Valveless engine

An engine and valve technology, used in engine components, combustion engines, machines/engines, etc., can solve the problems of increased accident points, difficult manufacturing, low fuel efficiency, etc., to extend the overhaul interval, reduce accident points, and achieve sufficient combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

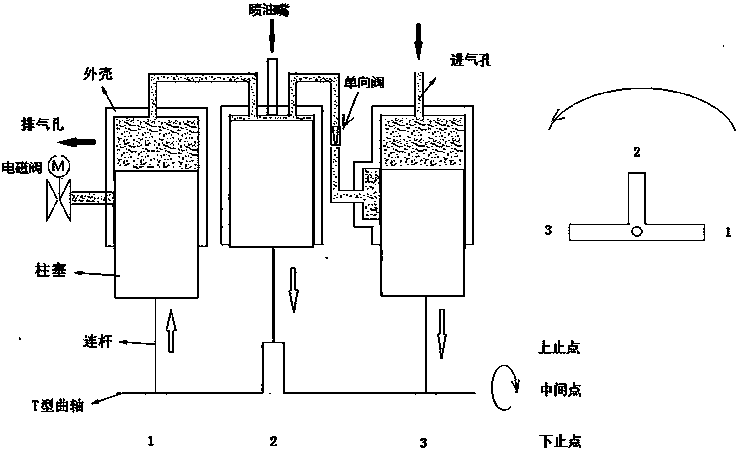

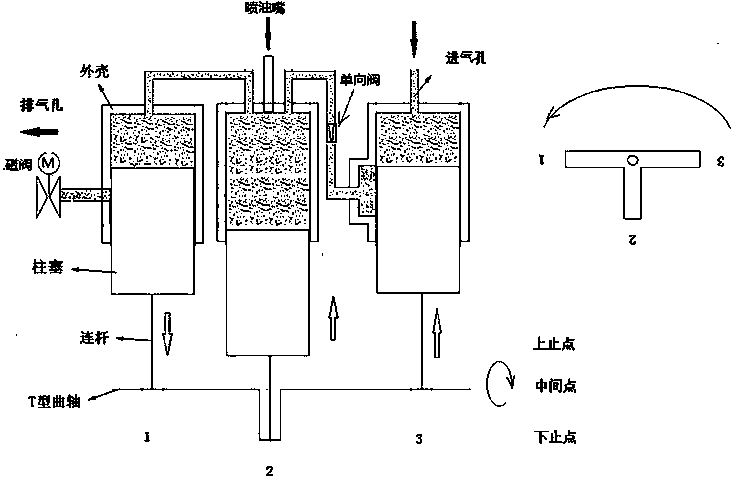

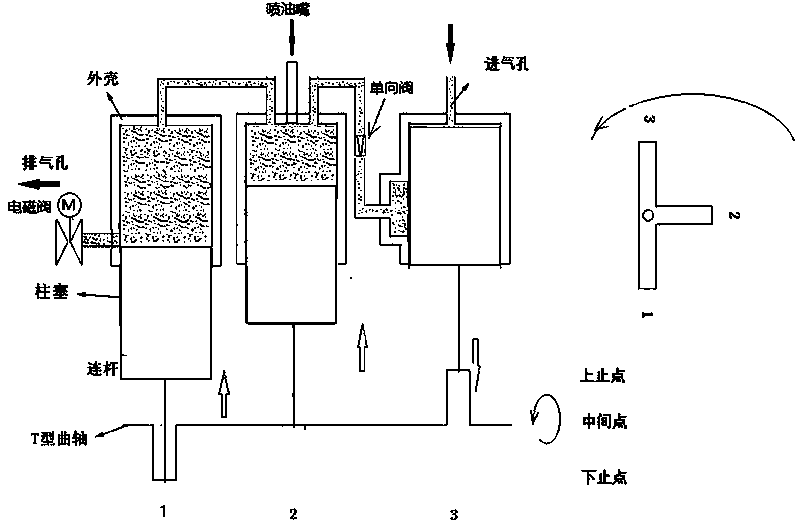

[0024] Such as image 3 As shown, the positions of the three plungers at the beginning, No. 1 and No. 3 plungers are at the middle point, and No. 2 plunger is at the top dead center. Figure 4 It is another connection method with the same principle.

[0025] The T-shaped crankshaft starts to move, the No. 2 plunger goes down, and the upper part of the plunger forms a vacuum suction force. Since the No. 3 plunger goes up, the mud inlet hole is blocked, and the No. 1 plunger goes down to open the fluid inlet hole, so the vacuum suction Force the mud through the No. 1 plunger into the No. 2 plunger. When the crankshaft rotates, the suction force of the No. 2 plunger makes the mud flow into the No. 2 plunger through the No. 1 plunger continuously. Rotate 90 0 arrive Figure 5 In this process, the mud entering No. 1 and No. 2 plungers is 0.5pv, a total of 1pv, and it is 0.5pv when No. 3 plunger is squeezed out of the pump.

[0026] The T-shaped crankshaft continues to rotate, ...

Embodiment 2

[0031] During the operation of the T-shaped crankshaft, it is easy to cause vibration due to asymmetry. Two or more sets of T-shaped crankshafts can be combined into a plunger pump with 6 or more plungers.

Embodiment 3

[0033] The volume of No. 2 plunger can be different from that of No. 1 and No. 3 plungers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com