Preparation method of MoNiB metal ceramic thread element

A technology of threaded components and cermets, which is applied in the direction of engine components, other manufacturing equipment/tools, turbines, etc., can solve the problems of non-durability and uneconomical, and achieve the effect of uniform distribution, high bending strength and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

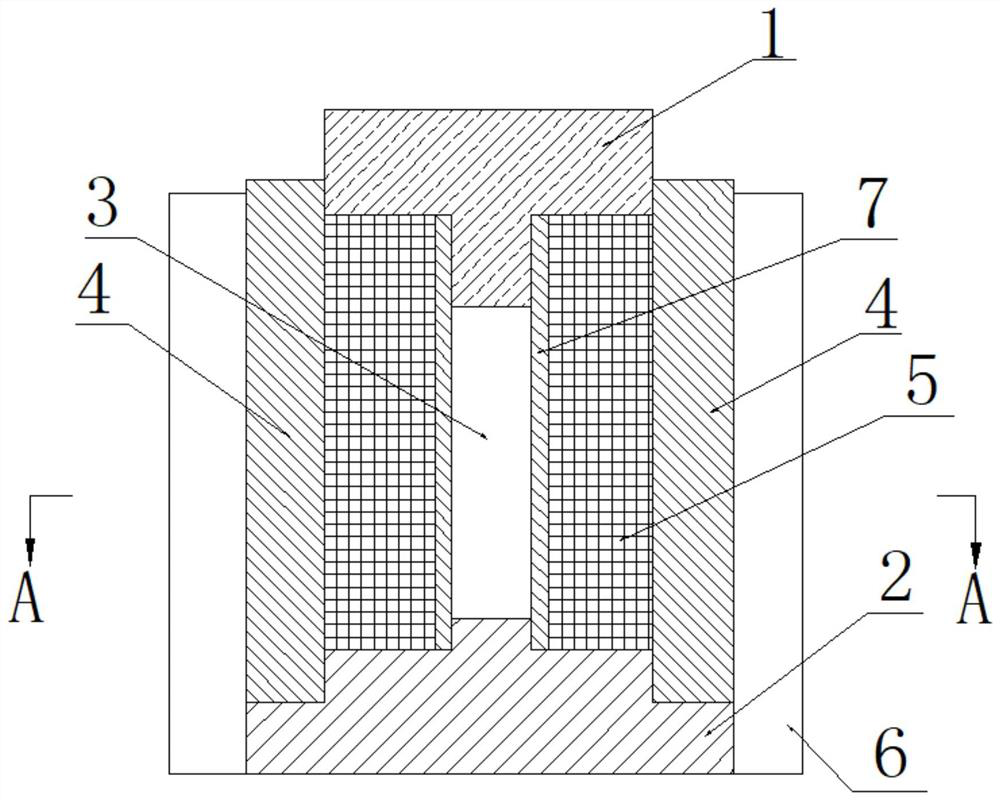

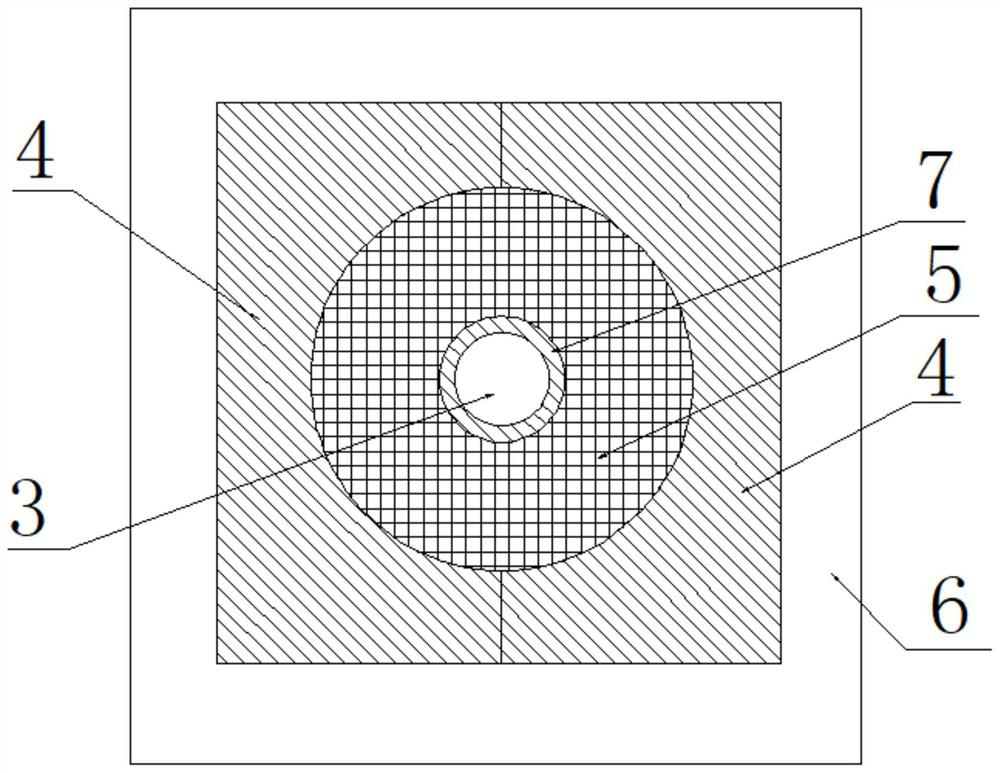

[0034] A preparation method of a MoNiB cermet screw element, comprising the following steps:

[0035] Step 1, with nickel-chromium alloy powder, molybdenum boride alloy powder, nickel boride alloy powder, molybdenum powder, Cr 2 C 3 Or VC or TiC powder, nickel powder as raw materials, and add a binder for ball milling, and then dry and sieve to obtain Mo-Ni-B metal mixed powder;

[0036] Among them, according to the mass percentage, the content of each raw material is: 12.5-27.5% nickel-chromium alloy powder, 40.0-60.0% molybdenum boride alloy powder, 0.5-2.5% nickel boride alloy powder, 0.1-15.0% molybdenum powder, 1.0- 3.0%Cr 2 C 3 / VC / TiC powder and the rest of nickel powder, plus an adhesive of 1.5-5.5% by mass of the above-mentioned raw materials, the adhesive is paraffin, polyvinyl alcohol or methyl cellulose;

[0037] During ball milling, a liquid hydrocarbon solvent is added to the raw material. The liquid hydrocarbon solvent is one or more of n-hexane, n-heptane, ...

Embodiment 1

[0049] Step 1a: Mix 40.0% molybdenum boride alloy powder, 2.0% nickel boride alloy powder, 16.0% nickel-chromium alloy powder, 13.0% Mo powder, and 2.0% VC nickel powder in the balance by mass percentage, plus the total mass of the above-mentioned raw materials 2.5% paraffin wax adhesive and ball milling according to the ball material ratio of 1:1, the ball milling agent is n-hexane, the ball milling time is 40 hours, the speed is 300 rpm, vacuum dried and sieved into Mo-Ni-B Metal-ceramic mixed powder;

