Castable for insulating tube bus and process for preparing inorganic insulating tube bus by using same

A technology for insulating pipes and castables is applied in the field of insulating pipe busbar castables and the technical field of preparing inorganic insulating pipe busbars. The effect of good and super corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

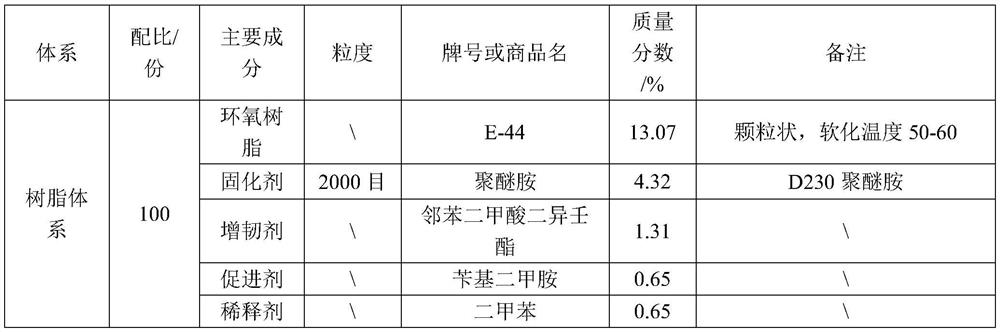

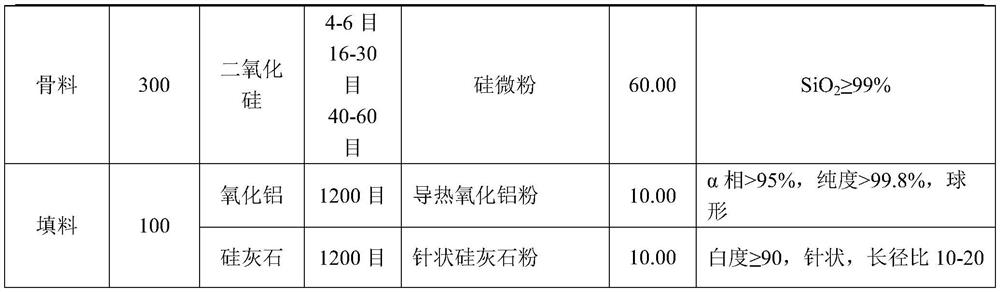

[0030] An insulating tube busbar castable, the mass fraction and specifications of its raw materials are shown in Table 2.

[0031] Table 2 Raw material mix ratio of insulating pipe busbar castable

[0032]

[0033]

[0034] The process of preparing the insulating pipe busbar using the insulating pipe busbar castable described in this embodiment, according to the ratio and specifications of the raw materials described in Table 2, the specific preparation method includes the following steps in sequence:

[0035] (1) Aggregate silicon micropowder and filler (silicon oxide and wollastonite) are placed in a drying oven to dry for subsequent use;

[0036] (2) Add the epoxy resin to the mixer, heat up to 120°C, stir evenly after it is completely melted, add the dried and cooled filler (silicon oxide and wollastonite), cool down to 85°C, and vacuum degas;

[0037] (3) Add aggregate silicon micropowder (4-6 mesh, 16-30 mesh and 40-60 mesh gradation 6:1:1), curing agent (polyeth...

Embodiment 2

[0041] The difference between Example 2 and Example 1 is that the aggregate silica powder is composed of particle sizes of 4-6 mesh, 16-30 mesh and 40-60 mesh in a gradation of 4:3:1.

[0042]Combined with the performance test results in Table 3, it shows that the insulating pipe busbar prepared by the insulating pipe busbar castable described in Example 2 has a smooth appearance without delamination, and the mechanical test results show that the flexural strength is 35MPa, and has good mechanical properties; the water absorption rate is tested 0.03%, with excellent waterproof effect; electrical performance test results show that the insulation resistance at room temperature is 13000MΩ, with excellent insulation effect; fire resistance test low voltage 760° / 3h fire prevention.

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is that the parts of resin system, aggregate and filler are 150 parts, 650 parts and 200 parts respectively.

[0045] Combined with the performance test results in Table 3, it is shown that the insulating pipe busbar prepared by the insulating pipe busbar castable described in Example 3 is not smooth and not delaminated. The mechanical test results show that the flexural strength is 31MPa and has excellent mechanical properties; the water absorption rate is tested 0.05%, with excellent waterproof effect; electrical performance test results show that the insulation resistance at room temperature is 10000MΩ, with excellent insulation effect; fire resistance test low voltage 750° / 3h fire prevention.

[0046] Table 3 main properties of the insulating castable of the present invention

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com