A method for producing high-strength and high-corrosion-resistant steel by thin strip continuous casting

A high corrosion resistance and continuous casting technology, applied in the field of continuous casting technology, can solve the problems of slow solidification and cooling speed of cast slab, deterioration of plate shape, uneven microstructure, etc., to improve the quality of plate shape, performance stability and energy consumption and CO2 emission reduction, the effect of homogenizing the internal microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention is further set forth in the following examples, but these embodiments are not limited to the present invention. Any variations made in the practice of the present invention will be within the scope of the invention in the claims.

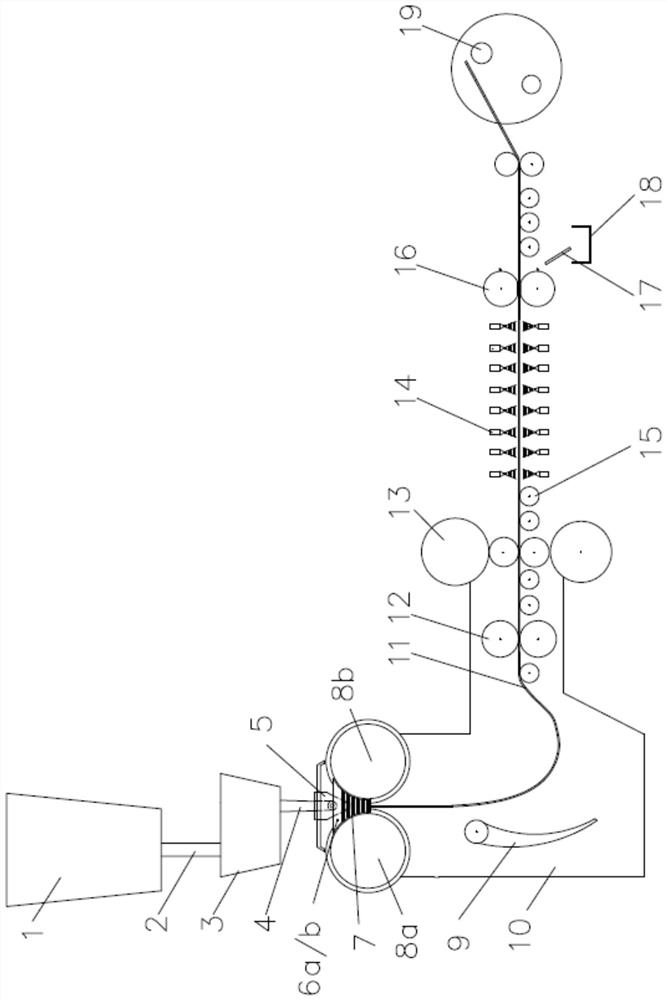

[0090] See figure 1 The steel water that meets the chemical composition of the present invention is formed by large bag 1, through the large bag long water port 2, the intermediate package 3, the immersion moisture port 4, and the discharge device 5 directly cast a crystallization of two relative rotation and quick cooling. In the molten tank 7, the rollers 8a, 8b, and the side sealing plate devices 6a, 6b, the steel water is solidified on the circumferential surface of the crystal rollers 8a, 8b, and then the coagulation shell is formed and gradually growing the minimum slit in the two jaw roll rolls. (NIP point) Form 1.5-3mm thick cast tape 11; the diameter of the crystalline roller of the present invention is between 500-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com