External pressure type dry powder pump

A dry powder pump, external pressure technology, applied in conveyors, throwing machines, transportation and packaging, etc., can solve the problems of pressurized conveying of dry powder materials, lack of fluidity of liquid materials, easy jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

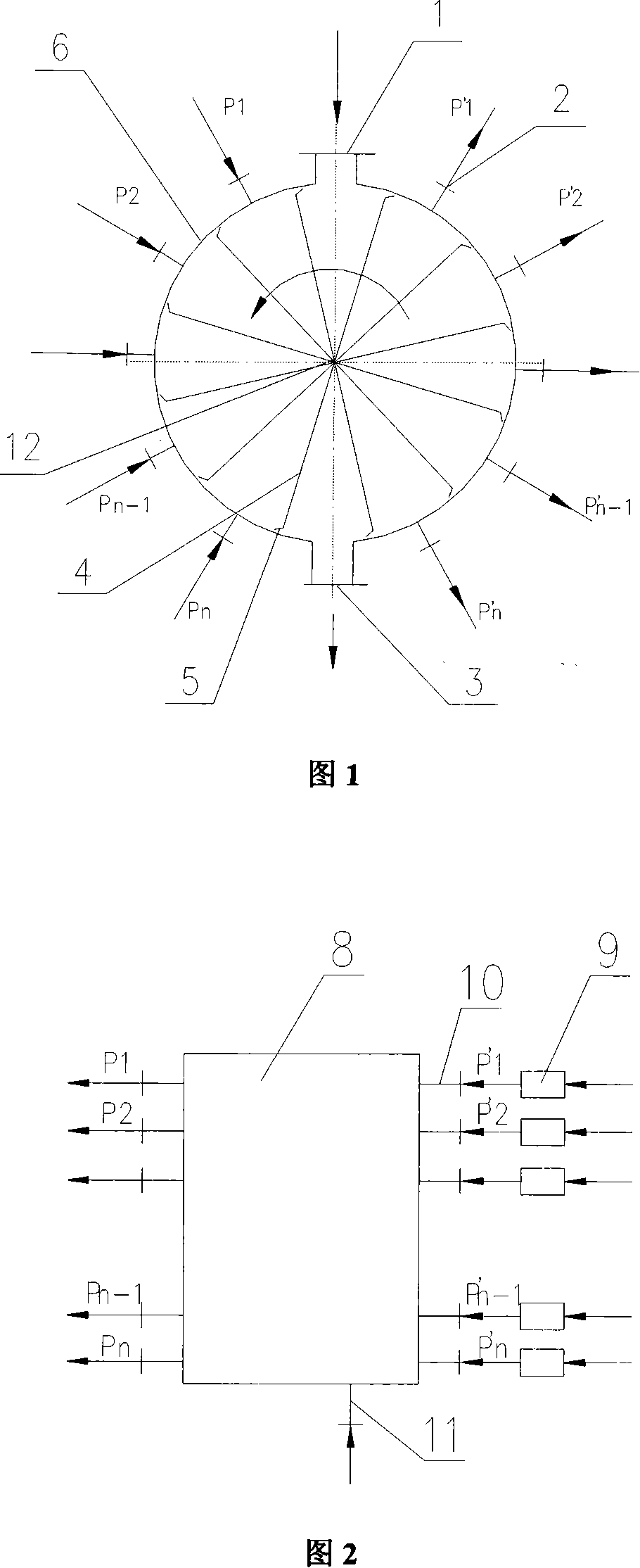

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings (FIG. 1-FIG. 2).

[0021] The invention relates to a device capable of pressurizing and transporting dry powdery substances. The invention solves the problem that current pumps (compressors) combine two processes of pressurization and delivery, and cannot pressurize and transport materials with high solid-liquid (gas) ratio. The external pressure dry powder pump of the present invention can connect the pump body and the variable pressure balance system, pressurize the dry powder material by the pressure variable balance system, and transport the dry powder material by the pump body and the rotor in the pump body. Due to the slow speed of the rotor, the multi-point pressure introduction of the variable pressure balance system, the small pressure difference between the adjacent dynamic variable pressure intervals, the sealing problem is easy to solve, and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com