Double-wheel-set different-axis pressurizing mechanism for hot air welding machine and working method and using method of mechanism

A technology of hot air welding and pressing mechanism, which is applied in the field of hot melt welding, can solve the problems of easy folding and material slippage in welding, and achieve the effects of not easy folding, simple design, and easy maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

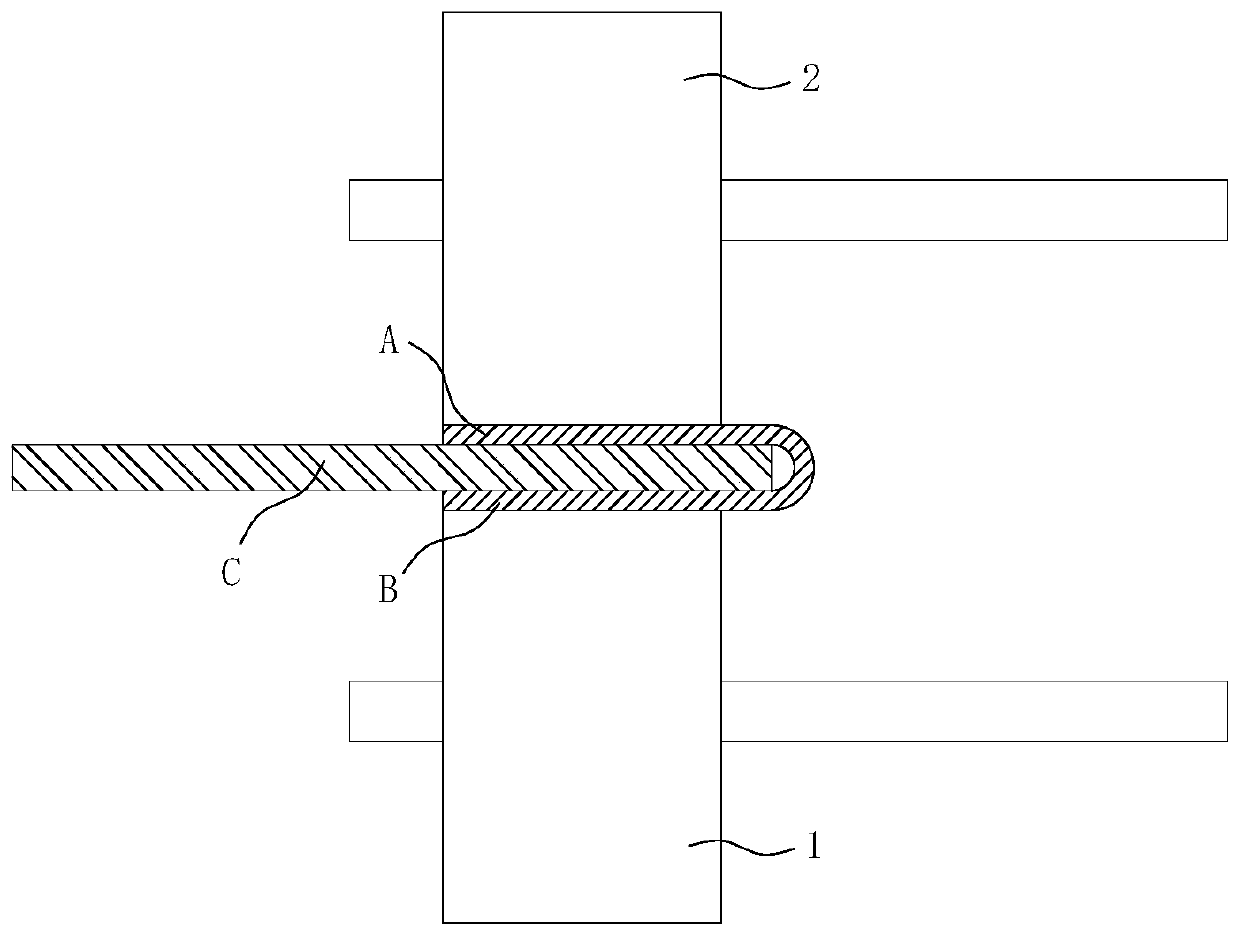

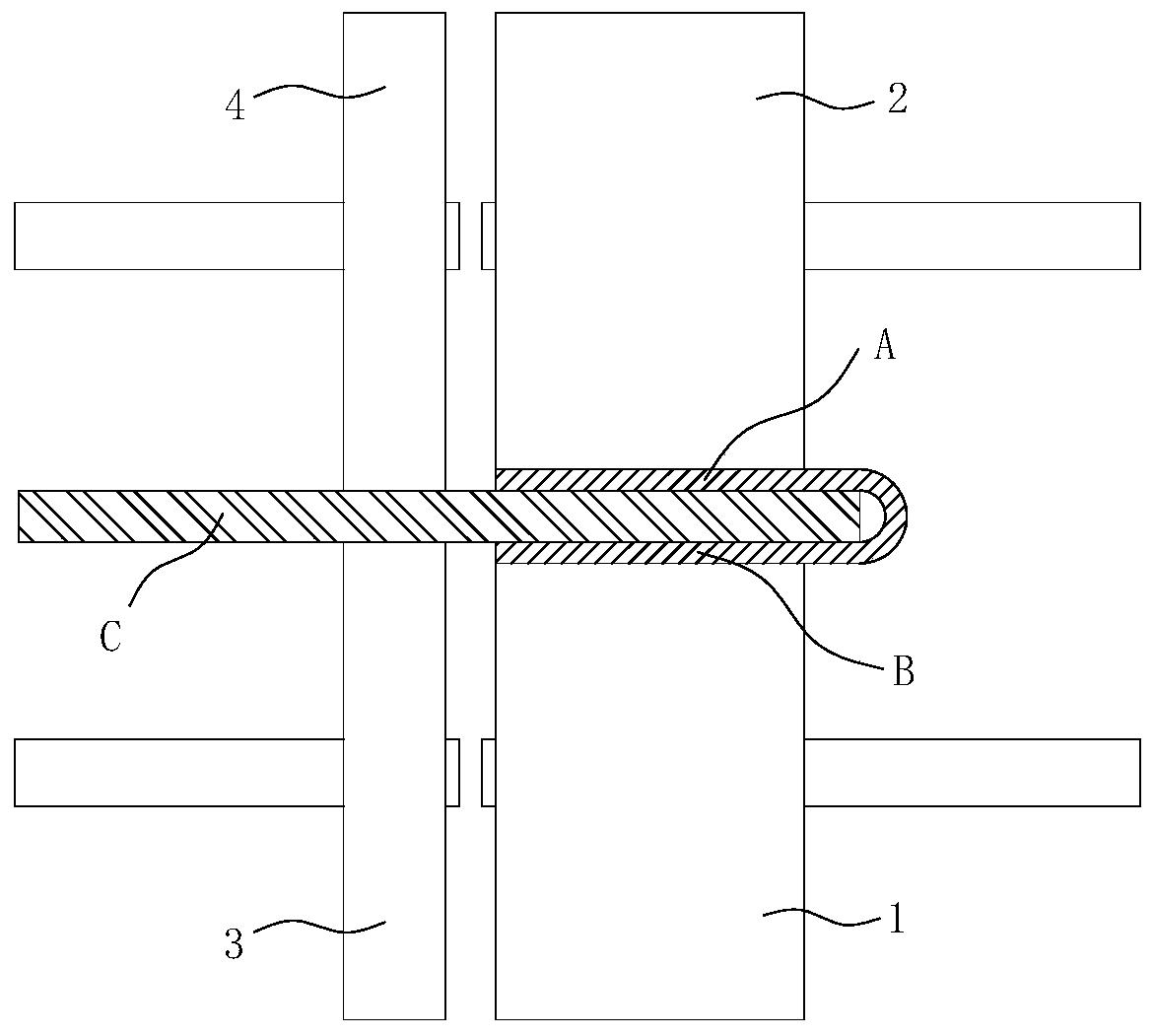

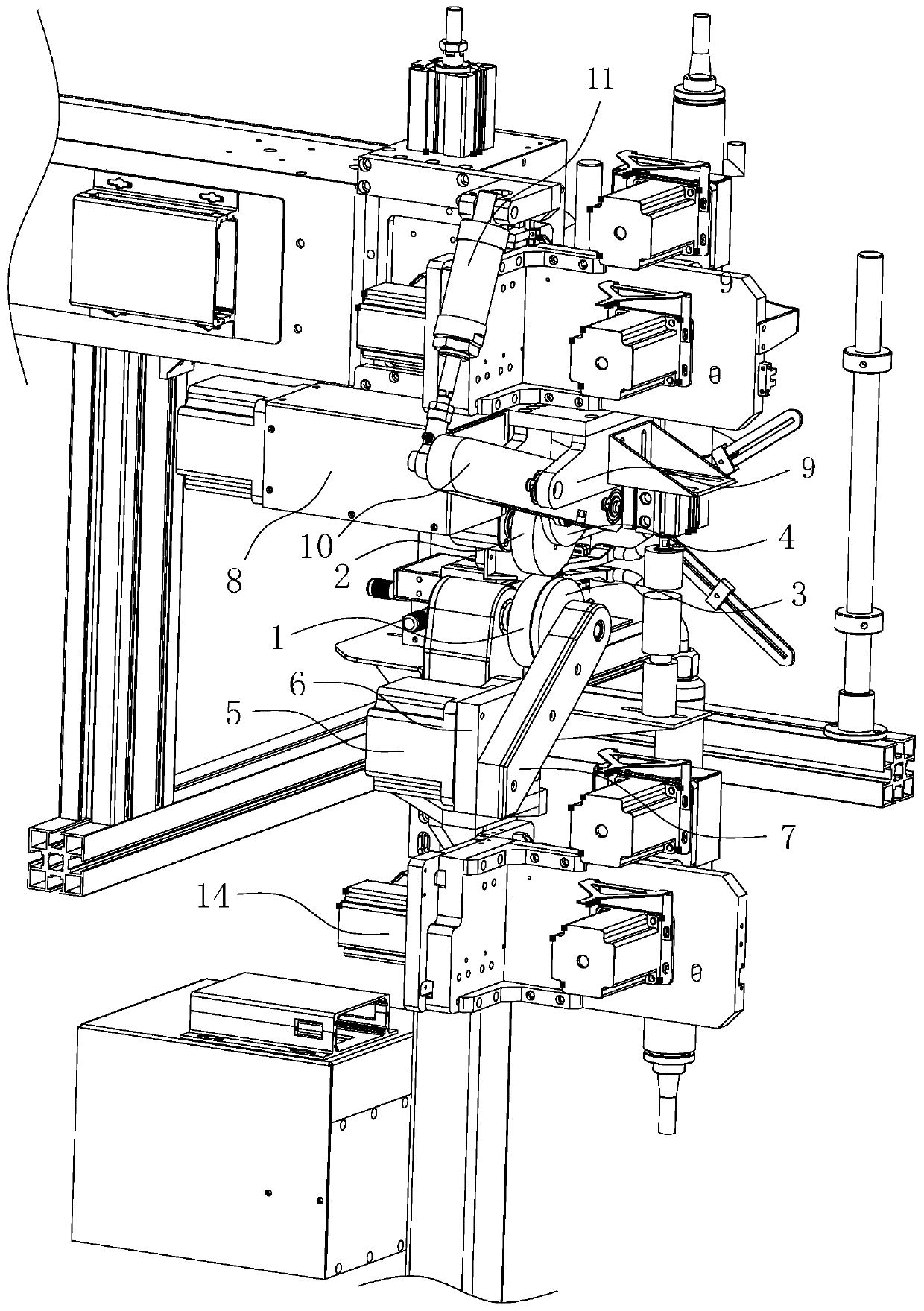

[0051] like Figure 2 to Figure 4 As shown, the dual-wheel set heteroaxial pressurizing mechanism for the hot air welding machine of this embodiment includes an upper frame 9 and a lower frame 6 . Rotate and set upper belt pulley 2 on the last frame 9, rotate and set lower belt pulley 1 on the lower frame 6. The upper and lower pulleys are set to rotate synchronously, which is suitable for pressurized conveying of the upper edge belt A, the outer section of the brushed cloth and the lower edge belt B that have been stacked. The two-wheel group heteroaxial pressurization mechanism also includes upper and lower material wheels that are