Alloying and heat treatment method for improving plasticity of cast aluminum-copper alloy at room temperature

A heat treatment method and technology for aluminum-copper alloys are applied in the field of alloying and heat treatment to improve the room temperature plasticity of cast aluminum-copper alloys, which can solve the problem that the room temperature plasticity cannot meet the requirements of orthopedic treatment, and ensure the manufacturability and high-temperature service safety. Good room temperature plasticity and the effect of increasing the free path of dislocation motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

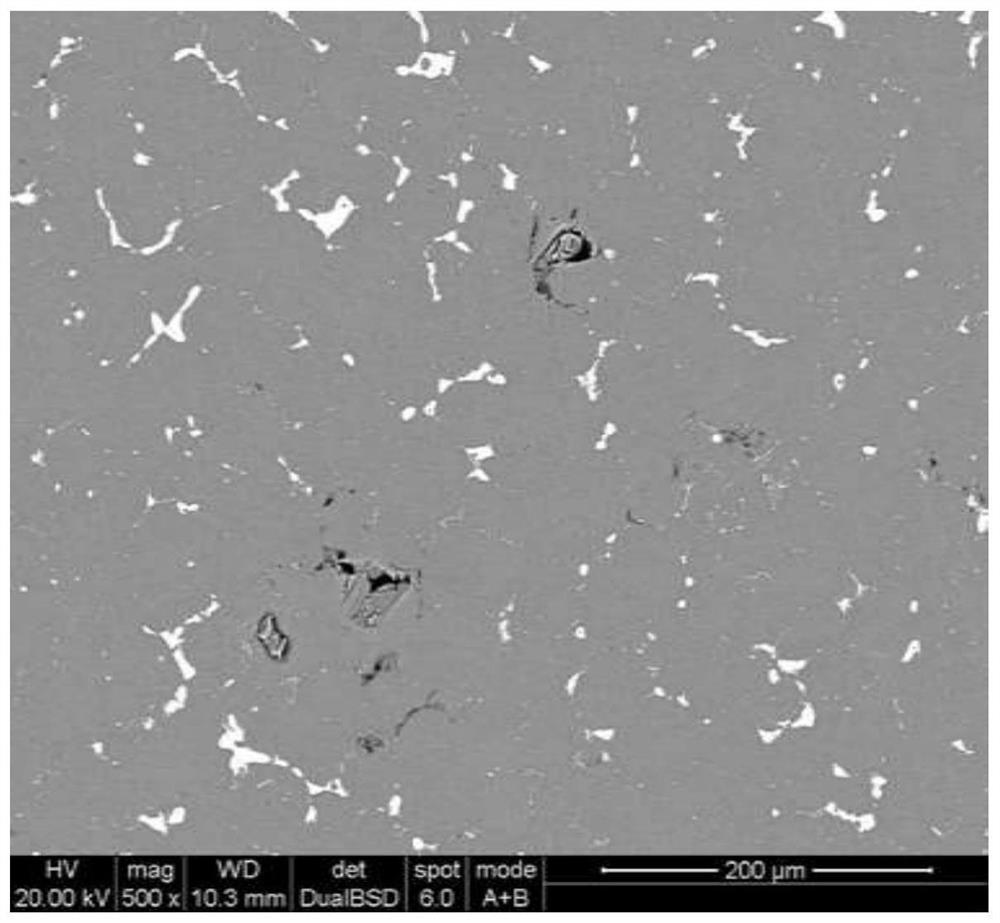

Embodiment 1

[0036] The alloy composition is: 7.50% Cu, 0.26% Mg, 1.30% Ag, 0.35% Mn, 0.25% Ti, 0.25% V, 0.25% Cd, 0.05% Ce, 0.003% Be, 0.02% Fe, 0.02% Si, the balance Al, and the sum of each component is 100%.

[0037] The alloy is firstly subjected to solution heat treatment at 520°C / 16h, then subjected to natural aging for 18h, and finally artificially aged at 160°C / 13h. The room temperature and high temperature tensile properties of the alloy are shown in Table 1.

