High-thermal-conductivity cobalt powder and preparation method thereof

A technology of cobalt powder and high conductivity, applied in the field of high thermal conductivity cobalt powder and its preparation, can solve problems such as difficult uniform dispersion, low reactivity, agglomeration, etc., to improve reactivity and purity, easy to operate, and improve conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

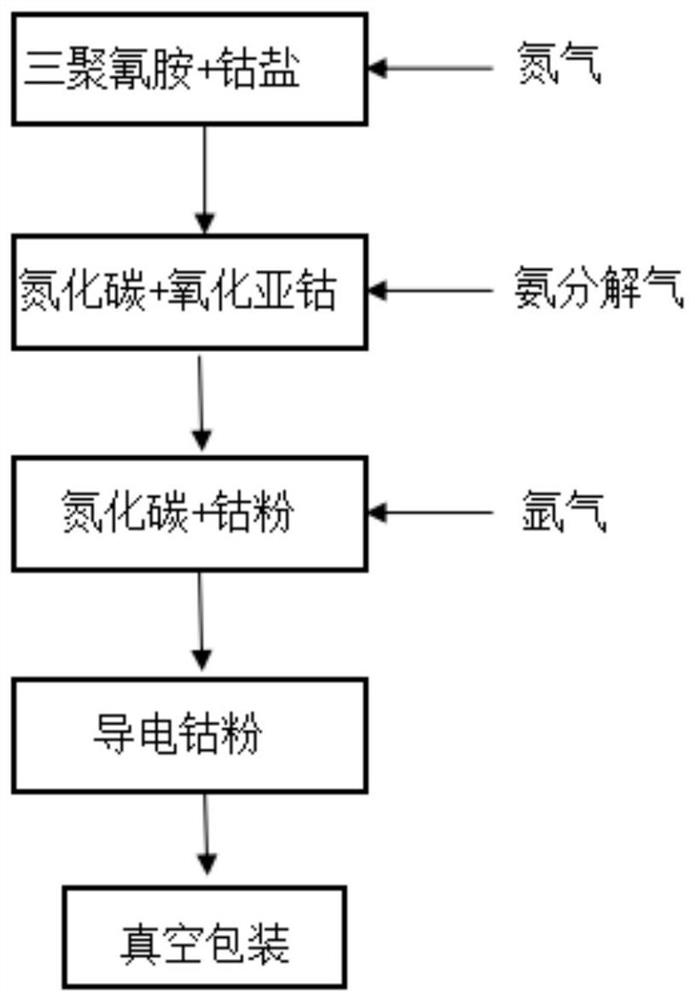

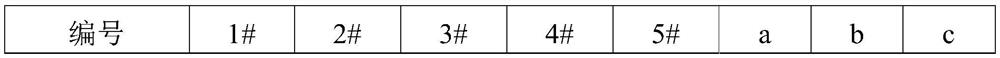

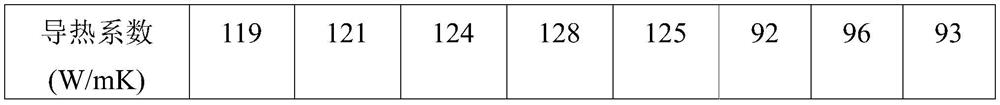

[0030] (1) Weigh the corresponding melamine and cobalt oxalate according to the weight ratio of 1.0%, grind and mix them evenly in a mortar, put the mixture in a quartz boat, raise the temperature to 250°C for 1h in nitrogen, and then raise the temperature to 520°C for 3h , to obtain a compound of nitrogen carbide and cobaltous oxide;

[0031] (2) Calcining and reducing the above-mentioned composite of nitrogen carbide and cobaltous oxide in an atmosphere of decomposing ammonia at 400°C for 4 hours to obtain a composite of nitrogen carbide and cobalt powder;

[0032] (3) The composite of the above-mentioned nitrogen carbide and cobalt powder was kept at 800° C. for 2 hours in an argon atmosphere, and finally a highly conductive cobalt powder composited with graphene and carbon nanotubes was obtained.

Embodiment 2

[0034] (1) Weigh the corresponding melamine and cobalt carbonate according to the weight ratio of 5.0%, grind and mix them evenly in a mortar, put the mixture in a quartz boat, heat up to 300°C in a mixed gas of nitrogen and argon for 1 hour, and then heat up Keep at 550°C for 2 hours to obtain a composite of nitrogen carbide and cobaltous oxide;

[0035] (2) Calcining and reducing the composite of the above-mentioned nitrogen carbide and cobaltous oxide in an atmosphere of decomposed ammonia at 450°C for 5 hours to obtain a composite of nitrogen carbide and cobalt powder;

[0036] (3) The composite of the above-mentioned nitrogen carbide and cobalt powder was kept at 850° C. in an argon atmosphere for 2 hours, and finally a highly conductive cobalt powder composited with graphene and carbon nanotubes was obtained.

Embodiment 3

[0038] (1) Weigh the corresponding melamine and cobalt oxalate according to the weight ratio of 8.0%, grind and mix them evenly in a mortar, put the mixture in a quartz boat, raise the temperature to 260°C for 1 hour in argon, and then raise the temperature to 500°C to keep 2h, obtain the composite of nitrogen carbide and cobaltous oxide;

[0039] (2) Calcining and reducing the above-mentioned composite of nitrogen carbide and cobaltous oxide in an atmosphere of decomposing ammonia at 350°C for 6 hours to obtain a composite of nitrogen carbide and cobalt powder;

[0040] (3) The composite of the above-mentioned nitrogen carbide and cobalt powder was kept at 750° C. for 3 hours in an argon atmosphere, and finally a highly conductive cobalt powder composited with graphene and carbon nanotubes was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com