Partition plate rectification process and apparatus for propargyl alcohol and butynediol aqueous solution system

A rectification technology of butynediol and clapboard, which is applied to the rectification and separation of butynediol aqueous solution and the field of propynyl alcohol, which can solve the problems of no energy saving and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

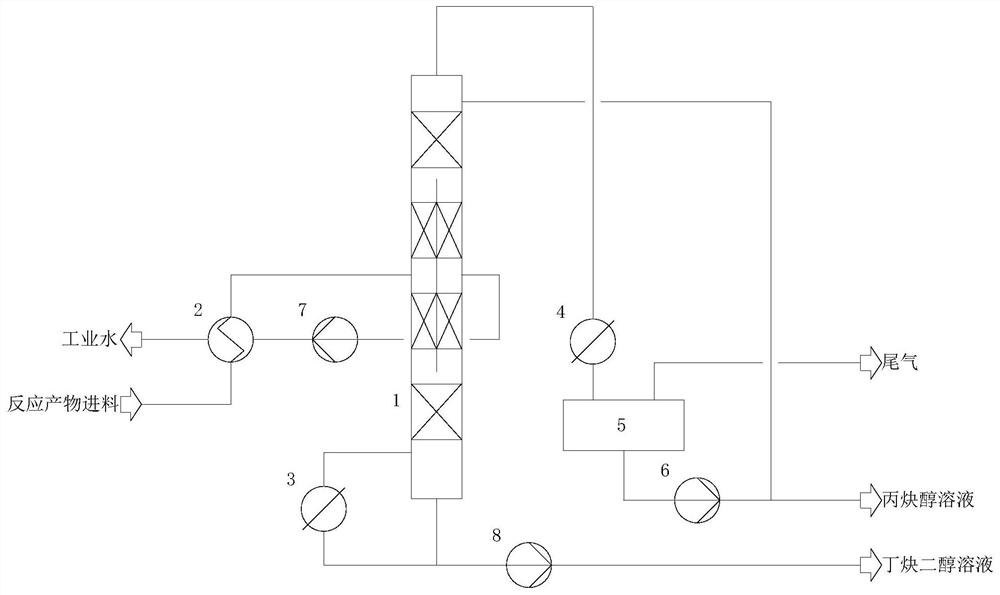

Image

Examples

example 1

[0026] The feed flow rate is 2t / h, the reaction selectivity ratio of propynyl alcohol and butynediol is 0.99, the water content is 89.3%, the feed temperature is 35°C, and the pressure of the feed reaches 0.2Mpag after being pressurized by a pump.

[0027] The 2t / h feed is heated to 50°C after passing through the preheater (2), and then sent to the middle part of the clapboard rectification tower (1). The upper part of the tower is filled with 6m mesh corrugated structured packing as a public rectification section, and the lower part is equipped with 5 layers The sieve tray is used as a common stripping section, and the middle part is divided by a 13.5m-high partition. The feed side is filled with 10m mesh corrugated structured packing for feed pre-separation, and the output side is filled with 8m mesh corrugated structured packing for products. Purification side mining. The diameter of the partition rectifying column (1) is 1000mm. The operating pressure is controlled at -0....

example 2

[0032] The feed flow rate is 4t / h, the reaction selectivity ratio of propynyl alcohol and butynediol is 0.67, the water content is 90.46%, the feed temperature is 35°C, and the feed pressure reaches 0.2Mpag after being pressurized by a pump.

[0033] The 4t / h feed is heated to 50°C after passing through the preheater (2), and then sent to the middle part of the clapboard rectification column (1). The upper part of the tower is filled with 6m mesh corrugated structured packing as a public rectification section, and the lower part is equipped with 5 layers The sieve tray is used as a common stripping section, and the middle part is divided by a 13.5m-high partition. The feed side is filled with 10m mesh corrugated structured packing for feed pre-separation, and the output side is filled with 8m mesh corrugated structured packing for products. Purification side mining. The diameter of the partition rectifying column (1) is 1400mm. The operating pressure is controlled at -0.03Mpa...

example 3

[0038] The feed flow rate is 6t / h, the reaction selectivity ratio of propynyl alcohol and butynediol is 1.54, the water content is 70%, the feed temperature is 20°C, and the feed pressure reaches 1.0Mpag after being pressurized by a pump.

[0039] The 6t / h feed is heated to 42°C after passing through the preheater (2), and sent to the middle part of the partitioned rectification column (1). The 2m random Pall ring packing is used as the common stripping section, and the middle part is divided by a partition with a height of 15m. The feed side is filled with 12m random Pall ring packing for feed pre-separation, and the output side is filled with 10m random abalone Er ring packing is used for product purification side mining. The diameter of the partition rectifying column (1) is 1600mm. The operating pressure is controlled at 0.2Mpag, the temperature at the top of the tower is 140°C, and the temperature at the bottom of the tower is 150°C.

[0040] The gas phase at the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com