Composite oil film-wrapped low-freezing point material spray liquid for asphalt pavement and preparation method

A technology for asphalt pavement and compound oil, which is applied in asphalt coatings, chemical instruments and methods, and other chemical processes, etc., can solve the problems of limited application, shortened service life of melting ice and snow pavement, and easy demulsification and precipitation of salts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the composite oil film-wrapped low-freezing point material spray liquid for asphalt pavement of the present invention comprises the following steps:

[0025] A. First, the mass ratio of 85-90 parts of asphalt (using one of coal tar pitch, petroleum pitch or natural asphalt, base asphalt can be used) and 8-12 parts of waste engine oil with a mass ratio of 2-3 parts of kerosene ( D80 solvent oil, D60 solvent oil or D40 solvent oil) are evenly and accurately weighed according to the proportion, stirred in a heating furnace, the temperature is 50-60°C, and the stirring time is 20-30min. covering liquid;

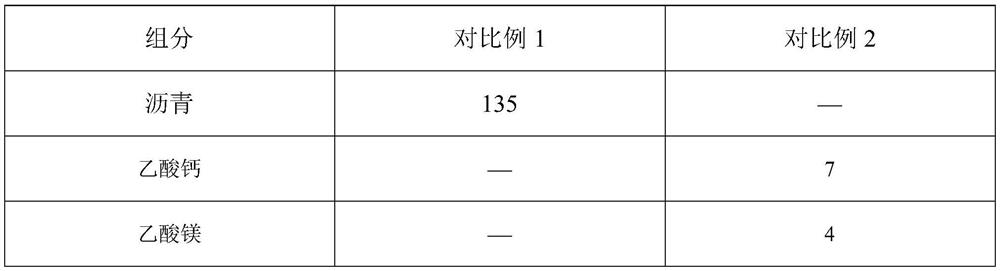

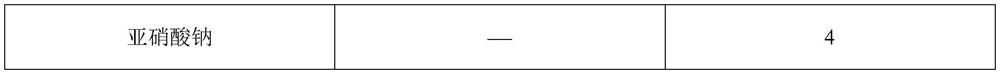

[0026] B. Fully mix the low-freezing point material coating solution obtained in step A, 7 parts of calcium acetate, 4 parts of magnesium acetate and 4 parts of sodium nitrite according to the mass ratio, and use the heating furnace again at a temperature of 50-60 ° C, and the stirring time is After stirring for 8-15 minutes, use a sieve to filte...

Embodiment 1

[0032] A. The mass ratio of 88 parts of coal tar pitch and 10 parts of waste engine oil and the mass ratio of 2 parts of D80 solvent oil are uniformly and accurately weighed according to the proportion, mixed, stirred, and stirred at 60 ° C for 20 minutes to obtain a low freezing point material coating liquid;

[0033] B. Fully mix the low-freezing point material coating liquid, 7 parts of calcium acetate, 4 parts of magnesium acetate and 4 parts of sodium nitrite according to the mass ratio, stir at 50°C for 10 minutes, filter out the solid particles with a sieve and dry them to obtain a composite oil film package Type low freezing point material;

[0034] C. Mix 50 parts of coal tar pitch, 1.0 part of fast-cracking and fast-setting emulsifier BH-K, 49 parts of water at 60°C, and 0.01 part of dilute hydrochloric acid in a mass ratio, and use a colloid mill to prepare emulsified pitch;

[0035] D. Fully mix the composite oil film-wrapped low-freezing point material obtained in...

Embodiment 2

[0037] A. The mass ratio of 85 parts of coal tar pitch and 12 parts of waste engine oil and the mass ratio of 2.5 parts of D80 solvent oil are evenly and accurately weighed according to the proportion, mixed, stirred, and stirred at 55°C for 25 minutes to obtain a low freezing point material coating liquid;

[0038] B. Fully mix the low-freezing point material coating solution, 7 parts of calcium acetate, 4 parts of magnesium acetate and 4 parts of sodium nitrite according to the mass ratio, stir at 55 °C for 12 minutes, filter out the solid particles with a sieve and dry them to obtain a composite oil film wrap Type low freezing point material;

[0039] C. Mix 50 parts of coal tar pitch, 0.6 part of fast-cracking and fast-setting emulsifier BH-K, 49 parts of water at 70°C, and 0.02 part of dilute hydrochloric acid in a mass ratio, and use a colloid mill to prepare emulsified pitch;

[0040] D. Fully mix the composite oil film-wrapped low-freezing point material obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com