Oil depot light hydrocarbon fuel oil adding and volatile gas recovering device

A technology of volatilizing gas and recovery device, applied in liquid distribution, transportation or transfer device, distribution device, special distribution device, etc., can solve the problems of large amount of refueling, long time required, large amount of gasification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

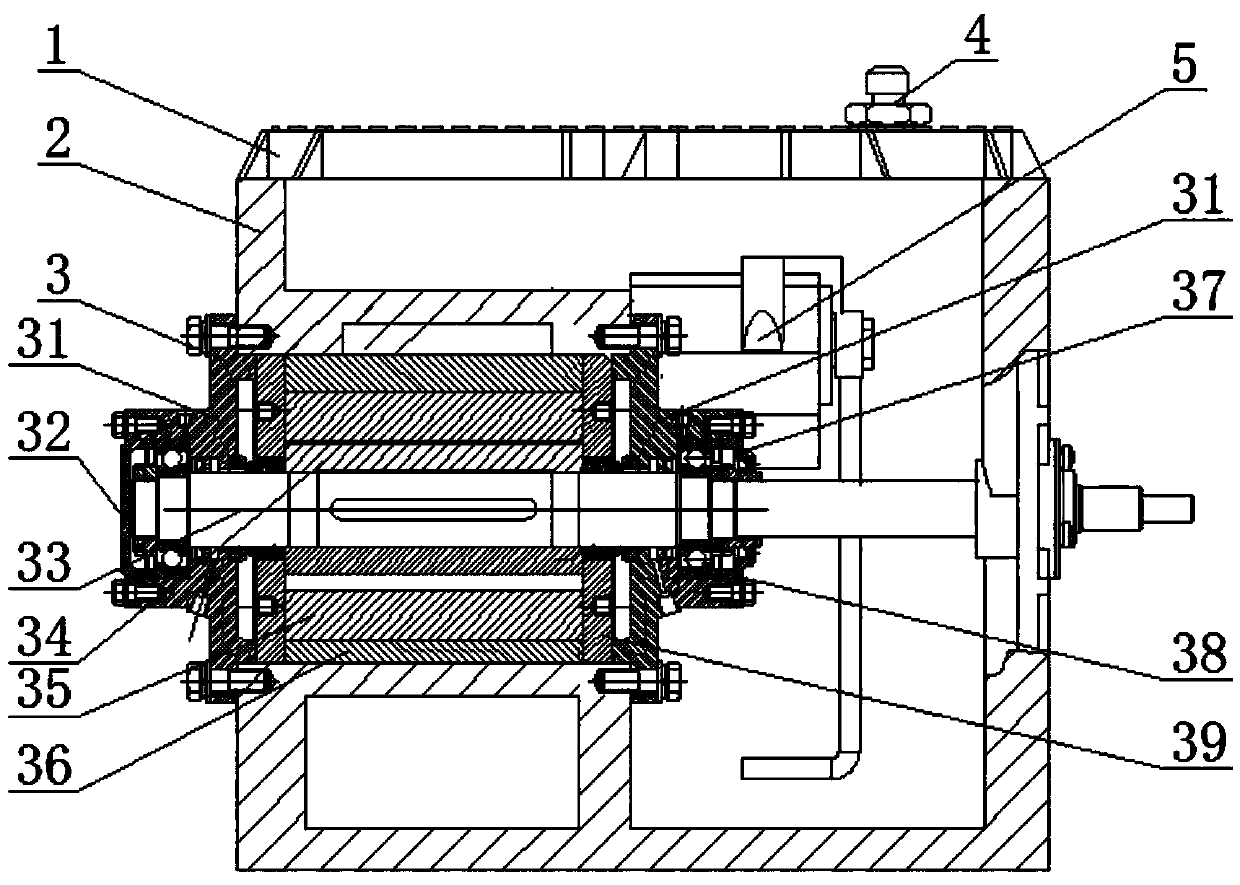

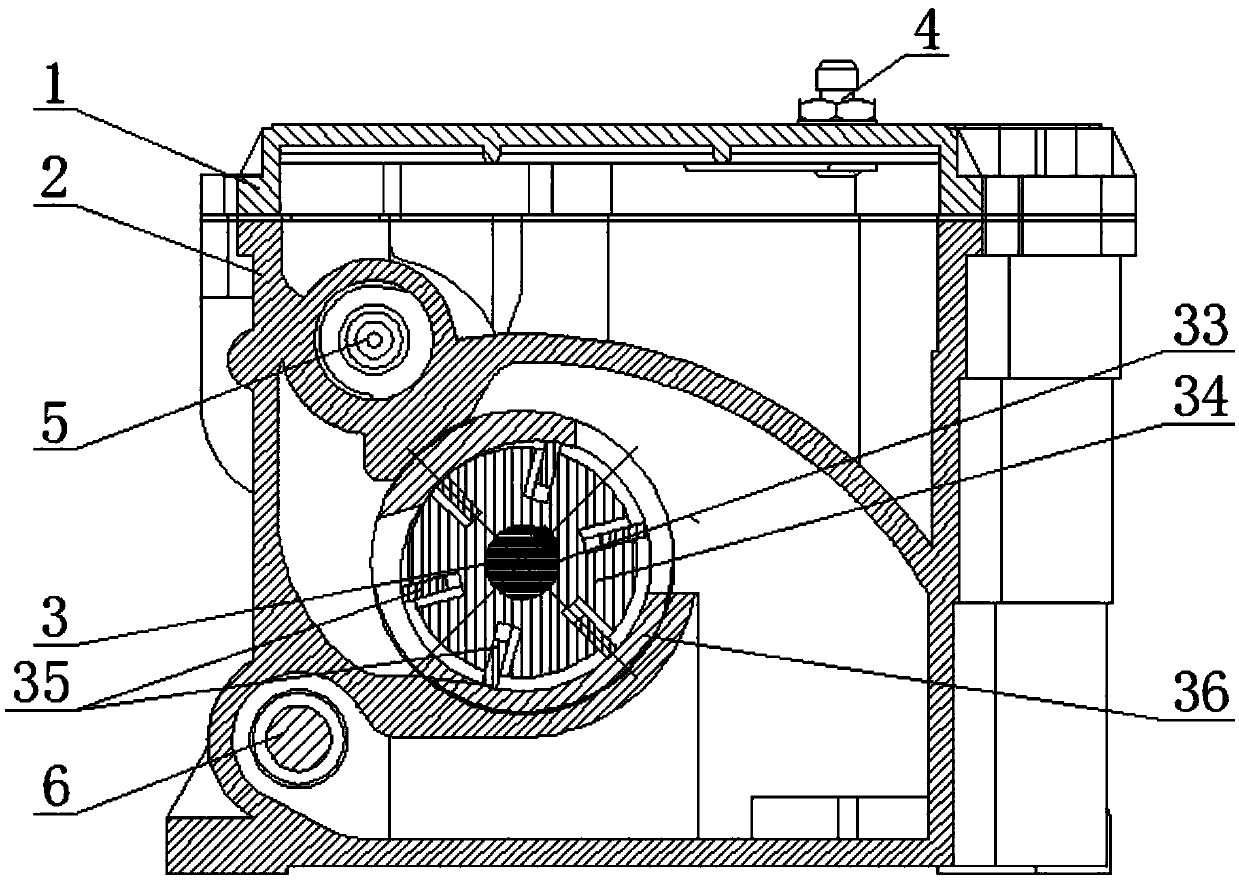

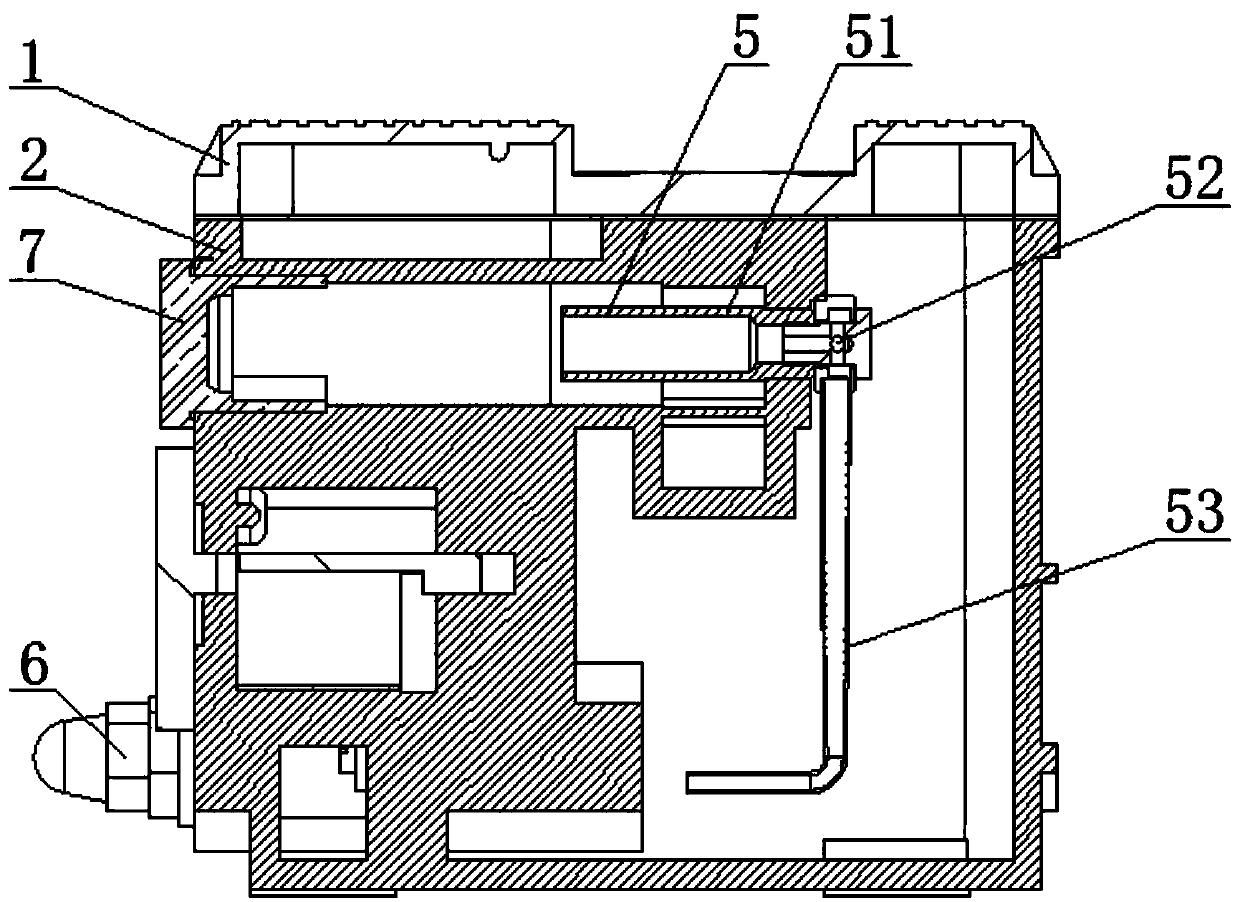

[0031] refer to Figure 1-Figure 17 , the present invention comprises a device cover 1, a device housing 2, a sliding vane pump 3, a pressure relief plug 4, an oil-gas separator 5, a safety valve 6, a separation chamber cover 7, a filter 8 and a buoyancy control valve 9, the device The cover 1 is installed on the device casing 2 through bolts, and a sliding vane pump 3 is installed horizontally inside the device casing 2; a pressure relief plug 4 is embedded above the device cover 1; Separator 5, a separation chamber cover 7 is installed on the device housing 2 on the left side of the oil-gas separator 5, and a safety valve 6 is arranged horizontally at the rear and lower part of the device housing 2; a liquid inlet 25 is provided at the front lower end of the device housing 2 , the liquid inlet 25 is fixed with a filter 8 by bolts; the bottom surface of the inner cavity of the device housing 2 is provided with a buoyancy control valve 9; the slide vane pump 3 includes a side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com