Hydrophilic-hydrophobic heterogeneous patterned surface for enhancing dropwise condensation and preparation method

A drop-shaped condensation and graphic technology, which is applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, etc., can solve the problem of low nucleation thermal resistance, super-hydrophobic surfaces, high condensation heat transfer coefficients, and inability to condense liquids. The droplet diameter and combined frequency regulation, and the high cost of laser processing and manufacturing can achieve the effects of large-scale industrial production, convenient processing and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

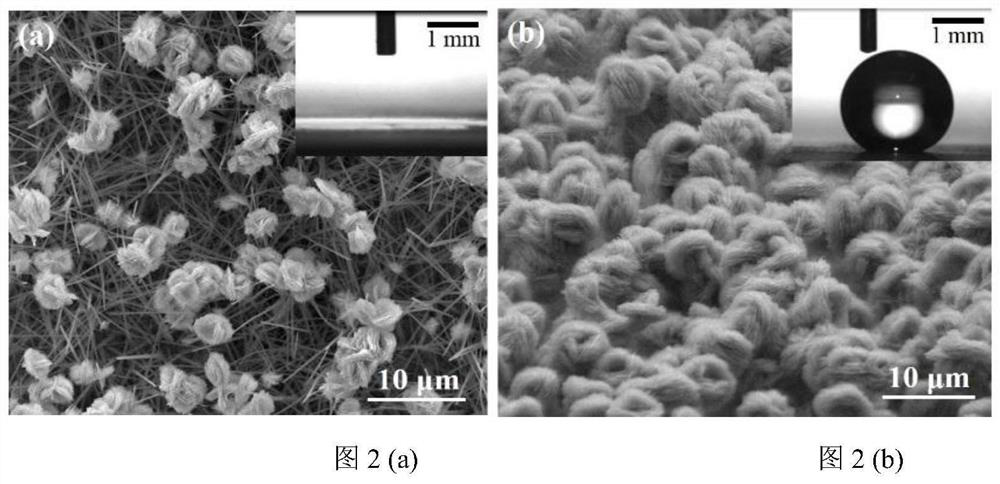

[0030] This example provides a method for preparing a highly condensed hydrophilic-hydrophobic heterogeneous patterned surface with a micro-nano composite structure. The steps for preparing the surface are as follows:

[0031] Step 1, select a circular copper substrate with a sample diameter of about 4 cm.

[0032] Grinding and polishing process: Use 400 mesh, 800 mesh, 1200 mesh, 2000 mesh and 5000 mesh sandpaper in sequence to mechanically polish and polish the surface of the copper substrate until the surface is bright and copper mirror phenomenon appears. Be careful not to scratch the surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com