Method for preparing bifunctional ternary metal hydroxynitride electrocatalyst by using waste lithium cobalt oxide

A ternary metal and nitride electrolytic technology, which is applied in the field of waste resource utilization and catalytic chemistry, can solve the problems of waste of useful resources, increase of disposal costs, inability to realize recycling and value-added of waste materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

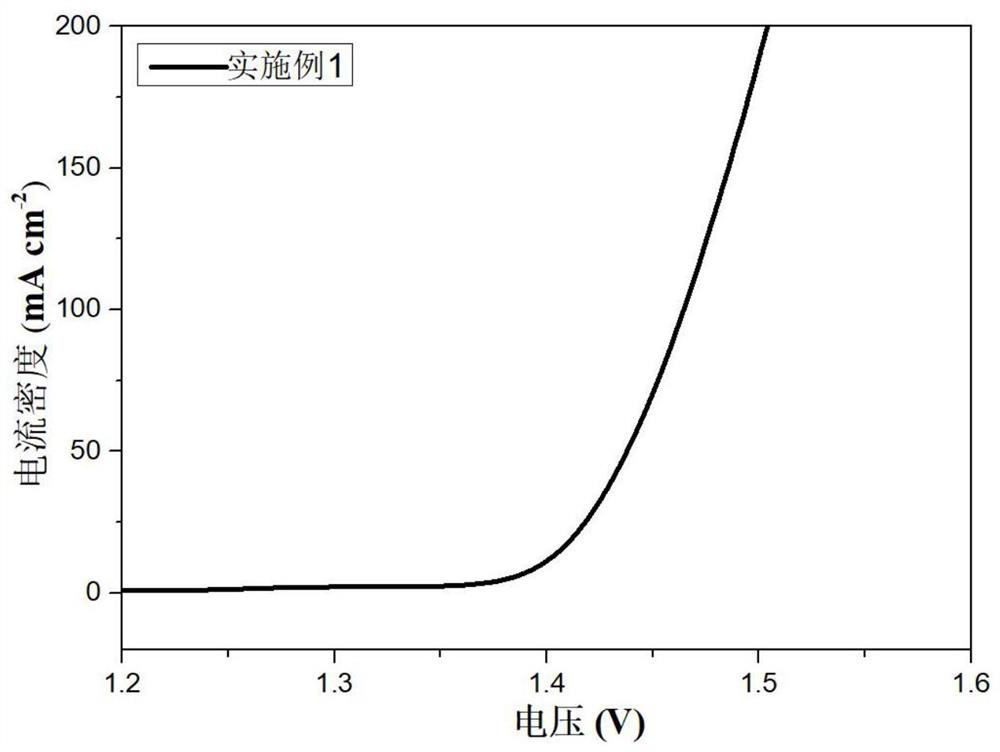

Embodiment 1

[0044] A method for preparing a bifunctional ternary metal oxynitride electrocatalyst by using waste lithium cobaltate is carried out in sequence according to the following steps:

[0045] (11) Sieve the lithium cobalt oxide positive electrode material recovered from the waste lithium-ion battery after crushing, take the undersieve, grind the undersieve into powder, pass through a 400-mesh sieve, soak in 3M dilute hydrochloric acid for 5 hours, and take The supernatant is marked as A;

[0046] (12) Add a certain amount of sodium hydroxide solution to A until the pH value of the solution is 7 to obtain B;

[0047] (13) Add 100mM ferric nitrate solution and 5mL of ethanol to B in sequence to obtain C;

[0048] (14) Put aluminum foam with a diameter of 1cm×1cm (thickness 0.01cm) into C, use aluminum foam as the working electrode, and use C as the reaction solution, soak the foamed aluminum on the surface of the C solution, and treat it under a nitrogen atmosphere at the same tim...

