Five-axis silica gel 3D printer and printing method thereof

A 3D printer and silica gel technology, applied in the direction of 3D object support structures, manufacturing tools, coating devices, etc., can solve the problems of high difficulty in printing workpieces and long printing time, so as to reduce printing difficulty, reduce printing time, and solve printing problems. long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

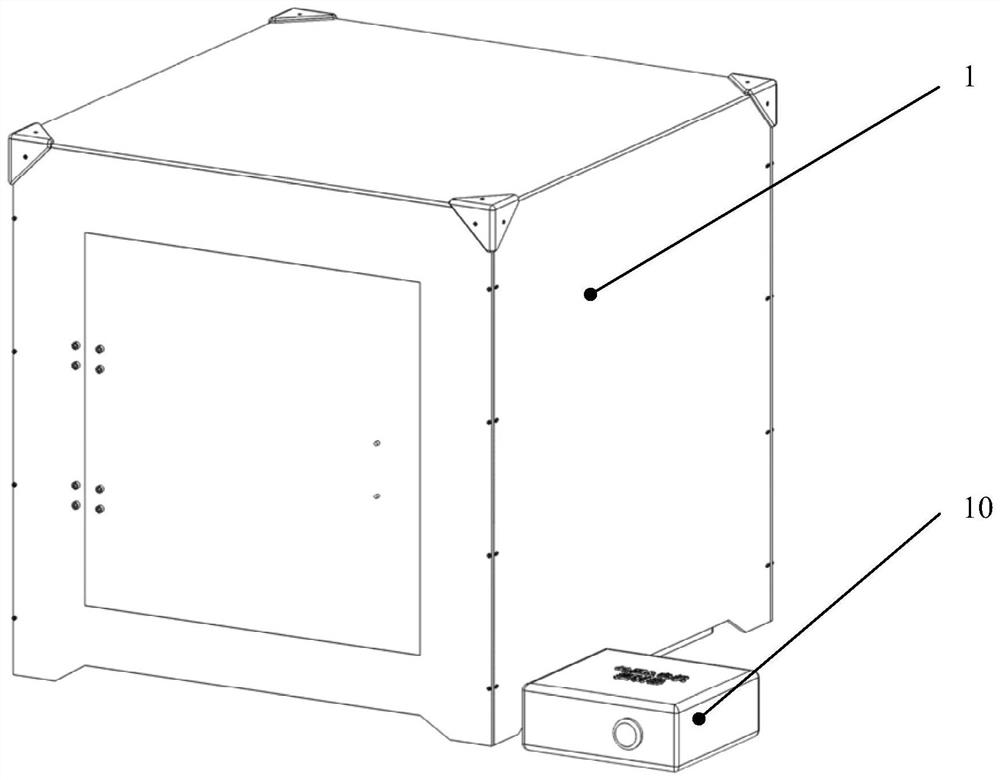

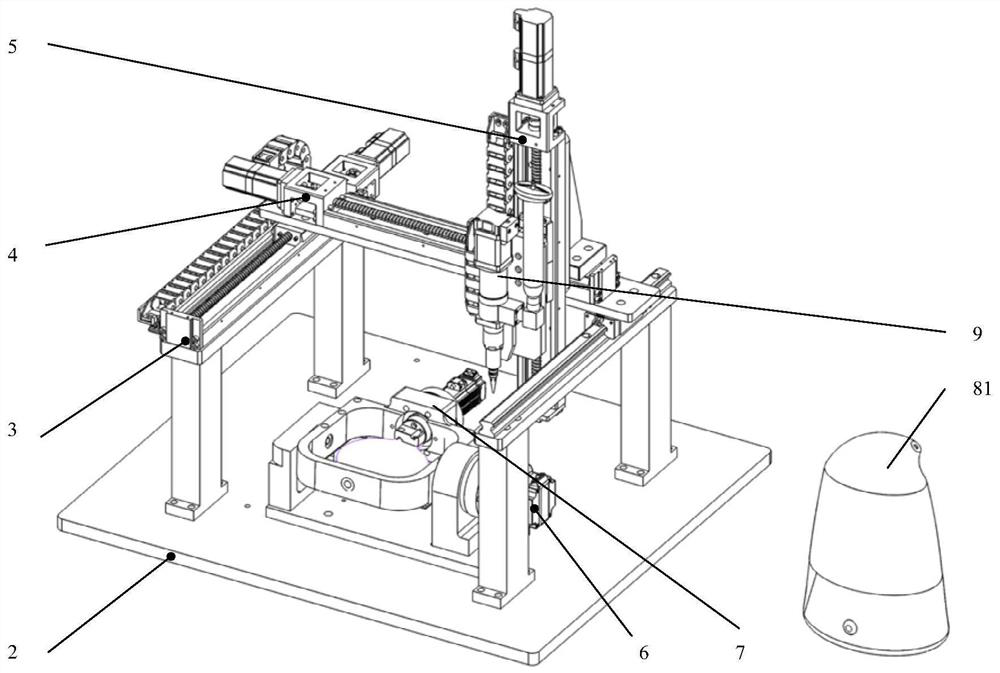

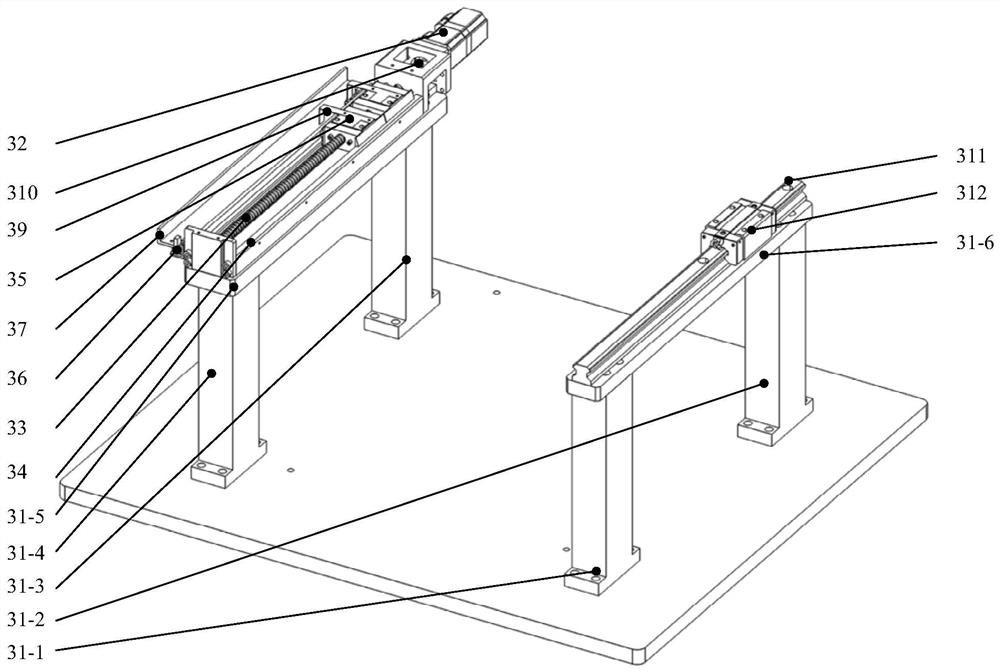

[0051] see Figure 1-9, the present embodiment provides a five-axis silicone 3D printer, which is used to print materials in the workpiece coordinate system according to the required extrusion axis vector and position to obtain a three-dimensional product. In this embodiment, the printing material is a flexible material, which may be a moisture-curing / room-temperature-curing material. The printing material is specifically a single-component silicone material, which is cured and characterized by moisture curing / heat curing, which can realize rapid prototyping of products and realize five-axis 3D printing of silicone products. Wherein, the 3D printer includes a housing 1, a base 2, an extrusion device 9, a three-axis motion platform, a two-axis motion platform, an auxiliary device 8 and a control system 10. Among them, the three-axis motion platform and the two-axis motion platform together form a five-axis motion system (platform).

[0052] In this embodiment, the housing 1 i...

Embodiment 2