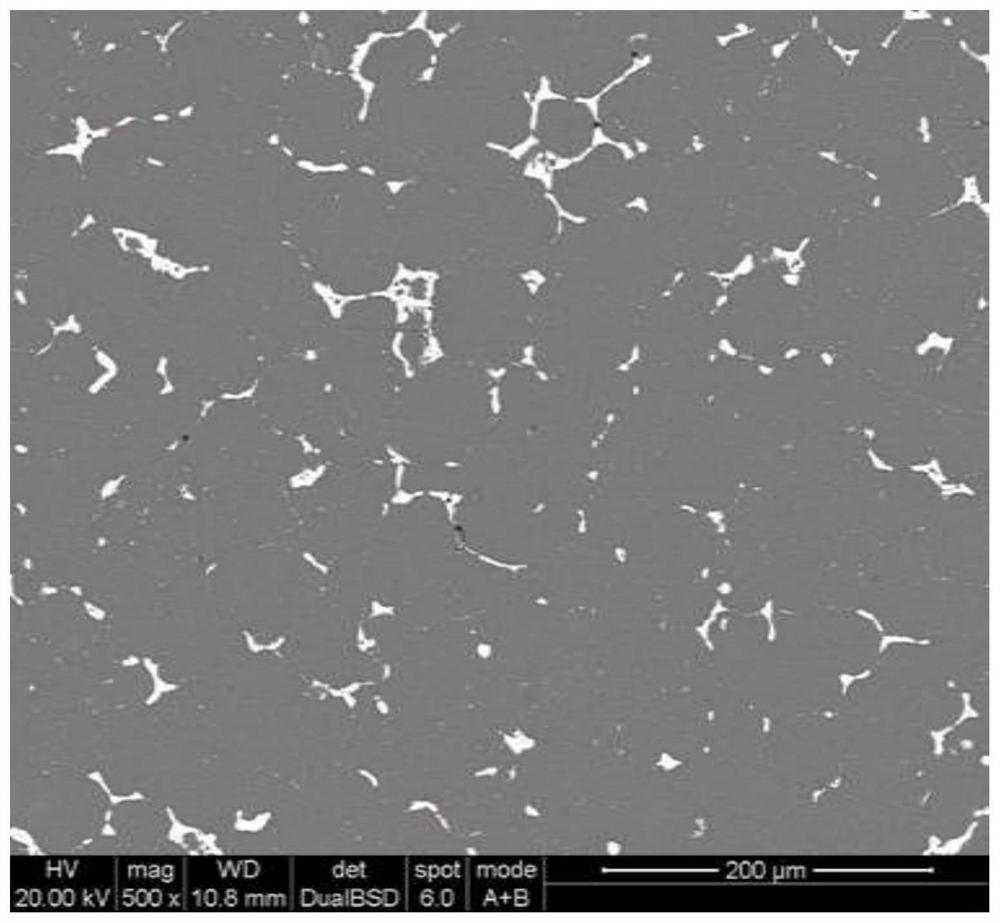

Embodiment 2

[0039] The alloy composition is: 7.0% Cu, 0.18% Mg, 1.20% Ag, 0.45% Mn, 0.20% Ti, 0.18% V, 0.15% Cd, 0.05% Ce, 0.003% Be, 0.04% Fe, 0.05% Si, the balance Al, and the sum of each component is 100%.

[0040] The alloy is firstly subjected to solution heat treatment at 490°C / 24h, then to natural aging for 4h, and finally to artificial aging heat treatment at 185°C / 8h. The room temperature and high temperature tensile properties of the alloy are shown in Table 1.

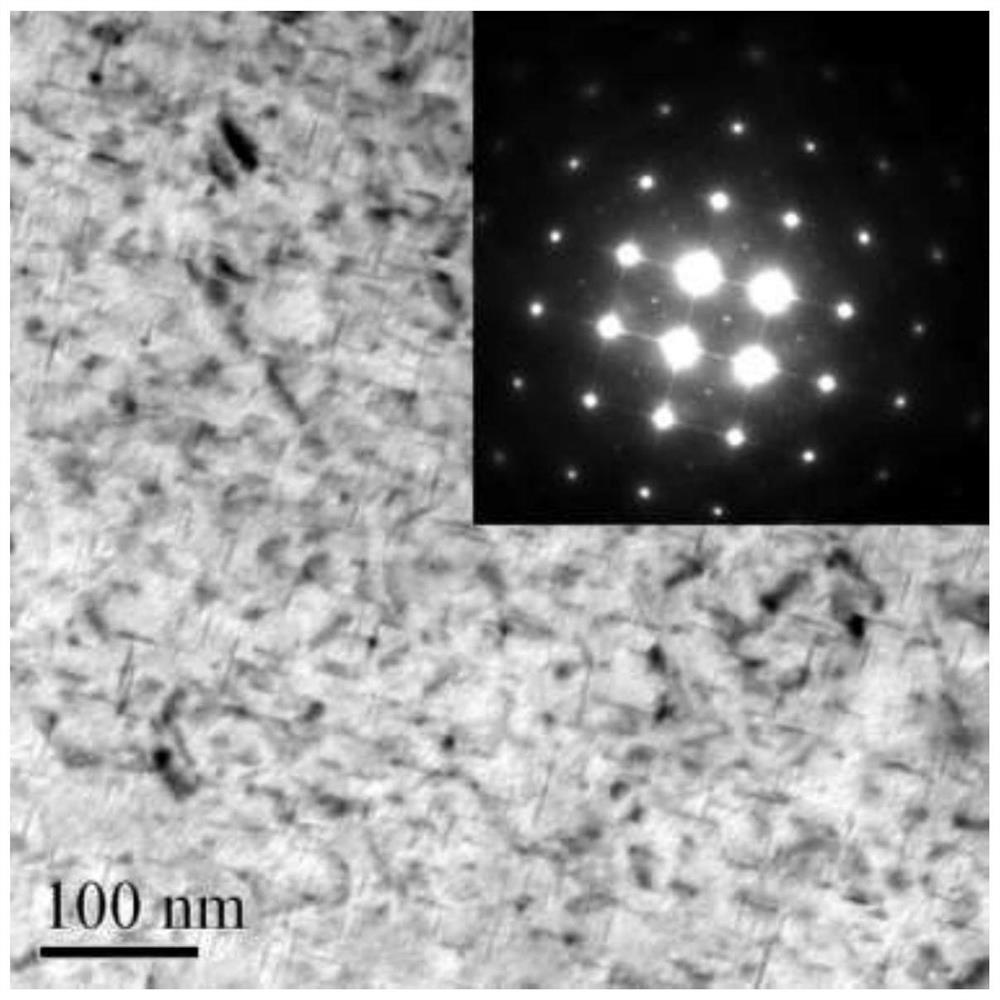

Embodiment 3

[0042] The alloy composition is: 6.90% Cu, 0.14% Mg, 1.00% Ag, 0.30% Mn, 0.15% Ti, 0.15% V, 0.15% Cd, 0.05% Ce, 0.003% Be, 0.02% Fe, 0.02% Si, the balance Al, and the sum of each component is 100%.

[0043] The alloy is firstly subjected to solution heat treatment at 540°C / 8h, then to natural aging for 24h, and finally to artificial aging heat treatment at 190°C / 5h. The room temperature and high temperature tensile properties of the alloy are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com