Solid electrolyte, preparation method thereof and lithium ion battery

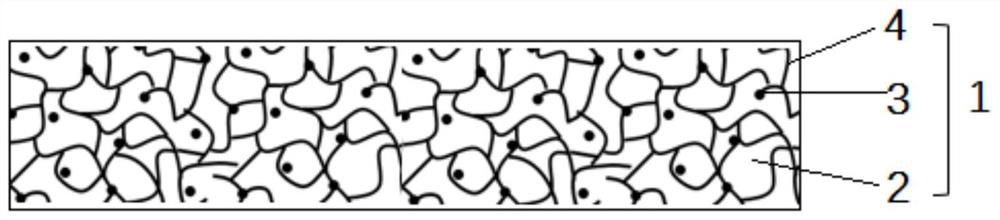

A solid electrolyte and electrolyte technology, applied in the field of electrolytes, can solve problems such as large grain boundary resistance, Li salt volatilization, and limited improvement effect, and achieve the effect of improving interface performance, reducing grain boundary resistance, and smooth ion conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Will Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3Electrolyte powder, ammonium carbonate and lithium chloride are mixed thoroughly according to the mass ratio of 8:0.2:0.5 and ball milled evenly, the ball milling speed is 500rpm, and the ball milling time is 3h; the mixture powder is pressed into flakes, and sintered at 850°C for 5h After cooling, the electrolyte precursor is obtained;

[0059] (2) Polyethylene oxide and LiTFSI were dissolved in acetonitrile according to a mass ratio of 9:4, and fully stirred to obtain a polymer electrolyte slurry; the electrolyte precursor was soaked in the polymer electrolyte slurry for 30 minutes, and dried at room temperature; 60 The solvent was removed by vacuum drying at ℃ to obtain a solid electrolyte, wherein the mass ratio of the electrolyte precursor to the polymer electrolyte was 8.5:1.

[0060] (3) Using the lamination process, the positive electrode sheet, the above-mentioned solid electrolyte and the negative electrode sheet are...

Embodiment 2

[0065] (1) Will Li 3 OCl electrolyte powder, PMMA microspheres and lithium oxide are fully mixed according to the mass ratio of 6.4:0.3:0.6 and ball milled evenly, the ball milling speed is 150rpm, and the ball milling time is 2h; the mixture powder is pressed into flakes and sintered at 800°C 3h cooling to obtain the electrolyte precursor;

[0066] (2) Combine styrene-butadiene rubber with LiPF 6 Dissolve in chloroform according to the mass ratio of 5.3:1.4, and fully stir to obtain a polymer electrolyte slurry; soak the electrolyte precursor in the polymer electrolyte slurry for 50 minutes, and dry at room temperature; vacuum dry at room temperature to remove the solvent to obtain a solid electrolyte, the SEM image of the surface of the solid electrolyte is shown in Figure 4 . Wherein, the mass ratio of the electrolyte precursor to the polymer electrolyte is 7:1;

[0067] (3) The positive electrode sheet, the above-mentioned solid electrolyte and the negative electrode ...

Embodiment 3

[0072] (1) Will Li 6.6 La 3 Zr 1.6 Ta 0.4 o 12 Electrolyte powder, ammonium bicarbonate and lithium phosphate are fully mixed according to the mass ratio of 7.4:0.2:0.7 and ball milled evenly, the ball milling speed is 400rpm, and the ball milling time is 12h; the mixture powder is pressed into flakes, and sintered at 900°C for 6h cooling to obtain the electrolyte precursor;

[0073] (2) Polyethylene glycol, LiBOB and plasticizer are dissolved in acetone according to the mass ratio of 3:1:1, and fully stirred to obtain the polymer electrolyte slurry; the electrolyte precursor is mixed in the polymer electrolyte slurry Soak for 15min, dry at room temperature; remove the solvent by vacuum drying at room temperature to obtain a solid electrolyte, the AC impedance diagram of the solid electrolyte is shown in Figure 5 . Wherein, the mass ratio of the electrolyte precursor to the polymer electrolyte is 8.1:1;

[0074] (3) The positive electrode sheet, the above-mentioned sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com