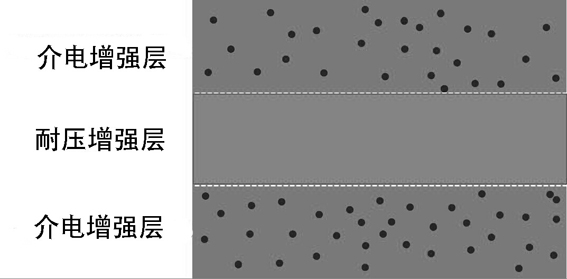

Composite dielectric material with three-layer structure and preparation method thereof

A dielectric material and three-layer structure technology, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of decreased energy storage efficiency, reduced breakdown strength of composite materials, and limited improvement of energy storage performance. Achieve the effect of improving energy storage efficiency, improving breakdown performance and reducing conductance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

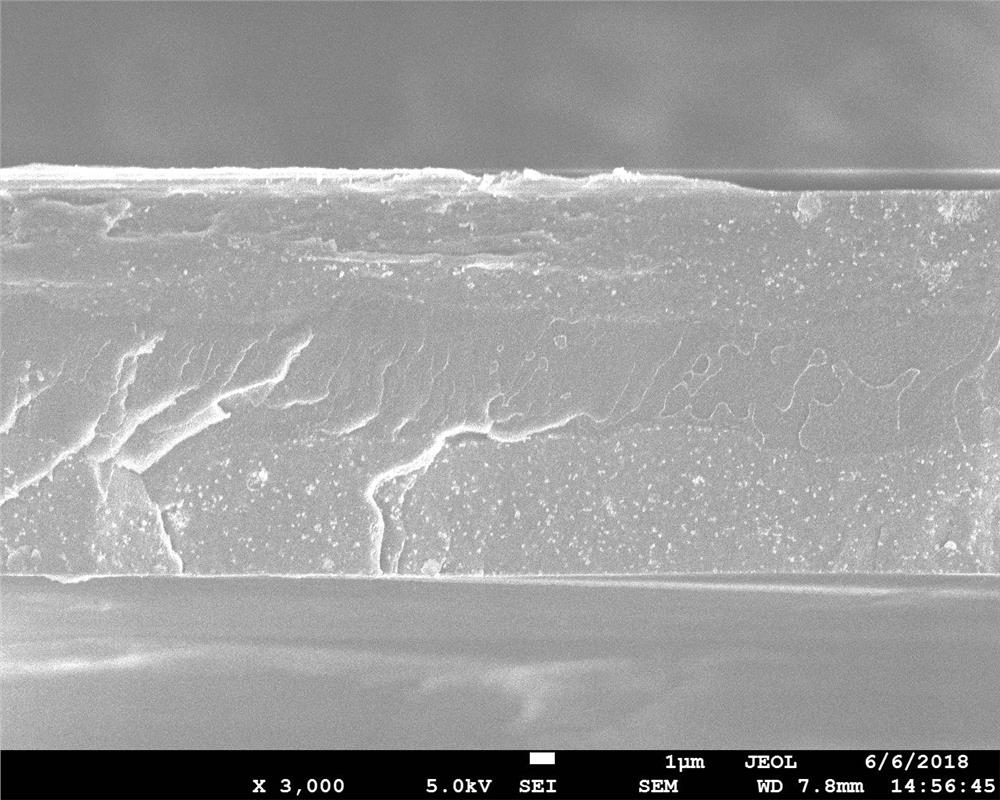

[0034] Dissolve 0.45 g of polyvinylidene fluoride-hexafluoropropylene powder in 10 mL of N,N-dimethylformamide solution, stir overnight until completely dissolved, then add 0.05 g of barium titanate nanoparticles to the above solution, continue After stirring for 1 h, ultrasonic treatment was performed for 30 min until the barium titanate nanoparticles were completely dispersed. The mixed solution prepared above was evenly coated on a clean and flat quartz glass plate with a spatula, and quickly dried in an oven at 60 °C for 24 h to obtain the outer The layer is a polyvinylidene fluoride-hexafluoropropylene / barium titanate film, that is, a dielectrically enhanced film, and the film thickness is 5 μm;

[0035] Dissolve 0.5 g of polymethyl methacrylate in 10 mL of N,N-dimethylformamide solution, stir overnight until completely dissolved, and apply the solution prepared above evenly on a clean and flat quartz glass plate with a spatula , quickly placed in an oven at 60 °C for 24 ...

Embodiment 2

[0039]Dissolve 0.95 g of polyvinylidene fluoride powder in 10 mL of N,N-dimethylformamide solution, stir overnight until completely dissolved, then add 0.05 g of barium strontium titanate nanoparticles to the above solution, and continue stirring for 1 h After ultrasonic treatment for 30 min until the barium strontium titanate nanoparticles were completely dispersed, the mixed solution prepared above was evenly coated on a clean and flat quartz glass plate with a spatula, and quickly dried in an oven at 60 °C for 24 h to obtain the outer layer It is a film of polyvinylidene fluoride / barium strontium titanate, that is, a dielectrically enhanced film, with a film thickness of 6 μm;

[0040] Dissolve 0.5 g of polycarbonate in 10 mL of N,N-dimethylformamide solution, stir overnight until completely dissolved, apply the above-prepared solution evenly on a clean and flat quartz glass plate with a spatula, and quickly put Dry in an oven at 70 °C for 24 h to obtain a film with a polyc...

Embodiment 3

[0043] Dissolve 0.9 g of polyvinylidene fluoride-chlorotrifluoroethylene powder in 10 mL of N,N-dimethylformamide solution, stir overnight until completely dissolved, then add 0.1 g of titanium dioxide nanoparticles to the above solution, and continue stirring After 1 h, ultrasonic treatment was performed for 30 min until the titanium dioxide nanoparticles were completely dispersed. The mixed solution prepared above was evenly coated on a clean and flat quartz glass plate with a spatula, and quickly dried in an oven at 60 °C for 24 h. The outer layer was obtained. The polyvinylidene fluoride-chlorotrifluoroethylene / titanium dioxide film is a dielectrically enhanced film, and the film thickness is 8 μm;

[0044] Dissolve 1 g of polypropylene in 10 mL of N,N-dimethylformamide solution, stir overnight until completely dissolved, apply the above-prepared solution evenly on a clean and flat quartz glass plate with a spatula, and quickly put it in Dry in an oven at 65 °C for 48 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com