Aluminum alloy workpiece with layered double hydroxide-graphene oxide silane composite coating and preparation method of aluminum alloy workpiece

A hydroxide and composite coating technology, applied in coatings, electrolytic coatings, etc., can solve the problems of high price of fluorine-containing hydrophobic compounds, weak bonding force of dip coating modification, difficult to deal with long-term erosion, etc., and achieve stable long-term protection effect. , The effect of compact structure and high anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the aluminum alloy parts with layered double hydroxide-graphene oxide silane composite coating provided by the invention comprises the following steps:

[0024] Step S0, the pretreatment step, is performed before step S1, including a polishing step and an ultrasonic cleaning step, and the specific operations are as follows:

[0025] (1) In the grinding step, the aluminum alloy parts are polished with 600-mesh, 1000-mesh, 1500-mesh, and 2000-mesh water-grinding sandpaper in sequence,

[0026] (2) Ultrasonic cleaning step, the polished aluminum alloy parts are placed in acetone, ultrasonically cleaned, and then rinsed with absolute ethanol and deionized water in order to remove oil and grease on the surface of the aluminum alloy parts.

[0027] Step S1, prepare the mixed metal salt suspension with aluminum salt and zinc salt, and adjust the pH value of the mixed metal salt suspension to 9-11.

[0028] Step S2, putting the aluminum alloy part int...

Embodiment 1

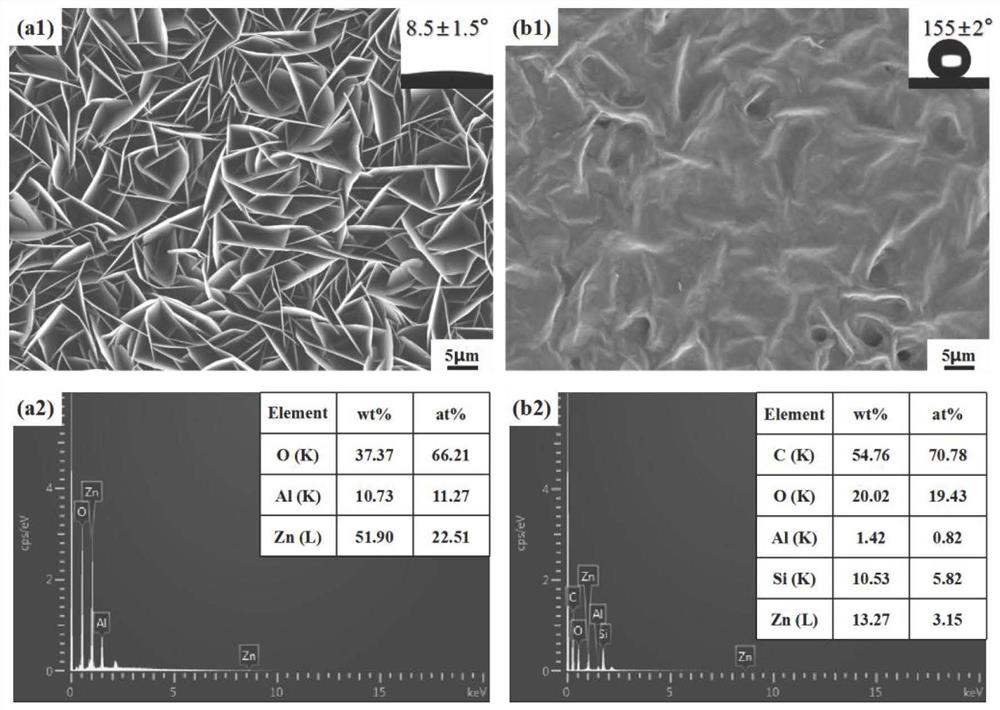

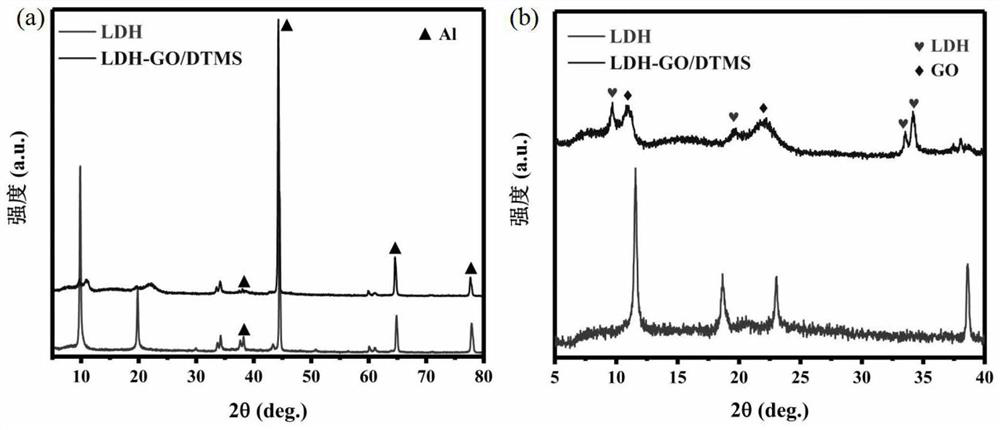

[0046] A preparation method of layered double hydroxide-graphene oxide silane composite coating, comprising the steps of:

