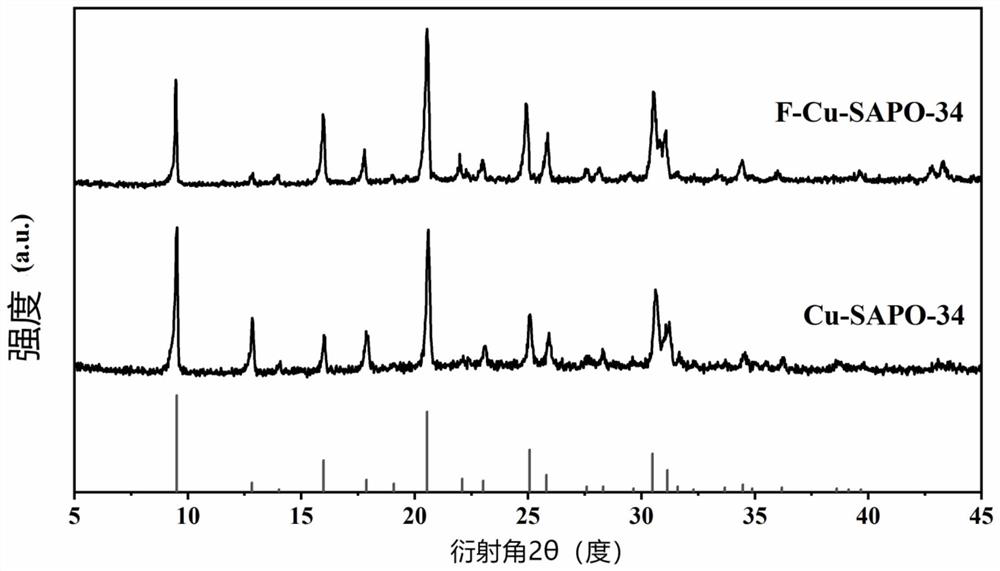

Novel efficient denitration catalyst as well as preparation method and application thereof

A denitrification catalyst, high-efficiency technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high preparation cost, narrow activity temperature window, and insufficient low-temperature activity, and achieve enhanced low-temperature activity and operation The effect of convenience and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

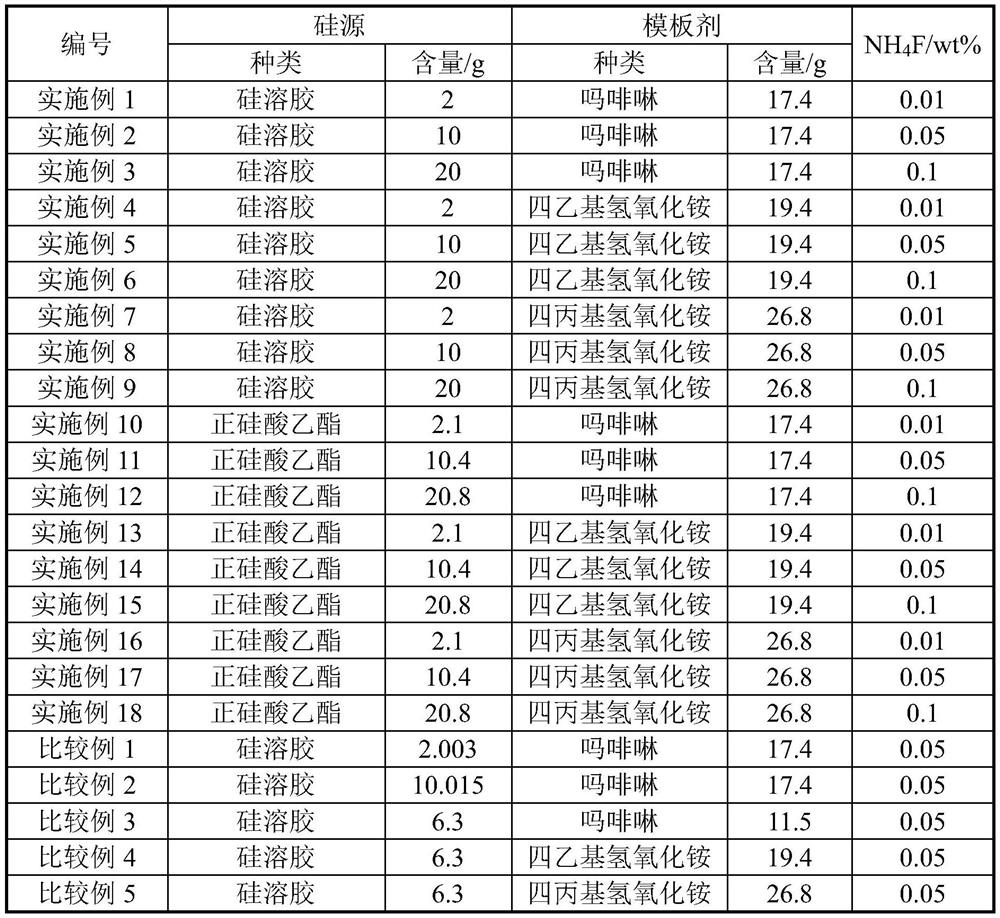

[0037] The embodiment of the present invention also provides a preparation method of a novel high-efficiency denitration catalyst, comprising the following steps:

[0038] Step 1. First, mix 20wt% copper sulfate solution with tetraethylenepentamine to form a copper ammonia complex, mix 32wt%-55wt% orthophosphoric acid with 10wt%-200wt% deionized water, and then add 5wt%-10wt% % cuproammonia complex stirring; then add 25wt%-33wt% pseudo-boehmite and / or aluminum isopropoxide, 3wt%-40wt% silica sol and / or tetraethyl orthosilicate, 25wt%-40wt% % template agent, 0.01wt%-0.1wt% ammonium fluoride, and continuously stirred at room temperature for 2h-10h.