rotated synchronously. The lower material wheel 3 is rotatably arranged on the lower frame 6, and the upper material wheel 4 is rotatably arranged on the upper frame 9. The upper and lower material wheels It is suitable for pressurizing and conveying the inner section of the passing brushed cloth. The lower pulley 1 and the upper pulley 2 have a...

Embodiment 2

[0062] like Figure 2 to Figure 7 As shown, on the basis of Embodiment 1, this Embodiment 2 provides a working method of a double-wheel set different-axis pressurization mechanism for a hot-air welding machine. Shaft pressurization mechanism is realized.

[0063] The lower feeding motor 5 drives the lower material wheel 3 to rotate through the lower transmission arm 7, the upper feeding motor 8 drives the upper material wheel 4 to rotate through the upper transmission arm 10, and the upper belt feeding motor 12 drives the upper belt pulley 2 to rotate through the upper transmission assembly 13, and the lower feeding motor 8 drives the upper belt wheel 2 to rotate through the upper transmission assembly 13. The belt feeding motor 14 drives the lower pulley 1 to rotate through the lower transmission assembly 15 .

[0064] The upper and lower material wheels and the upper and lower pulleys form a double-wheel structure and then rotate synchronously or differentially, so that the...

Embodiment 3

[0068] like Figure 2 to Figure 7 As shown, on the basis of Embodiment 1, this Embodiment 3 provides a working method of a double-wheel set different-axis pressurization mechanism for a hot-air welding machine. Shaft pressurization mechanism is realized.

[0069] Insert the stacked upper edging belt A, the outer section of the drawing cloth and the lower edging belt B into the anastomosis of the upper and lower pulleys, and the inner section of the drawing cloth is inserted into the anastomosis of the upper and lower material wheels. The belt wheel and the upper and lower material wheels rotate synchronously or at a differential speed to realize the pressurized conveying of the passing brushed cloth C and the upper and lower edging belts.

[0070] The beneficial effect of the present invention is that, the method for using the double-wheel set different-axis pressing mechanism for the hot-air welding machine of the present invention adopts the aforementioned double-wheel set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com