Surface-mounted solid aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor, surface mount technology, used in solid electrolytic capacitors, electrolytic capacitors, capacitor manufacturing and other directions, can solve problems such as position offset, capacitor failure, core package mechanical impact, etc., to improve moisture resistance, reduce impact, The effect of preventing delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] A method for preparing a surface-mounted solid aluminum electrolytic capacitor, comprising the following steps:

[0056] S1: cutting the chemically formed aluminum foil to form the first aluminum foil;

[0057] S2: Coating insulating glue on the surface of the first aluminum foil, dividing the anode area and the cathode area, and forming the second aluminum foil;

[0058] S3: Rechemically repairing the dielectric layer on the side of the cathode region of the second aluminum foil to form a third aluminum foil;

[0059] S4: forming a conductive polymer electrolyte layer on the surface of the cathode region of the third aluminum foil to form a fourth aluminum foil;

[0060] S5: Conducting conductive paste on the surface of the fourth aluminum foil cathode region to form a monolithic core 1;

[0061] S6: Connect several cores 1 with the external three-dimensional lead frame 2 to form a capacitor core package 3;

[0062] S7: Encapsulating and aging the capacitor core pac...

Embodiment 1

[0065] Please refer to Figure 1-6 , Embodiment 1 of the present invention is:

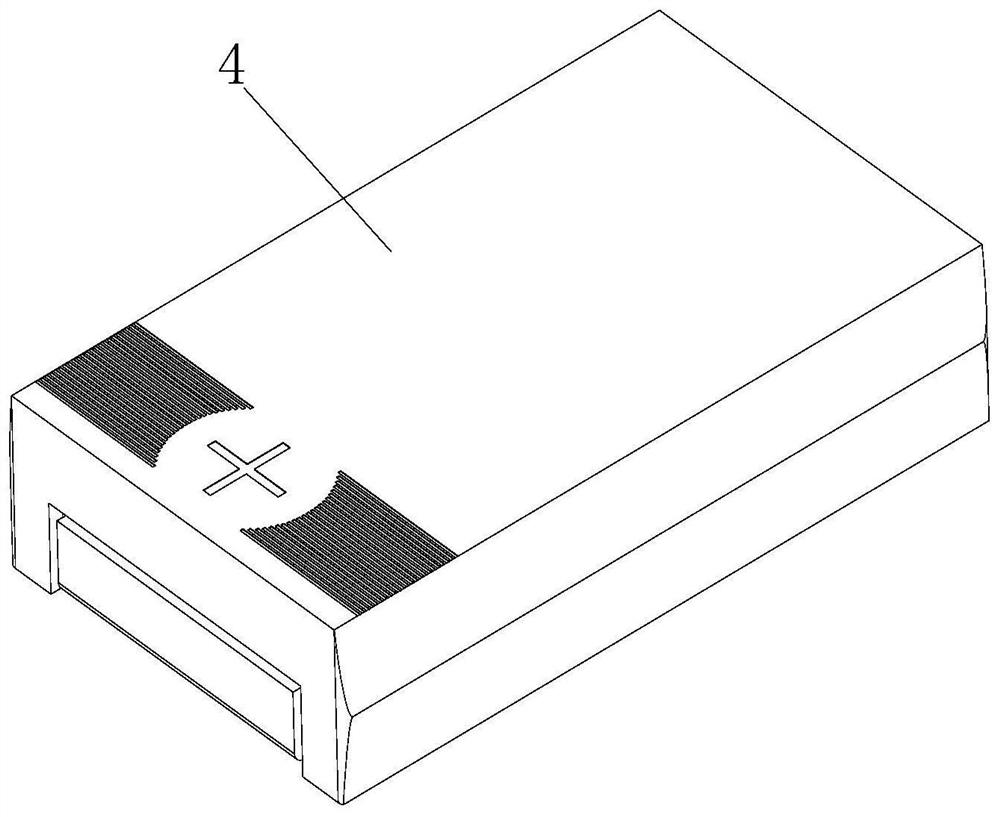

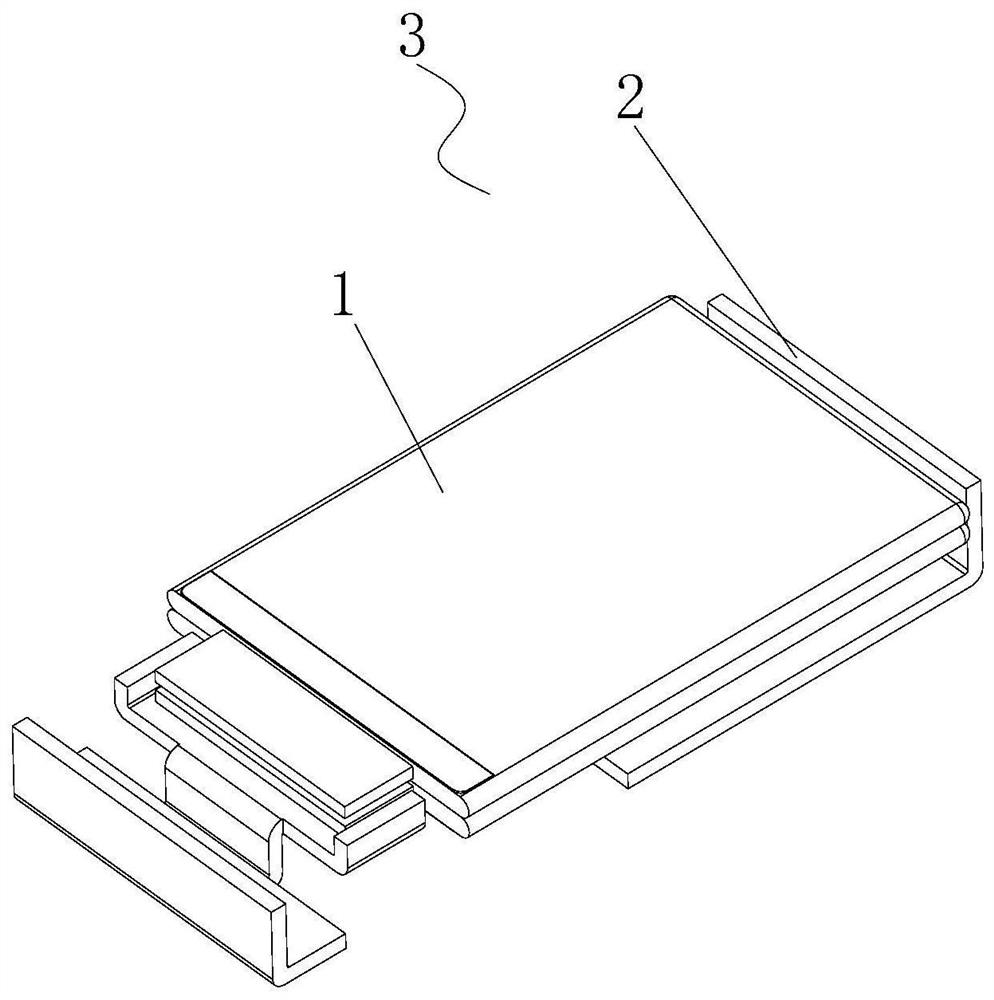

[0066] A surface-mounted solid aluminum electrolytic capacitor, comprising several stacked cores 1 and three-dimensional lead frames 2, several cores 1 are mounted on the three-dimensional lead frame 2, and a capacitor is formed between the cores 1 and the three-dimensional lead frame 2 The core package 3, the capacitor core package 3 is packaged and aged to obtain the capacitor 4;

