Preparation method of vinyl chloride-ethylene copolymer with network toughening structure

A technology of ethylene copolymer and vinyl chloride, applied in the field of functional polymers, can solve the problems of strong corrosion, environmental pollution, and many processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

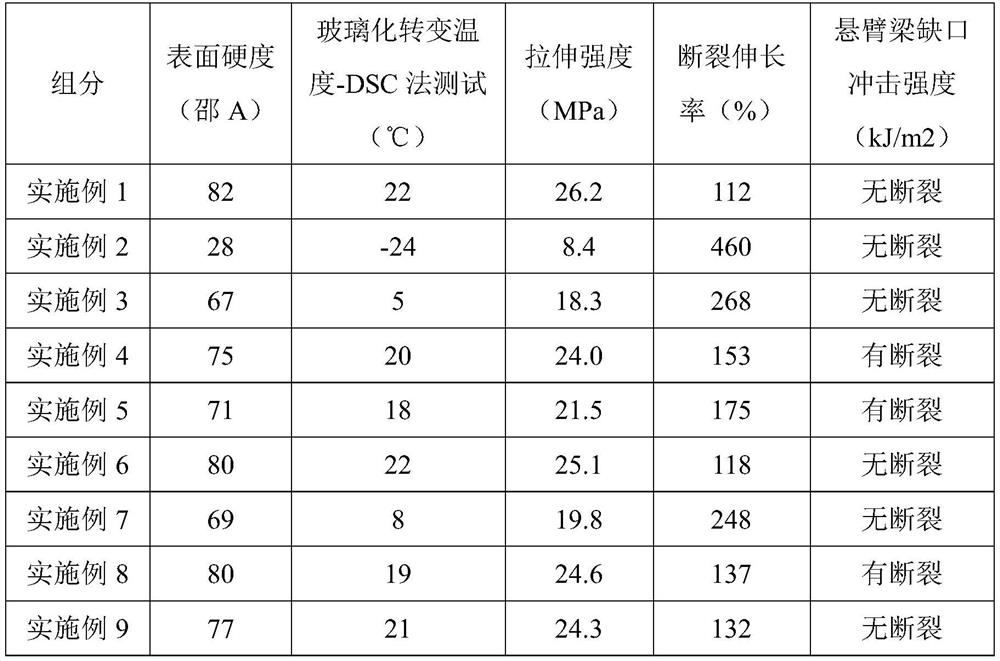

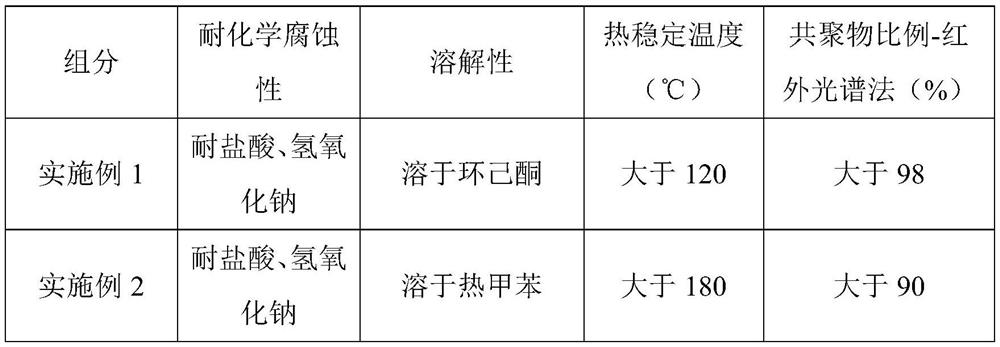

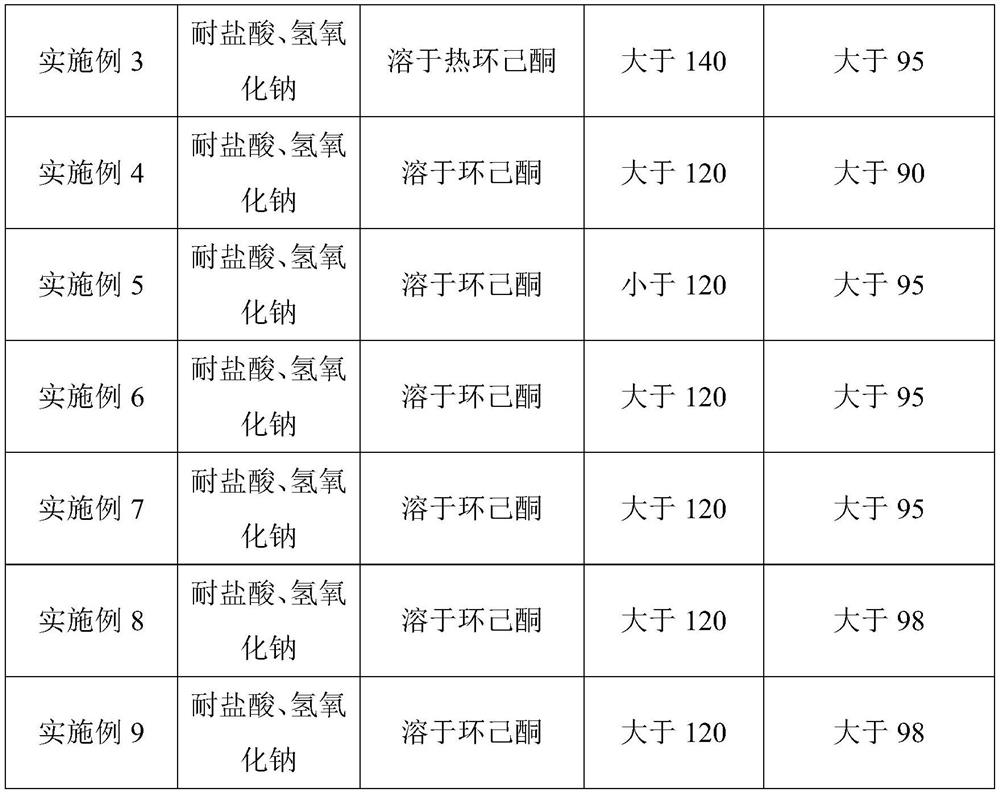

Examples

Embodiment 1

[0042] Embodiment 1 provides a kind of preparation of the preparation method of vinyl chloride-ethylene copolymer with network toughening structure, and step comprises:

[0043] (1) ethylene is mixed with a crystallization rate regulator to obtain modified ethylene monomer;

[0044] Add 100 parts by mass of compressed liquefied ethylene, 0.01 part of fumed silica (Degussa AEROSIL300), 0.05 part of zinc dodecanoate and 0.1 part of polyoxyethylene ether into a high-pressure stirred tank, and Stir at 1000 rpm for 1 hour. Then, transfer it to the monomer storage tank for sealed storage to obtain a modified ethylene monomer mixture;

[0045] (2) Emulsion copolymerization of vinyl chloride and modified ethylene monomer;

[0046] 200 parts by mass of deionized water, 0.5 parts of peroxydicarbonate, 0.5 parts of sodium lauryl sulfate, 0.5 parts of dodecylphenol polyoxyethylene ether, 0.1 parts of Polyvinyl alcohol, 0.1 part of sodium bicarbonate and 0.01 part of thioglycolic acid w...

Embodiment 2

[0050] Embodiment 2 provides a kind of preparation of the preparation method of vinyl chloride-ethylene copolymer with network toughening structure, and step comprises:

[0051] (1) ethylene is mixed with a crystallization rate regulator to obtain modified ethylene monomer;

