Landfill leachate membrane concentrated solution treatment process and system

A technology for landfill leachate and treatment process, applied in the field of landfill leachate application, can solve the problems of reducing heat exchange efficiency and evaporation energy efficiency ratio, reducing operation stability, equipment fouling, etc., achieving long maintenance period, reducing energy consumption, The effect of not easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

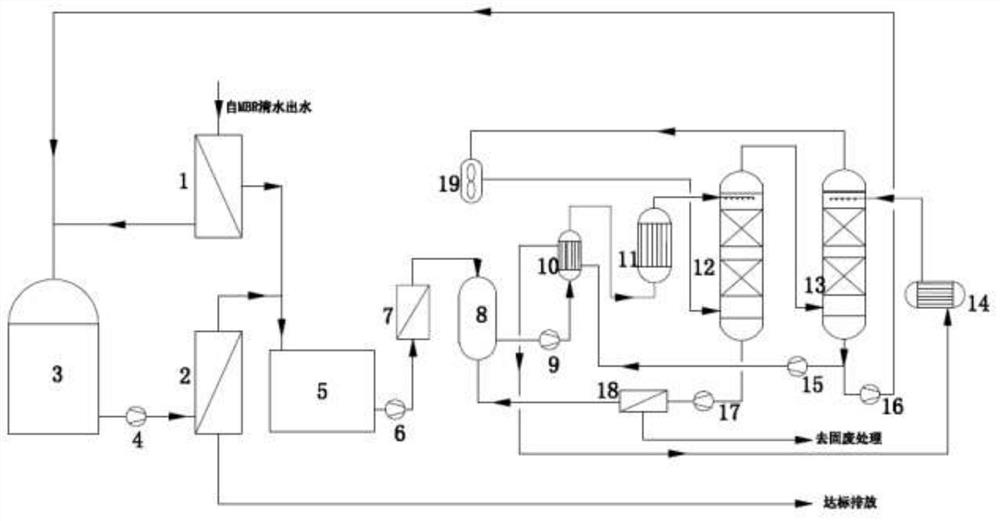

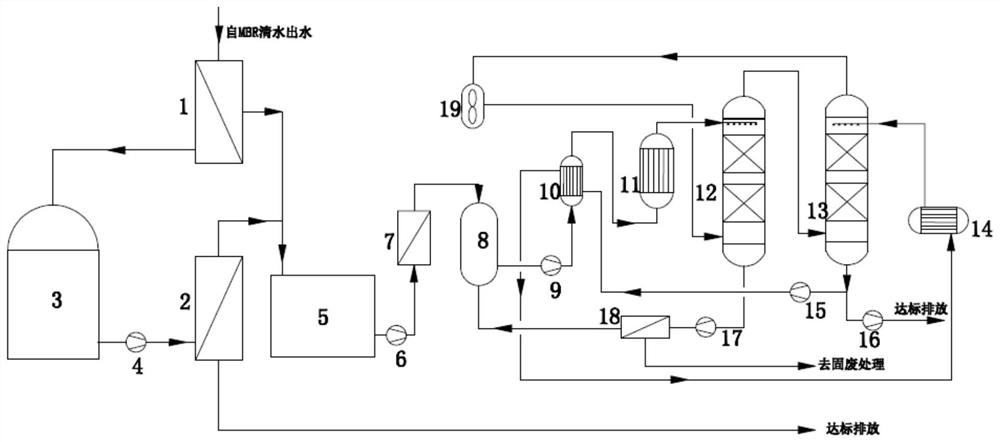

[0026] A treatment process for landfill leachate membrane concentrate, such as figure 2 As shown, the process includes the following steps: the concentrated liquid mother liquor from the nanofiltration system 1 and the reverse osmosis system 2 in the garbage permeate membrane treatment process, the treatment capacity is about 1000kg / h, and its main water quality index: COD about 5000mg / h L, conductivity is 40mS / cm, TDS is 10000mg / L. The mother liquor passes through the mortar pump 6 and the automatic backwash filter 7 to remove some large particles of solid impurities and then enters the mother liquor buffer tank 8, is pressed into the preheater 10 by the mother liquor pump, preheats the temperature to 48°C, and then enters the heater 11. The outlet temperature of the mother liquor was raised to 60°C. The mother liquor enters from the top of the evaporator 12 by spraying, and directly contacts with the air from bottom to top, where the air is provided by the fan 19, and the ...

Embodiment 2

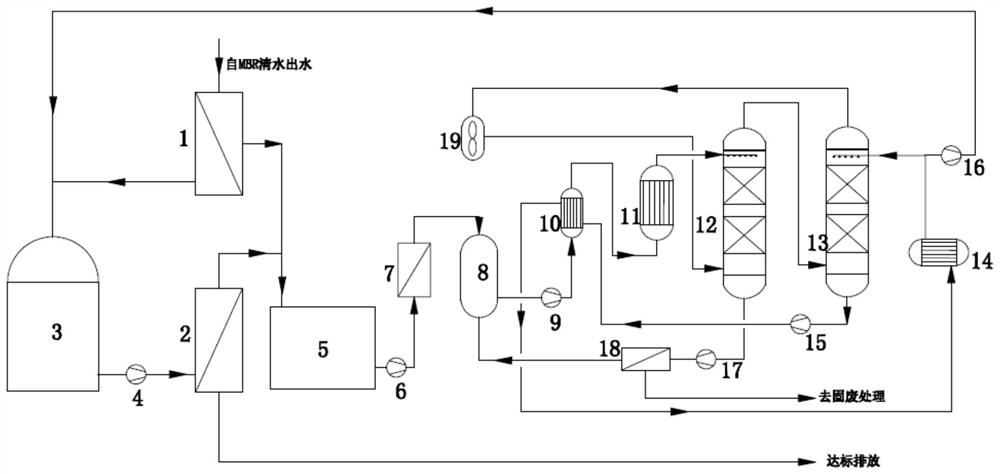

[0028]A treatment process for landfill leachate membrane concentrate, such as image 3 As shown, the process includes the following steps: the concentrated liquid mother liquor from the nanofiltration system 1 and the reverse osmosis system 2 in the garbage permeate membrane treatment process has a treatment capacity of about 1500kg / h, and its main water quality index: COD about 10000mg / h L, conductivity is 50mS / cm, TDS is 16000mg / L. The mother liquor passes through the mortar pump 6 and the plate-and-frame filter press 7 to remove some large particles of solid impurities and then enters the mother liquor buffer tank 8, and is pressed into the preheater 10 by the mother liquor pump to preheat the temperature to 60°C, and then enters the heater 11 , so that the outlet temperature of the mother liquor rose to 80 ° C. The mother liquid enters from the top of the evaporator 12 by spraying, and directly contacts with the air from bottom to top, where the air is provided by the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com