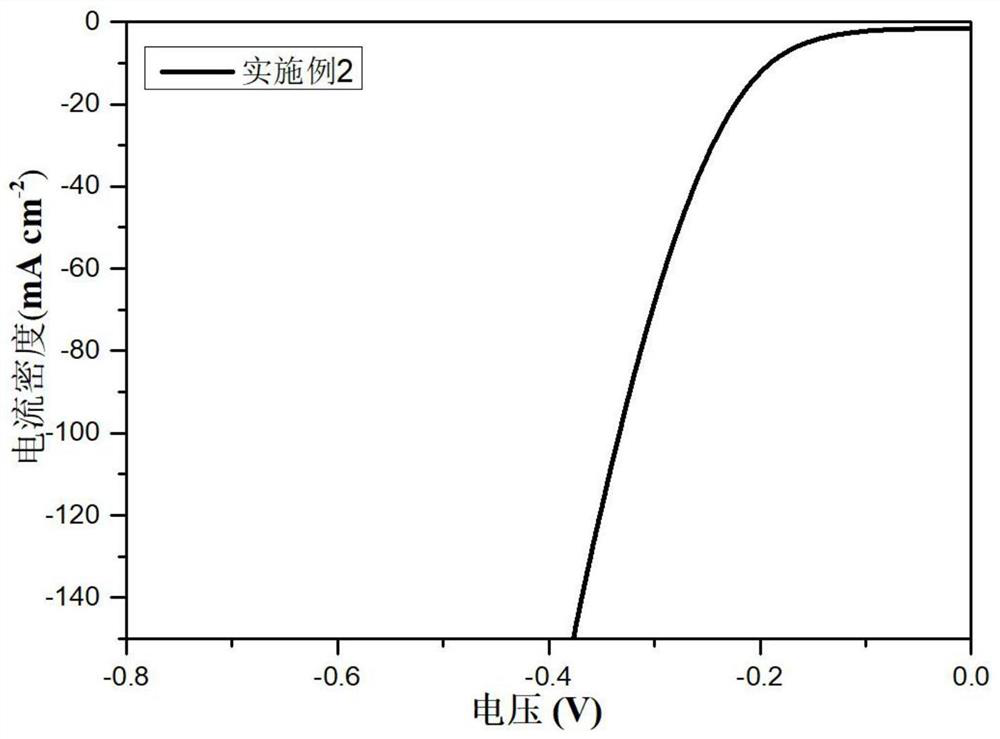

Embodiment 2

[0052] A method for preparing a bifunctional ternary metal oxynitride electrocatalyst by using waste lithium cobaltate is carried out in sequence according to the following steps:

[0053] (21) Sieve the waste lithium cobaltate cathode material after crushing, take the undersieve, grind the undersieve into powder, pass through a 400 mesh sieve, soak in 6M dilute hydrochloric acid for 3 hours, take the supernatant and record it as A ;

[0054] (22) Add a certain amount of sodium hydroxide solution to A until the pH value of the solution is 7 to obtain B;

[0055] (23) Add 150mM ferric nitrate solution and 8mL of ethanol to B in sequence to obtain C;

[0056] (24) Put aluminum foam (thickness 0.01cm) with a diameter of 1cm×1cm into C, use aluminum foam as the working electrode, and use C as the reaction solution, soak the foamed aluminum on the surface of the C solution, and treat the Aluminum foam is subjected to plasma discharge at a voltage of 50V for 120s, so that electroc...

Embodiment 3

[0060] A method for preparing a bifunctional ternary metal oxynitride electrocatalyst by using waste lithium cobaltate is carried out in sequence according to the following steps:

[0061] (31) Sieve the waste lithium cobaltate positive electrode material after crushing, take the undersieve, grind the undersieve into powder, pass through a 400 mesh sieve, soak in 5M dilute hydrochloric acid for 8 hours, take the supernatant and record it as A ;

[0062] (32) Add a certain amount of sodium hydroxide solution to A until the pH value of the solution is 7 to obtain B;

[0063] (33) Add 110mM ferric nitrate solution and 10mL of ethanol to B in turn to get C;

[0064] (34) Put aluminum foam with a diameter of 1cm×1cm (thickness 0.01cm) into C, use aluminum foam as the working electrode, and use C as the reaction solution, soak the foamed aluminum on the surface of the C solution, and at the same time under nitrogen atmosphere Plasma discharge the aluminum foam at a voltage of 50V ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com