Preparation and application of bismuth ferrite loaded graphene composite material

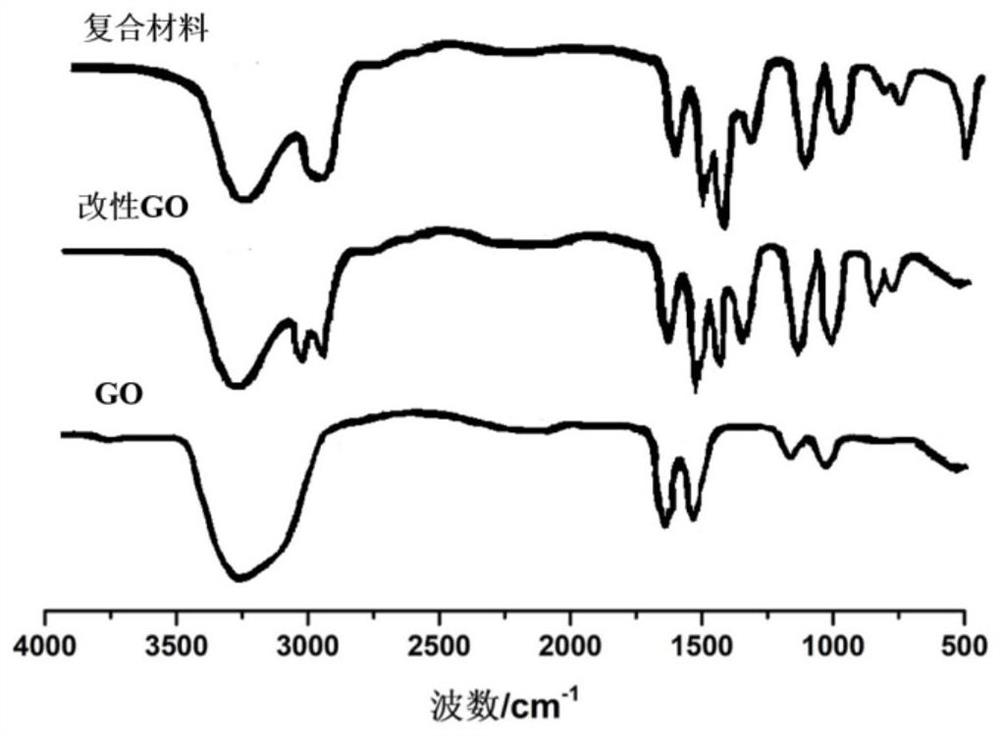

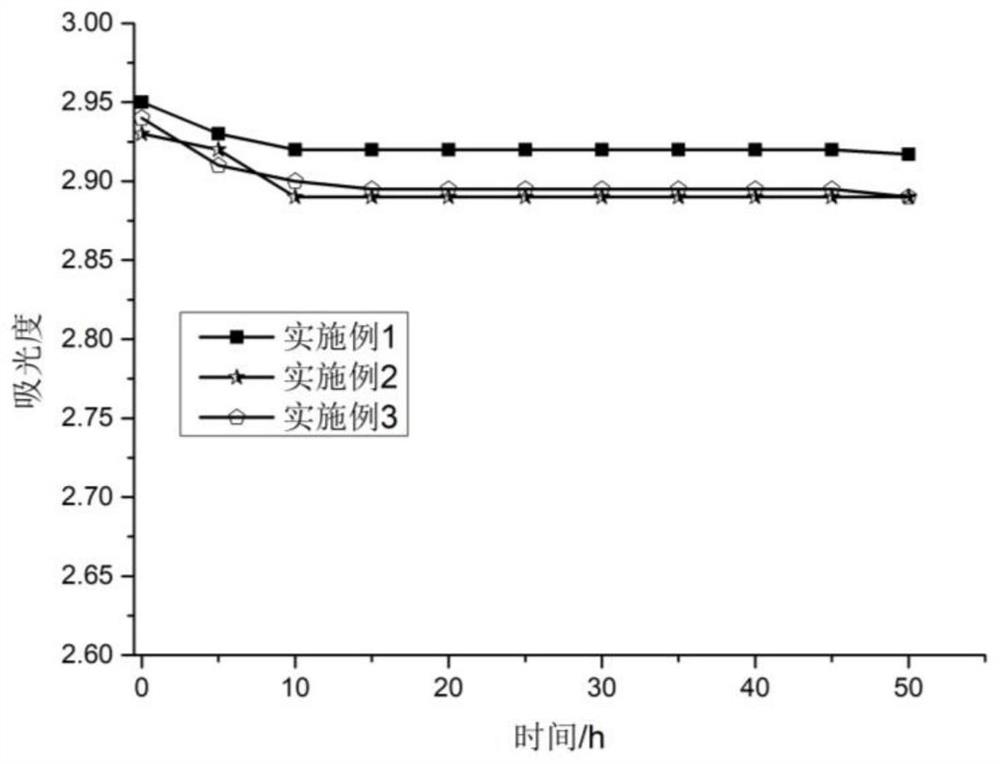

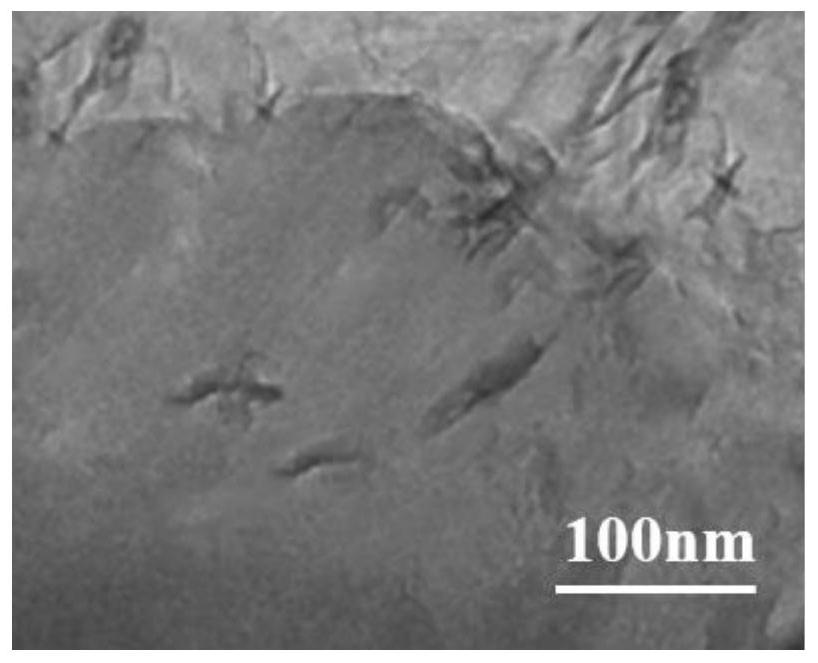

A composite material and graphene technology, applied in the field of visible light catalysis, to achieve the effects of high degradation stability, improved dispersion, and excellent photocatalytic degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of bismuth ferrite used in the present invention is as follows:

[0041] Dissolve bismuth nitrate pentahydrate and ferric nitrate nonahydrate in nitric acid with the ratio of the amount of substance being 1:1, and stir until the crystals are all dissolved to obtain nitric acid solution; the above nitric acid solution is slowly added dropwise to excess potassium hydroxide solution, An orange-yellow precipitate is produced, continue to add dropwise until the precipitate is complete, stir rapidly for 15-35 minutes to mix evenly, centrifuge, and wash to obtain bismuth ferrite.

[0042] The technical solution of the present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings:

Embodiment 1

[0044] A preparation method of bismuth ferrite loaded graphene composite material, specifically comprising the following steps:

[0045] (1) Preparation of modified graphene

[0046]In parts by weight, add 4.5 parts by weight of flake graphite powder and 2.5 parts by weight of sodium nitrate to the beaker, then add concentrated sulfuric acid to make the concentration of graphite powder 0.02g / mL, put the beaker in an ice bath, and continue