve the problems of poor cycle stability and rate performance, low battery durability and cycle performance, and poor electrochemical performance. High specific capacity, long cycle life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to the present invention, the preparation method of the pyrite-based composite material comprises the following steps:

[0037] Step 1. Prepare pyrite powder.

[0038] According to the present invention, in step 1, the particle size of the obtained pyrite powder is 1-10 μm, preferably 1-5 μm, for example 2 μm.

[0039] According to the present invention, in step 1, pyrite powder can obtain through the following steps:

[0040] Step 1.1, grinding the pyrite;

[0041] Step 1.2, solid-liquid separation to obtain pyrite powder.

[0042] According to the present invention, in step 1.1, the pyrite is natural pyrite, and the natural pyrite is preferably taken from Shaoguan, Guangdong, and is preferably flotation pyrite in a concentrator, with a particle size of several hundred microns to several millimeters.

[0043] According to the present invention, in step 1.1, the pyrite is added to the solvent before grinding to form a suspension with a pyrite mass percentag...

Embodiment 1

[0088] Grinding the pyrite with a planetary ball mill to obtain a pyrite suspension, centrifuging and drying the pyrite suspension to obtain pyrite powder;

[0089] Add 5g of pyrite powder to 100ml of xanthate solution with a concentration of 2%, soak for 30min, stir, and then centrifuge at 12000rpm for 15min to obtain modified pyrite powder;

[0090] Add 4g of pyrite powder and 30g of phenolic resin into ethanol, stir and mix, then add them to a sand bath for heating and stirring, the heating temperature is 200°C, and the heating time is 10h. After the ethanol volatilizes, pyrite and A mixture of phenolic resins evenly mixed;

[0091] The mixture was placed in a high-temperature furnace, and subjected to high-temperature roasting in an argon atmosphere at a roasting temperature of 700° C. and a roasting time of 2 hours. After the roasting was completed, a pyrite-based composite material was obtained.

Embodiment 2

[0093] 10g of pyrite powder was added to 100ml of xanthate solution with a concentration of 0.2%, soaked for 60min, accompanied by stirring, and then centrifuged at a speed of 15000rpm for 10min to obtain modified pyrite powder;

[0094] Add 2g of pyrite powder and 30g of phenolic resin into ethanol, stir and mix, then add them to a sand bath for heating and stirring, the heating temperature is 100°C, and the heating time is 24h. After the ethanol volatilizes, pyrite and A mixture of phenolic resins evenly mixed;

[0095] The mixture was placed in a high-temperature furnace, and subjected to high-temperature roasting in an argon atmosphere at a roasting temperature of 600° C. and a roasting time of 3 hours. After the roasting was completed, a pyrite-based composite material was obtained.

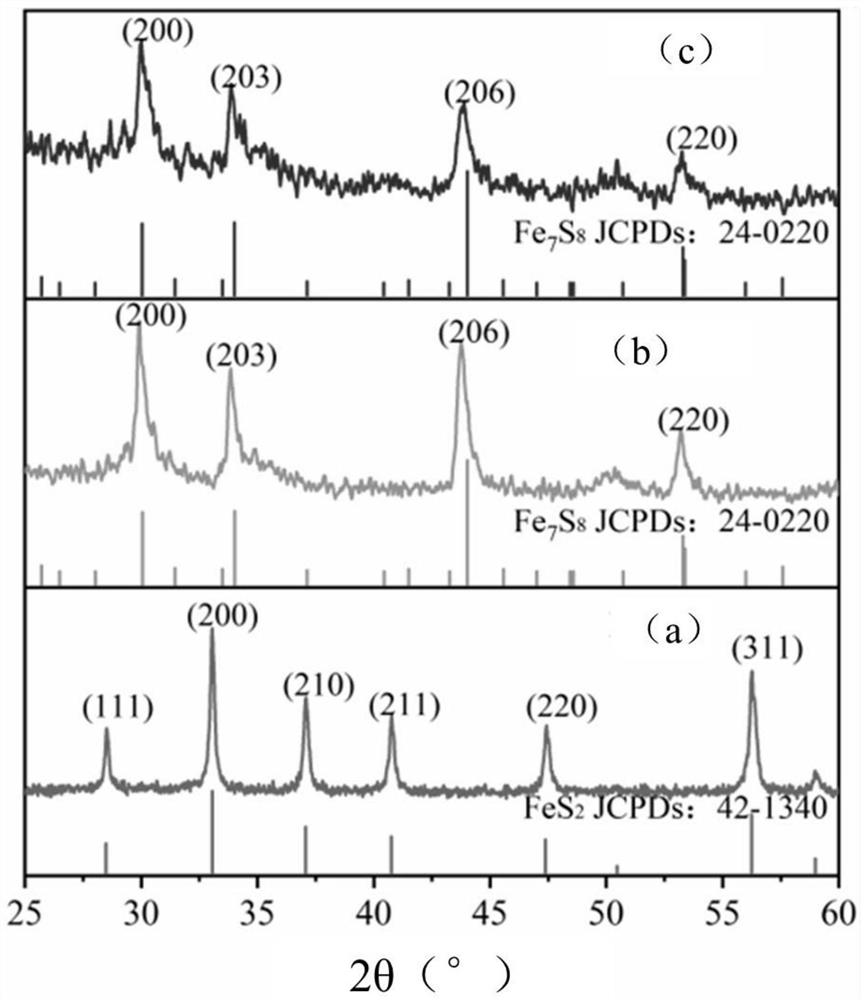

[0096] The pyrite powder prepared in embodiment 1 and the obtained pyrite-based composite material of embodiment 1 and 2 are carried out XRD test (using Bruker D8 X-ray diffractometer), the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com