Chelating coordination type phosphorus-boron-nitrogen synergistic flame retardant and preparation method thereof

A synergistic flame retardant and coordination technology, used in the field of flame retardant materials, can solve the problems of insufficient surface treatment technology, poor compatibility between flame retardants and materials, and poor thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

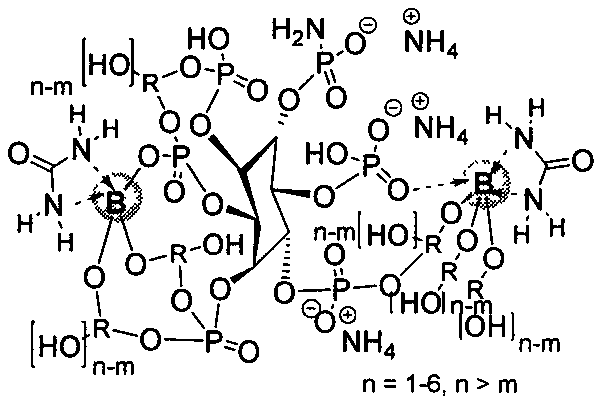

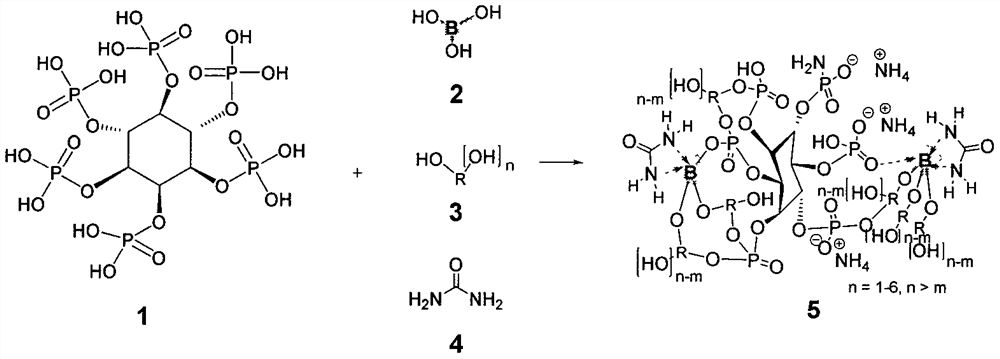

[0012] The invention provides a chelating coordination type phosphorus-boron-nitrogen synergistic intumescent flame retardant and a preparation method thereof, which is characterized in that the specific steps are as follows:

[0013] 1) Add reactant phytic acid, polyhydric alcohol and boric acid and solvent in the flask, preferably (or without solvent), at a certain temperature, stir the reaction until the end of the reaction;

[0014] 2) After the reaction is completed, the solvent is removed (there is no such step without a solvent) to obtain an intermediate;

[0015] 3) Add deionized water and urea to the intermediate product, and continue to heat and stir the reaction at a certain temperature until the end of the reaction to obtain a viscous liquid, which is the target flame retardant.

[0016] 4) Use the target flame retardant directly as an additive, or configure it into an aqueous solution with a certain solubility, and arrange the target flame retardant by means of di...

Embodiment 1

[0032] 1) Add the reactant phytic acid (0.4mol), ethylene glycol (0.8mol) and boric acid (0.4mol) and solvent toluene 100mL in the flask, stir the water separation and reflux reaction until the reaction is completed;

[0033] 2) After the reaction is completed, cool down and remove the solvent toluene to obtain an intermediate;

[0034] 3) Add deionized water (0.5 mol) and urea (2.0 mol) to the intermediate product, heat and stir at 100°C until the reaction ends at pH=2-8, and a viscous liquid is obtained, which is the target flame retardant.

[0035] 4) The prepared flame retardant is configured into a 120g / L aqueous solution, and the cotton fabric is finished by dipping, padding, ultrasonication, etc. After drying and curing, the target flame retardant product can be obtained. After 50 washing cycles of the obtained cotton fabric, the oxygen index >28 and above, the vertical burning carbon length is less than 60mm.

Embodiment 2

[0037] 1) Add reactant phytic acid (0.4mol), glycerol (0.6mol) and boric acid (0.4mol) and solvent toluene 100mL in the flask, stir and reflux until the reaction ends;

[0038] 2) After the reaction is completed, cool down and remove the solvent toluene to obtain an intermediate;

[0039] 3) Add deionized water (0.5 mol) and urea (1.0 mol) to the intermediate product, heat and stir at 100°C until the reaction is completed at pH=2-8, and a viscous liquid is obtained, which is the target flame retardant.

[0040] 4) The prepared flame retardant is configured into a 90g / L aqueous solution, and the cotton fabric is finished by dipping, padding, ultrasonication, etc. After drying and curing, the target flame retardant product can be obtained. After 50 washing cycles of the obtained cotton fabric, the oxygen index >28 and above, the vertical burning carbon length is less than 60mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com