N-type copper-doped trimagnesium diantimonide alloy thermoelectric material and preparation method thereof

A thermoelectric material and copper doping technology, applied in the field of material science, can solve the problem of difficulty in individual regulation, and achieve the effect of improving thermoelectric performance, increasing electrical conductivity, and good thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

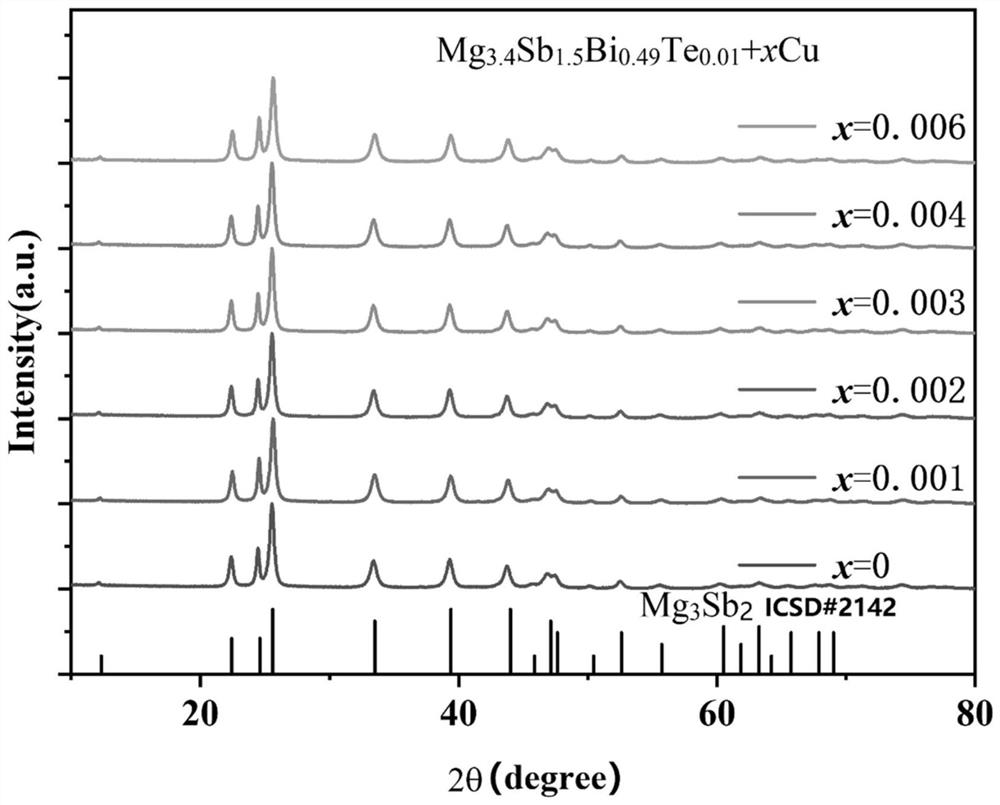

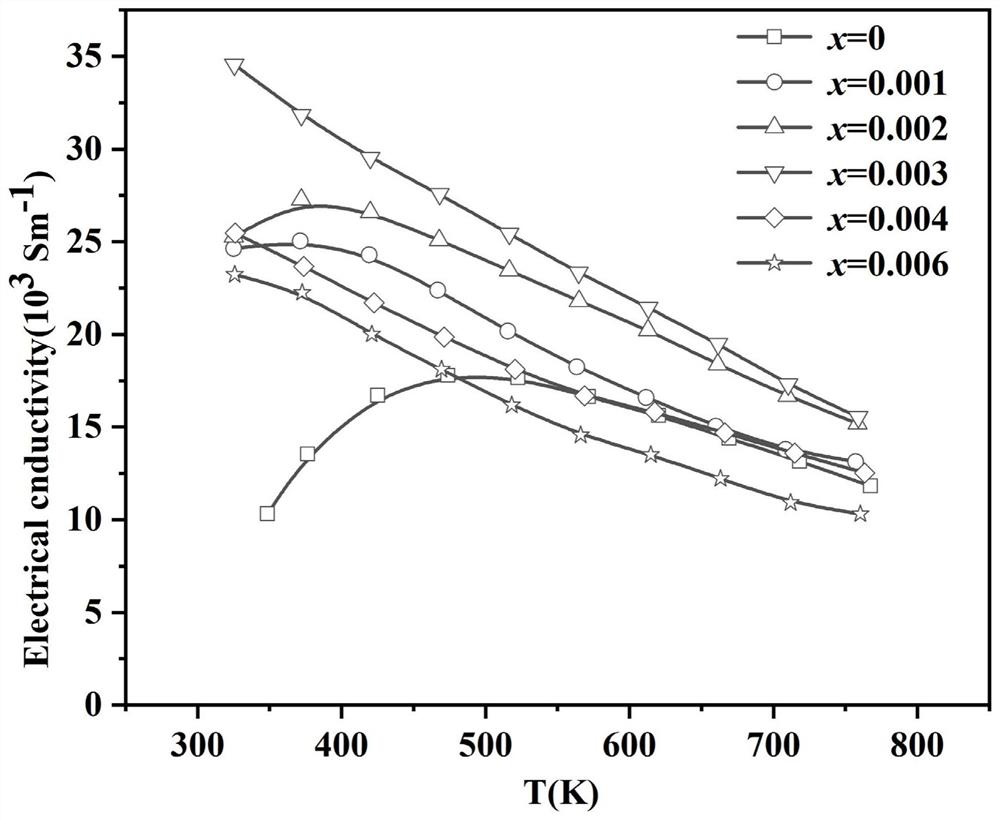

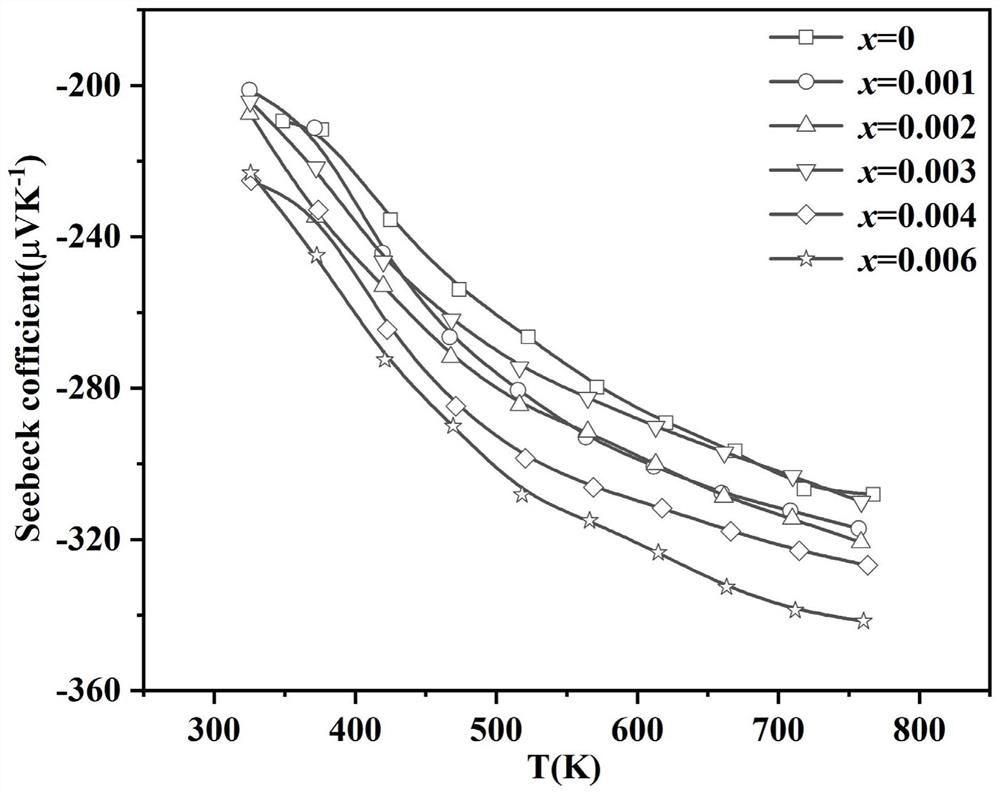

[0018] The invention provides an N-type copper-doped trismonide trimagnesium alloy thermoelectric material, and the general chemical formula of the thermoelectric material is: Mg 3.4 Sb 1.5 Bi 0.49 Te 0.01 +xCu, where x is the actual composition of the doping element Cu, and the range is 0.001≤x≤0.006. The present invention also provides a method for preparing an N-type copper-doped antimony trimagnesium alloy thermoelectric material, comprising the following steps:

[0019] a. In the inert atmosphere glove box, the Mg element, Sb element, Bi element, Te element element, and Cu element element will be weighed according to the stoichiometric ratio;

[0020] b. The reaction starter is put into a ball mill jar, and ball milled in a ball mill;

[0021] c. Taking out the product obtained in step b and performing plasma sintering to obtain an N-type copper-doped trimagnesium dismonide alloy thermoelectric material.

[0022] Wherein optionally, the ball milling speed in step b i...

Embodiment example 1

[0025] In this embodiment, an N-type antimony trimagnesium alloy thermoelectric material, its chemical formula is Mg 3.4 Sb 1.5 Bi 0.49 Te 0.01 .