[0078]This embodiment provides a five-axis silicone 3D printer, which determines the printing material on the basis of Embodiment 1. In this embodiment, the material used is a silicone rubber material, which is a one-component silicone rubber, hereinafter referred to as silica gel. Silica gel is a colloidal, long-chain silicone polymer containing 6000-7000 silicon-oxygen units. There is partially cross-linked silica gel in this polymer. Silicone rubber has good temperature resistance (-65~ 177℃), corrosion resistance and good insulation. The characteristic of silica gel is that it is cured by condensation reaction, cross-linking and polymerization. This reaction requires the participation of water, and releases oxime compounds, alcohol or acetic acid according to different materials. Here, one-component deoximation cured silica gel is taken as an example. In a humid environment, silica gel has the characteristics of quick drying on the surface, skinning in 3 to 6 minutes, sur...

Embodiment 3

[0080] This embodiment provides a five-axis silicone 3D printer, which is similar to Embodiment 1, except that the detection system and the adjustment system are different. Wherein, the detection system includes a temperature detection device and a humidity detection device. In this embodiment, the humidity detection device includes a humidity sensor. The humidity sensor is installed in the housing 1 and is used to detect real-time humidity. A temperature sensor is installed in the housing 1 and used to detect real-time temperature. In order to facilitate the detection of temperature and humidity, the two can also be directly assembled together, and a suitable temperature and humidity sensor is selected to detect the temperature and humidity.

[0081] The temperature regulating device includes a semiconductor cooling sheet (hereinafter referred to as a cooling sheet) and a resistance heating network (hereinafter referred to as a heating network). The cold chip is installed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com