[0047] Step S0, pretreatment of aluminum alloy parts:

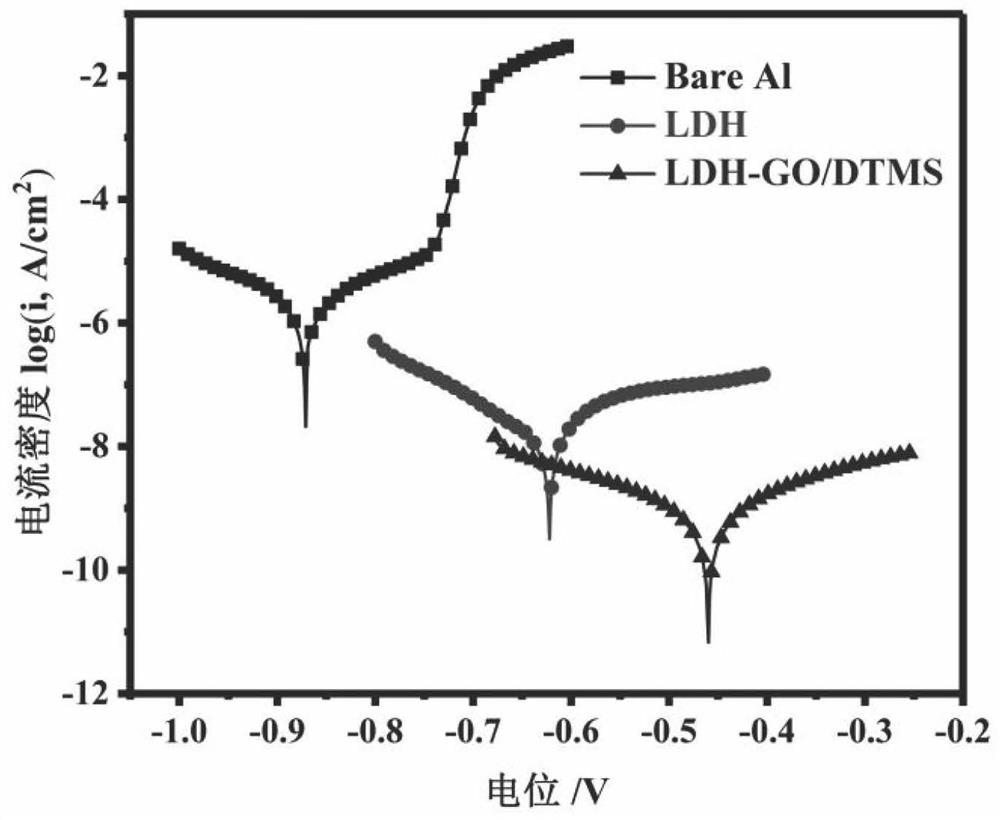

[0048] Three pieces of 40mm×13mm×2mm aluminum alloy 5052 were polished with 600#, 1000#, 1500#, 2000# water-grinding sandpaper in sequence. Then put the aluminum alloy in acetone, ultrasonically clean it with an ultrasonic cleaner for about 5 minutes, and then rinse it with absolute ethanol and deionized water in order to remove surface oil and grease. Take one piece of the aluminum alloy product obtained in this step as a blank aluminum alloy (BareAl), and continue the experiment with the remaining two pieces.

[0049] Step S1, preparation of mixed metal salt suspension:

[0050] Weigh 0.1M zinc nitrate and 0.05M aluminum nitrate and dissolve in 200mL water, measure concentrated ammonia water and dissolve in 20mL mixed metal salt suspension, and adjust pH=10.

[0051] Step S2, hydrothermal treatm...

Embodiment 2

[0069] A preparation method of layered double hydroxide-graphene oxide silane composite coating, comprising the steps of:

[0070] Step S0, pretreatment of aluminum alloy parts:

[0071] Three pieces of 40mm×13mm×2mm aluminum alloy 5052 were polished with 600#, 1000#, 1500#, 2000# water-grinding sandpaper in sequence. Put the aluminum alloy in acetone, ultrasonically clean it with an ultrasonic cleaner for about 5 minutes, and then rinse it with absolute ethanol and deionized water in order to remove surface oil and grease.

[0072] Step S1, preparation of mixed metal salt suspension:

[0073] Weigh 0.1M and dissolve in 200mL water, measure concentrated ammonia water and dissolve in 20mL mixed metal salt suspension, adjust pH=9.

[0074] Step S2, hydrothermal treatment co-precipitation:

[0075] Add the aluminum alloy obtained in step S0 to the solution obtained in step S1, place it at 60° C. for 12 hours, take it out and dry it naturally in the air. Take one piece of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com