High-strength pollution-resistant composite reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane, high-strength technology, used in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of poor flux and antibacterial performance of reverse osmosis membranes, no interaction between dopamine and silver, and has not yet been found Carbon nanowire applications and other issues, to achieve the effect of excellent dispersion performance, high mechanical strength and stability, and increased use stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

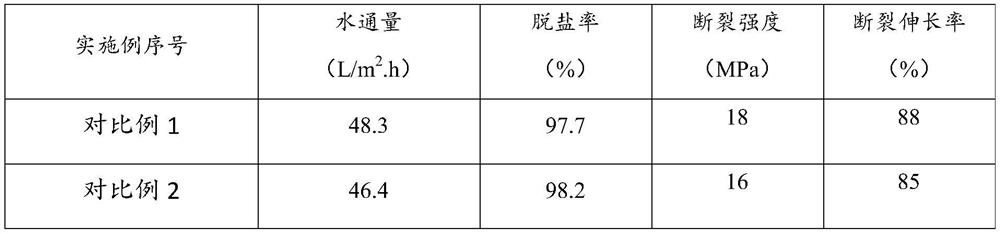

Examples

Embodiment 1

[0025] Add carbon nanowires into a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, heat and ultrasonicate at 60°C for 4 hours, then repeatedly wash with deionized water and centrifuge until the pH value is 7, then dry at 70°C to obtain acidification carbon nanowires.

[0026] The polysulfone ultrafiltration membrane (PSF) cleaned with isopropanol was immersed in the aqueous phase solution with a pH value of 8 for 30s, in which polyetherimide modified carbon nanowires (0.5wt%), m-phenylenediamine ( 2.5wt%), triethylamine (0.2wt%), camphorsulfonic acid (0.3wt%), after the excess solution was removed by a rubber roller, immersed in the oil phase solution for 60s, wherein trimesoyl chloride (0.07wt%), solvent It is n-hexane, and after taking it out, it is heat-treated at 70°C for 10 minutes to obtain a high-strength composite reverse osmosis membrane;

Embodiment 2

[0028] Except that the carbon nanowire content was replaced by 1 wt%, other conditions were the same as in Example 1, and a high-strength composite reverse osmosis membrane was obtained.

Embodiment 3

[0030] Except that the content of carbon nanowires was replaced by 2 wt%, other conditions were the same as in Example 1, and a high-strength composite reverse osmosis membrane was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com