to add 25 parts by weight. Parts by weight of potassium permanganate, the temperature was kept at 25°C by stirring, and heated in a water bath at 25°C for 25 minutes after 5 minutes. Add deionized water to the beaker, when the temperature rises to 80°C, place it at room temperature for 8 minutes, after the temperature drops to 55°C, keep it at this temperature for 6 minutes, then add 100 parts by weight of normal temperature hydrogen peroxide, stop reaction, suction filtration, washing, and drying to obtain graphene oxide.

[0047] Put usni...

Embodiment 2

[0051] A preparation method of bismuth ferrite loaded graphene composite material, specifically comprising the following steps:

[0052] (1) Preparation of modified graphene

[0053] In parts by weight, add 6 parts by weight of flake graphite powder and 4 parts by weight of sodium nitrate to the beaker, then add concentrated sulfuric acid to make the concentration of graphite powder 0.035g / mL, place the beaker in an ice bath, and continue to add 21 Parts by weight of potassium permanganate, the temperature was kept at 25°C by stirring, and heated in a water bath at 22°C for 30 minutes after 3 minutes. Add deionized water to the beaker, when the temperature rises to 85°C, place it at room temperature for 10 minutes, after the temperature drops to 50°C, keep it at this temperature for 8 minutes, then add 90 parts by weight of normal temperature hydrogen peroxide, stop reaction, suction filtration, washing, and drying to obtain graphene oxide.

[0054] Put usnic acid and the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com