[0026] The N-type diantimonide trimagnesium alloy thermoelectric material Mg used in this embodiment 3.4 Sb 1.5 Bi 0.49 Te 0.01 The preparation method comprises the following steps:

[0027] a. Preparation for ball milling of chemical elemental raw materials:

[0028] In a glove box filled with argon, weigh powdery elemental Mg (99.9%), powdery elemental Bi (99.99%), powdery elemental Sb (99.999%), and granular elemental Te (99.99%), according to 3.4: The molar ratio of 0.49:1.5:0.01 is put into the ball mill jar and sealed in the glove box;

[0029] b. Ball milling preparation process:

[0030] Put the ball mill jar into the ball mill and mill it at a speed of 550r / min for 72h, take out the reaction product in a glove box filled with argon, and grind it with a mortar;

[0031] c. Spark plasma sintering;

[0032] Place ...

Embodiment example 2

[0034] This experimental case is basically the same as the implementation case 1, and its special features are:

[0035] In this embodiment, the chemical formula of the N-type copper-doped trismonide trimagnesium alloy thermoelectric material is Mg 3.4 Sb 1.5 Bi 0.49 Te 0.01 +0.001Cu.

[0036] A kind of present embodiment N-type copper-doped antimonide trimagnesium alloy thermoelectric material Mg 3.4 Sb 1.5 Bi 0.49 Te 0.01 The preparation method of +0.001Cu comprises the following steps:

[0037] a. Preparation for ball milling of chemical elemental raw materials:

[0038] According to the chemical formula Mg of the prepared target thermoelectric material 3.4 Sb 1.5 Bi 0.49 Te 0.01 +0.001Cu, add and weigh powdery elemental Mg (99.9%), powdery elemental Bi (99.99%), powdery elemental Sb (99.999%), granular elemental Te (99.99%), according to 3.4:0.49:1.5: With a molar ratio of 0.01, the powdered elemental Cu (99.99%) with a mass percentage of 0.001 was weighed and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com