Preparation method of aerogel-containing polyester fibers

A polyester fiber and polyester fiber masterbatch technology, applied in the field of clothing fabrics, can solve problems such as poor spinnability, uneven particle size of airgel, and uneven mixing, so as to improve thermal insulation performance and expand a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

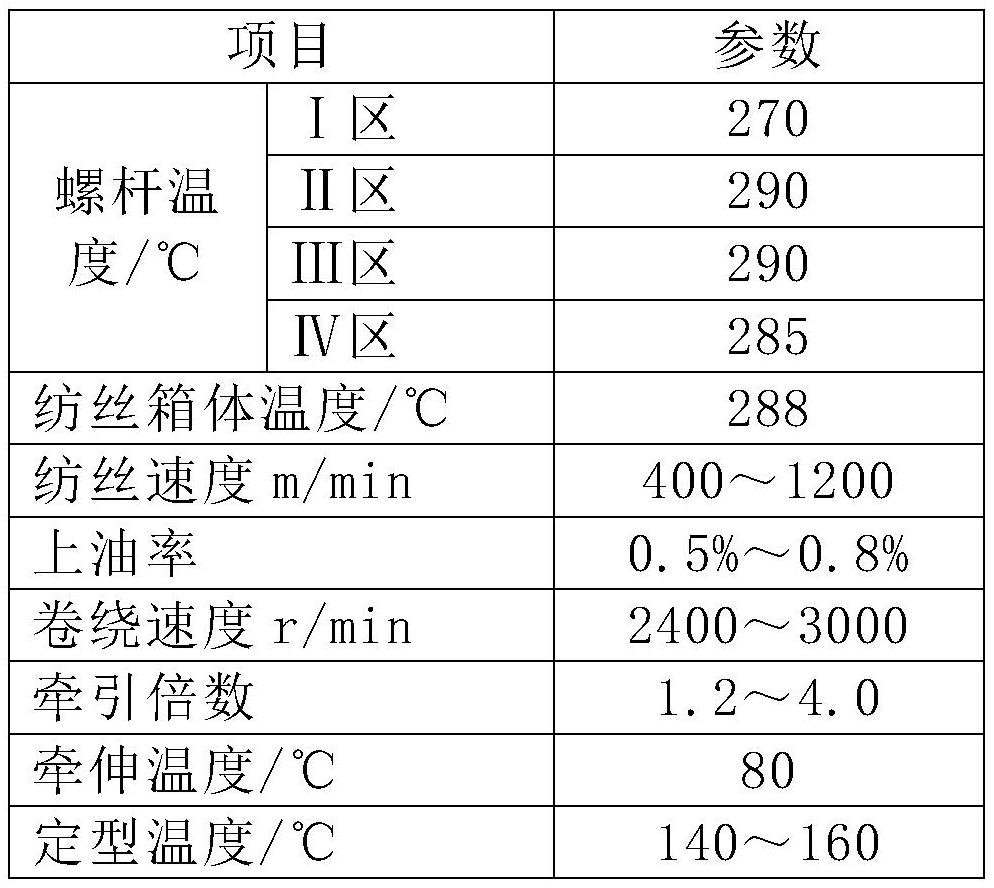

[0031] A kind of preparation method of airgel-containing polyester fiber provided by the invention comprises the following steps:

[0032] In step 1, the airgel microspheres are uniformly mixed with the PET powder to obtain a mixed powder. Step 1 includes the following subdivision steps:

[0033] 1. Selection of powder:

[0034] a. Select silica airgel microspheres: average particle size 20-80nm, porosity 80%-95%, specific surface area 200-900m 2 / g, apparent density 0.2~0.8g / cm 3 . In a vacuum box, after drying at 60°C for 6 hours, the temperature is raised to 120°C and kept for 2 hours, so that the water content of the airgel microspheres is less than 100ppm.

[0035] Airgel microspheres are microspheres with regular shape and controllable size and porous structure, which essentially have all the advantages of airgel. Silica airgel microspheres are used as fillers for modified polyester fibers It's an excellent solution.

[0036] b. The first PET chip is pulverized, an...

Embodiment 1

[0054] Select silica airgel microspheres: average particle size 60nm, porosity 85%, specific surface area 400m 2 / g, apparent density 0.4g / cm 3 , in a vacuum box, dry at 60°C for 6 hours, then raise the temperature to 120°C for 2 hours, so that the moisture content of the powder is less than 100ppm. Grind PET slices with an average particle size of 10 μm, dry at 60°C for 6 hours, then heat up to 120°C for 4 hours, and fully dry to make the moisture content of the powder less than 100ppm. EVA acts as a dispersant. Choose Antioxidant 1010.

[0055] Calculated in parts by mass, mix 80 parts of PET powder, 20 parts of silica airgel microspheres, 1.5 parts of dispersant, and 0.8 parts of antioxidant, shake in ultrasonic for 0.3h, then stir in a mixer for 1h at a speed of 150r / min to obtain a uniformly mixed powder.

[0056] Mix 30 parts by mass of the above dry mixed powder with 70 parts by mass of PET slices, stir in a mixer for 1 hour at a speed of 200r / min, mix thoroughly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com