[0052] Put 100 parts by mass of compressed liquefied ethylene, 0.25 parts of 1,3;2,4-bis-o-(benzylidene) sorbitol, 0.25 parts of zinc oxide and 0.5 parts of lauric acid into the high-pressure stirring tank , stirred at 2000 rpm for 2 hours at room temperature. Then, transfer it to the monomer storage tank for sealed storage to obtain a modified ethylene monomer mixture;

[0053] (2) Emulsion copolymerization of vinyl chloride and modified ethylene monomer;

[0054] 250 parts by mass of deionized water, 1.5 parts of aluminum-titanium-based Ziegler-Natta catalyst, 1 part of sodium dodecylbenzenesulfonate, 1.5 parts of nonylphenol polyoxygen Vinyl ether, 0.5 part of hydroxypropyl cellulose, 0.5 part of po...

Embodiment 3

[0058] Embodiment 3 provides a kind of preparation of the preparation method of vinyl chloride-ethylene copolymer with network toughening structure, and step comprises:

[0059] (1) ethylene is mixed with a crystallization rate regulator to obtain modified ethylene monomer;

[0060] Add 100 parts by mass of compressed liquefied ethylene, 0.1 part of nano-calcium carbonate, 0.1 part of calcium stearate and 0.15 part of polyacrylamide into a high-pressure stirred tank, and stir at room temperature at 1000 rpm for 1 hour. Then, transfer it to the monomer storage tank for sealed storage to obtain a modified ethylene monomer mixture;

[0061] (2) Emulsion copolymerization of vinyl chloride and modified ethylene monomer;

[0062]200 parts by mass of deionized water, 1 part of zirconium-titanium-based metallocene catalyst, 0.5 part of sodium dodecyl sulfate, 1.5 parts of dodecylphenol polyoxyethylene ether, 0.15 parts of Part of sodium carboxycellulose, 0.25 part of ammonia water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com