Carbon dioxide sensor for monitoring microbial growth and preparation method thereof

A carbon dioxide, sensor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of low utilization, limited use, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

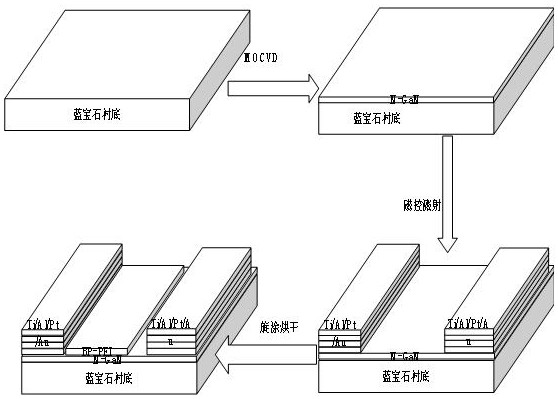

[0040] A preparation method for a carbon dioxide sensor for monitoring microbial growth, comprising the steps of:

[0041] Step 1: epitaxially grow silicon-doped n-type gallium nitride epitaxial wafers on a sapphire substrate;

[0042] Step 2: Deposit a SiO2 layer on the surface of the n-type gallium nitride epitaxial wafer by PECVD method, place a mask after removing the photoresist, and prepare an in-situ mask by using exposure and development processes;

[0043] Using magnetron sputtering technology to deposit Ti / Al / Pt / Au electrodes on the surface of n-type GaN epitaxial wafers to form ohmic contact with GaN epitaxial wafers;

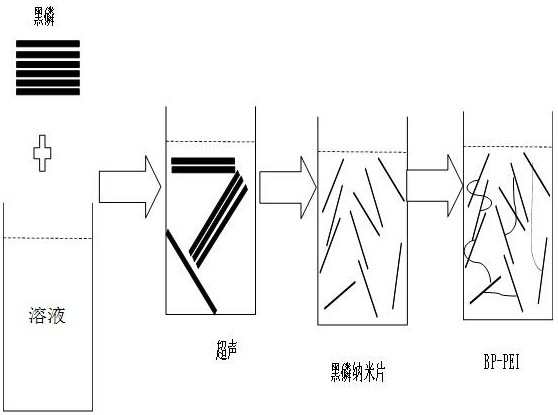

[0044] Step 3: Using single crystal black phosphorus as a raw material, use a simple liquid phase exfoliation method to peel it into two-dimensional thin-layer black phosphorus single layer and multi-layer micro-nano sheets with a thickness of 1-20 nm;

[0045] The ultrasonic energy generated by the cell ultrasonic breaker is used to peel off the si...

Embodiment 1

[0075] S1: A silicon-doped n-GaN epitaxial wafer was epitaxially grown on a four-inch sapphire substrate by metal-organic chemical vapor deposition (MOCVD). The thickness of the gallium nitride layer was 35 nm, and the silicon doping concentration was 1×10 18 cm -3 -9×10 18 cm -3 .

[0076] S2: Depositing 30nm SiO on the surface of GaN epiwafer by PECVD 2 After removing the photoresist, place a mask plate, use a series of processes such as exposure and development to prepare an in-situ mask plate, and use magnetron sputtering technology to deposit Ti / Al / Pt / Au electrodes on GaN epitaxial wafers, so that It forms an ohmic contact with the GaN epiwafer for good electrical performance. Afterwards, split the GaN epitaxial wafers on which the electrodes have been prepared, so that the four-inch GaN epitaxial wafers are evenly divided into 5 mm×5 mm epitaxial wafers.

[0077] S3: Using single crystal black phosphorus as raw material, it is exfoliated into a 1-20 nm thick two-dim...

Embodiment 2

[0082] S1: An n-type gallium nitride layer was epitaxially grown on a sapphire substrate by metal-organic chemical vapor deposition. The thickness of the gallium nitride layer was 35 nm, and the silicon doping concentration was 1×10 18 cm −3 - 9×10 18 cm −3 .

[0083] S2: Depositing 30nm SiO on the surface of GaN epiwafer by PECVD 2 Layer, place the mask plate after throwing the photoresist, exposure, development and other processes to prepare the in-situ mask plate, and use the magnetron sputtering technology to deposit Ti / Al / Pt / Au electrodes on the gallium nitride epitaxial wafer to make it Form ohmic contact with GaN epiwafer for good electrical performance. Afterwards, split the GaN epitaxial wafers on which the electrodes have been prepared, so that the four-inch GaN epitaxial wafers are evenly divided into 5 mm×5 mm epitaxial wafers.

[0084] S3: Exfoliate the black phosphorus flakes from the bulk black phosphorus in the liquid phase, first use a mortar to grind the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com