[0050] Step 1b: Put the Mo-Ni-B metal mixed powder in step 1a into a metal mold, seal and vibrate, press the static pressure of 180Mpa, and hold the pressure for 30 minutes to form a prototype integral Mo-Ni-B metal blank;

[0051] Step 1c: Machining the static pressure formed Mo-Ni-B metal rod blank in step 1b into a thread blank, vacuum sintering the Mo-Ni-B metal thread blank, the sintering temperature is 1160°C, the heat preservation and sintering time is 30 minutes, vacu...

Embodiment 2

[0054] Step 2a: 59.0% molybdenum boride alloy powder, 1.0% nickel boride alloy powder, 19.0% nickel-chromium alloy powder, 0.1% Mo powder, 2.5% Cr by mass percentage 2 C 3 Mix with the remaining amount of nickel powder, add paraffin wax adhesive of 3.5% of the total mass of the above-mentioned raw materials, and then ball mill and mix according to the ball material ratio of 1:2. The ball milling agent is kerosene, the ball milling time is 60 hours, and the speed is 280 rpm. Vacuum drying and sieving into Mo-Ni-B metal mixed powder;

[0055] Step 2b: Put the Mo-Ni-B metal mixed powder in step 2a into a metal mold, place a steel rod core in the middle, vibrate and seal it, and form a steel core Mo-Ni through static pressure of 150Mpa and holding pressure for 20 minutes -B metal blank;

[0056] Step 2c: Machining the static pressure formed steel core Mo-Ni-B metal blank in step 2b into a thread blank, vacuum sintering the Mo-Ni-B metal thread blank, the sintering temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com