Method for carrying out power outputting and gas conveying through low-temperature liquid

A low-temperature liquid and power output technology, which is applied in the field of gas transportation and low-temperature liquid power output, can solve problems such as large energy consumption, and achieve the effect of reducing energy consumption and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: power output

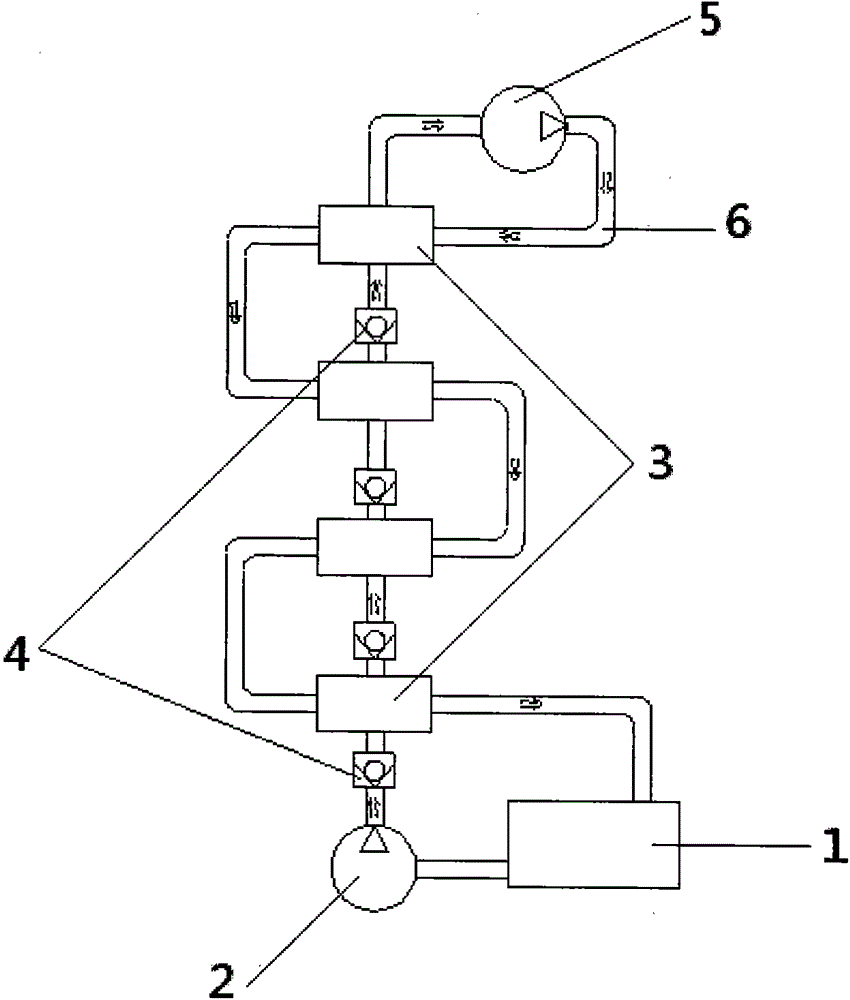

[0025] Such as figure 1 As shown, the low temperature heat preservation liquid storage tank 1 is filled with low temperature liquid, and the outlet of the low temperature heat preservation liquid storage tank is connected to the hydraulic pump 2 . The output port of the hydraulic pump is connected to the first-stage cooling and evaporating heat exchanger 3 through a one-way valve 4. The heat exchanger unit is called the final refrigeration evaporative heat exchanger. A one-way valve 4 is provided between the two-stage refrigeration evaporative heat exchanger units, and a check valve is connected to the inlet end of the first-stage refrigeration evaporative heat exchanger unit; The outlet is connected to the inlet of the pneumatic motor 5, and the outlet of the pneumatic motor 5 is connected to the circulation return pipe 6, and the circulation return pipe is connected to the low-temperature heat preservation liquid storage tank 1 through t...

Embodiment 2

[0028] Example 2: Gas delivery

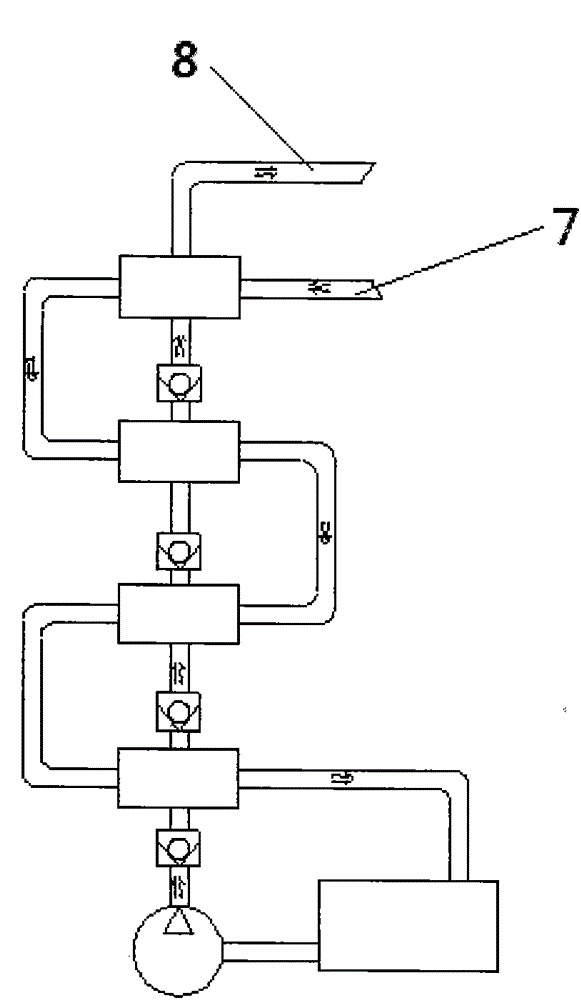

[0029] Such as figure 2 As shown, the structural difference between Embodiment 2 and Embodiment 1 is that the low-pressure gas input pipe 7 is connected to the final refrigeration evaporative heat exchanger unit, and the outlet of the final refrigeration evaporative heat exchanger unit is connected to the high-pressure gas output pipe 8 . The low-pressure gas passes through the last-stage refrigeration evaporative heat exchanger unit and begins to cool down step by step, until the outflow of the first-stage refrigeration evaporative heat exchanger unit has become a low-temperature liquid and enters the low-temperature insulation storage tank, and then passes through the hydraulic pump to transfer the low-temperature liquid from the The low-temperature heat preservation liquid storage tank is pumped out and pressed into the first-stage refrigeration evaporative heat exchanger unit, and the fourth-stage (last stage) refrigeration evaporative hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com