[0039] Step 2. Put the mixed solution prepared in Step 1 in a stainless steel reaction kettle lined with polytetrafluoroethylene, age it first, then move it to an oven, raise the temperature to 150°C-280°C, and crystallize for 24h-84h. Cool to room temperature; filter and wash to neutral for many times, dry, calcined at high temper...

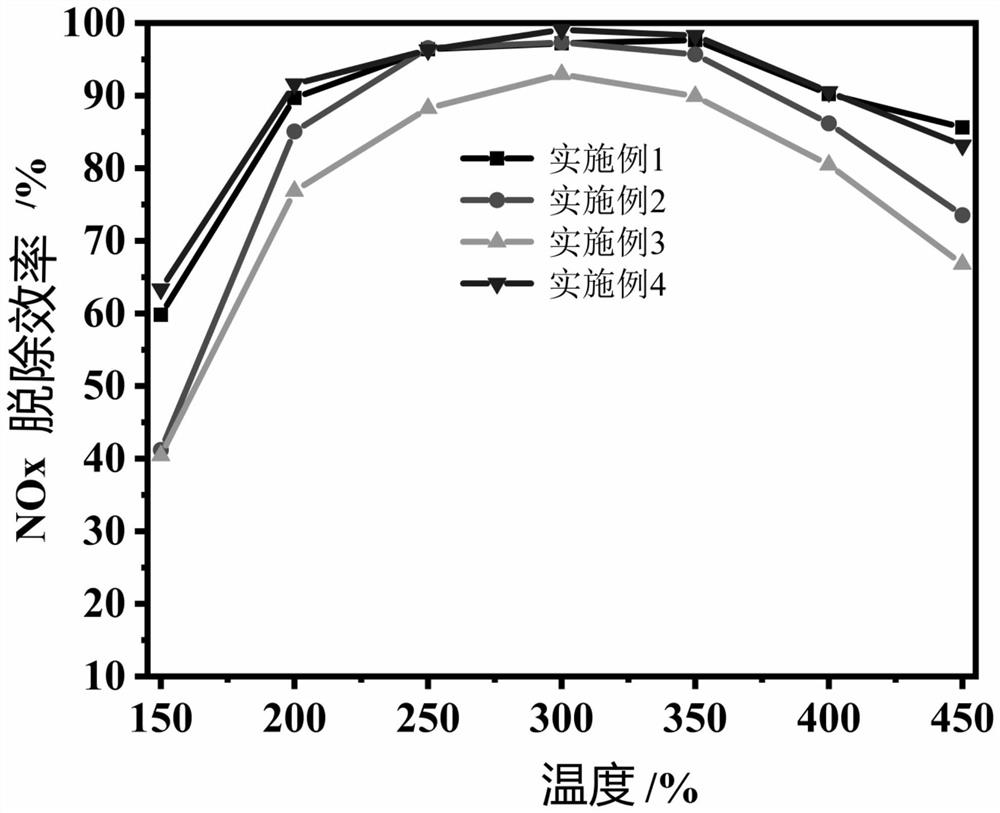

Embodiment 1

[0044] This example discloses a novel high-efficiency denitration catalyst. The preparation method of the novel denitration catalyst comprises the following steps: first prepare a 20wt% copper sulfate solution, and prepare copper sulfate and tetraethylenepentamine in a molar ratio of 1:1 Mix well, stir for 2 hours to form cuproammonia complex for later use; mix 12.3g orthophosphoric acid and 60g deionized water evenly, then add cuproammonia complex and mix well, then add 14.7g pseudo-boehmite in turn, 2g of silica sol, 17.4g of morpholine, 0.01wt% of NH 4 F, Stir at room temperature for 3-6 hours, put the above mixed solution in a stainless steel reactor lined with polytetrafluoroethylene, first age at room temperature for 12 hours, then move to an oven, heat up to 180°C for 36 hours of crystallization, After being cooled to room temperature, washed and calcined at a high temperature, a new type of high-efficiency motor vehicle denitrification catalyst is obtained.

[0045] O...

Embodiment 2

[0047] This example discloses a novel high-efficiency denitration catalyst. The preparation method of the novel denitration catalyst comprises the following steps: first prepare a 20wt% copper sulfate solution, and prepare copper sulfate and tetraethylenepentamine in a molar ratio of 1:1 Mix well, stir for 2 hours to form cuproammonia complex for later use; mix 12.3g orthophosphoric acid and 60g deionized water evenly, then add cuproammonia complex and mix well, then add 14.7g pseudo-boehmite in turn, 2g of silica sol, 17.4g of morpholine, 0.05wt% NH 4 F, Stir at room temperature for 3-6 hours, put the above mixed solution in a stainless steel reactor lined with polytetrafluoroethylene, first age at room temperature for 12 hours, then move to an oven, heat up to 180°C for 36 hours of crystallization, After being cooled to room temperature, washed and calcined at a high temperature, a new type of high-efficiency motor vehicle denitrification catalyst is obtained.

[0048] On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com