Preparation method of silver-silicon catalyst, silver-silicon catalyst and application of silver-silicon catalyst

A catalyst, silver-silicon technology, applied in the field of preparation of silver-silicon catalysts, can solve the problems of high cost, unfavorable silver reduction, less lattice of Ag particles, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

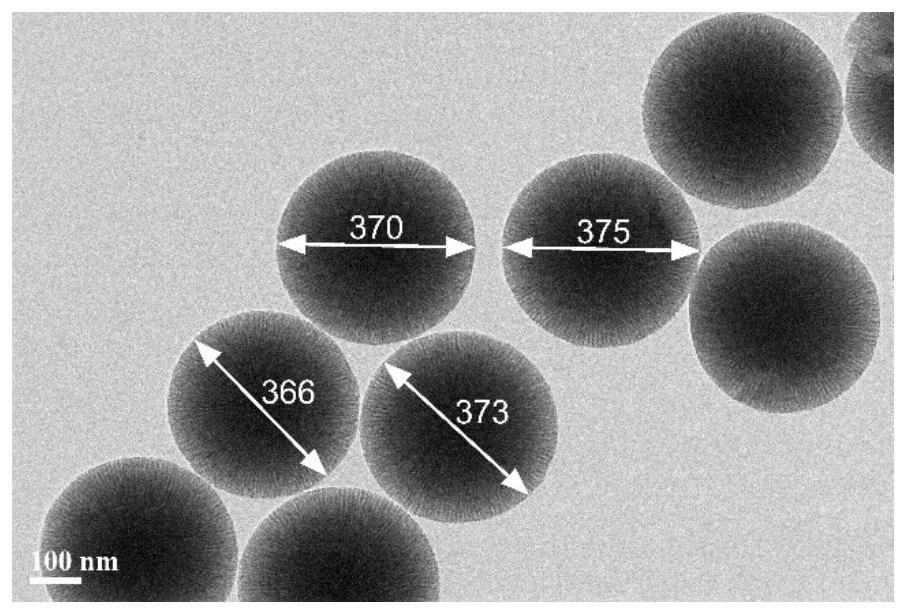

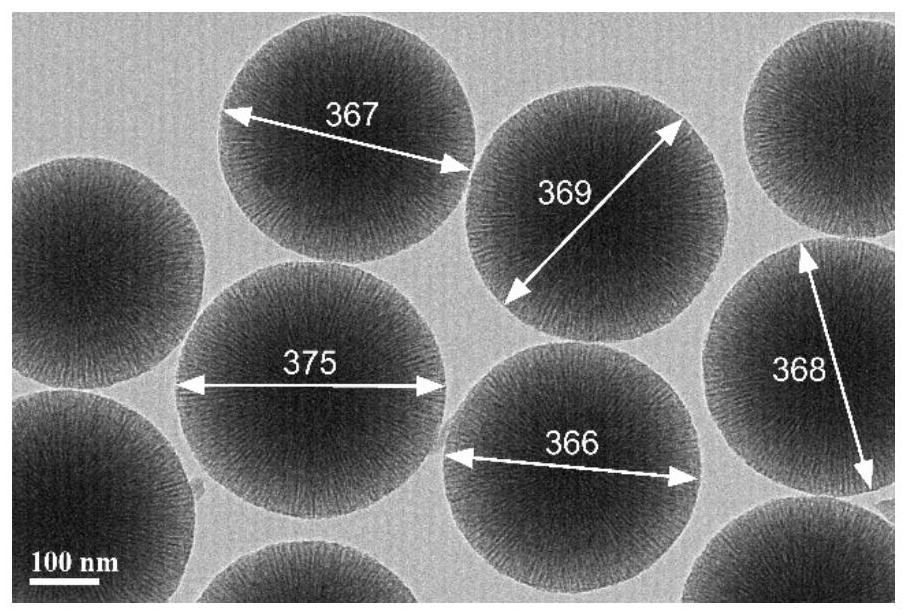

[0056] Example 1. Preparation of mesoporous silica nanospheres

[0057] The preparation of the mesoporous silica nano-microspheres of the present embodiment includes the following steps:

[0058] (1), dissolve 15g surfactant cetyl trimethyl ammonium chloride in 120ml deionized water, add 0.4g triethanolamine, be warming up to 60 ℃, under rotating speed 150r / min, stir 1 hour to obtain surface active Agent-aqueous solution as water phase; 7.5 g of tetraethoxysilane was dissolved in 25 g of cyclohexane as oil phase.

[0059] (2), the oil phase of step (1) was added dropwise to the water phase, the control temperature was 60 ° C, the rotating speed was 100 r / min, and the stirring was continued for 20 hours; after stirring, centrifugation was performed, and the sediment was washed with 120 ml of ethanol to remove residues to obtain a white solid;

[0060] (3), the white solid obtained in step (2) was dried at 120° C. for 4 hours, and then calcined at 550° C. for 4 hours to remove...

Embodiment 2

[0062] Example 2. Preparation of mesoporous silica nanospheres

[0063] The preparation method of this embodiment is basically the same as that of embodiment 1, and the difference is:

[0064] In step (1), dissolve 15g of surfactant cetyltrimethylammonium chloride in 300ml of deionized water, add 0.6g of triethanolamine as the water phase; dissolve 7.5g of tetraethoxysilane in 18.75g in cyclohexane as the oil phase.

[0065] In step (2), the temperature was controlled to be 50° C., the rotational speed was 150 r / min, and the stirring was continued for 36 hours.

[0066] The mesoporous silica nanospheres were obtained, marked as M2.

[0067] The above-mentioned M2 was observed with a transmission electron microscope, and the microscopic morphology was the same as the figure 1 similar. The diameter of M2 prepared in this example is about 490nm, and the BET specific surface area is 479m 2 g -1 , the hole volume is 1.14m 3 g -1 , with an average pore size of 9.37 nm.

Embodiment 3

[0068] Example 3. Preparation of mesoporous silica nanospheres

[0069] The preparation method of this embodiment is basically the same as that of embodiment 1, and the difference is:

[0070] In step (1), 15g of surfactant cetyltrimethylammonium chloride was dissolved in 90ml of deionized water, and 0.3g of triethanolamine was added as the water phase; 7.5g of tetraethoxysilane was dissolved in 31.25g of in cyclohexane as the oil phase.

[0071] In step (2), the temperature was controlled to be 70° C., the rotational speed was 50 r / min, and the stirring was continued for 12 hours.

[0072] The mesoporous silica nanospheres were obtained, marked as M3.

[0073] The above-mentioned M3 was observed with a transmission electron microscope, and the microscopic morphology was the same as the figure 1 similar. The diameter of M3 prepared in this example is about 220nm, and the BET specific surface area is 906m 2 g -1 , the hole volume is 0.49m 3 g -1 , with an average pore s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com