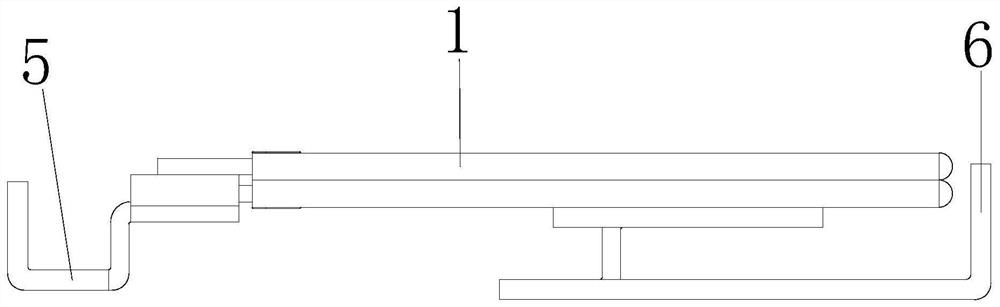

[0067] The three-dimensional lead frame 2 includes an anode metal frame 5 and a cathode metal frame 6 that cooperate with each other, the anode metal frame 5 is connected to the anode of the core 1, the cathode metal frame 6 is connected to the cathode of the core 1, and the anode of the core 1 It is connected with the anode tongue 53 provided on the anode metal frame 5 by welding, the cathode of the core 1 is connected with the cathode tongue 63 provided on the cathode metal frame 6, and the cathode of the core 1 an...

Embodiment 2

[0082] The difference with embodiment 1 is:

[0083] The width of the anode end 51 is 50% of the total width of the capacitor 4, the length of the horizontal portion of the anode end 51 is 12% of the total length of the capacitor 4, and the height of the vertical portion of the anode end 51 is 50% of the total height of the capacitor 4. The height of the connecting portion 52 is 10% of the total height of the capacitor 4;

[0084] The length of the horizontal portion of the cathode end portion 61 is 33% of the total length of the capacitor 4, the height of the vertical portion of the cathode end portion 61 is 50% of the total height of the capacitor 4, and the length of the cathode tongue portion 63 is 50% of the length of the horizontal portion of the cathode end portion 61. %, the width of the cathode tongue 63 is 33% of the width of the horizontal part of the cathode end 61, and the width of the cathode connecting portion 62 is 33% of the width of the cathode tongue 63;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com