Preparation method of polyurethane adhesive

A technology of polyurethane adhesives and catalysts, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., and can solve the problems of limited application, poor heat resistance, antistatic and water resistance, and low strength of water-based polyurethane adhesives. , to achieve the effects of easy peeling, excellent antistatic performance, long-term hydrolysis resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

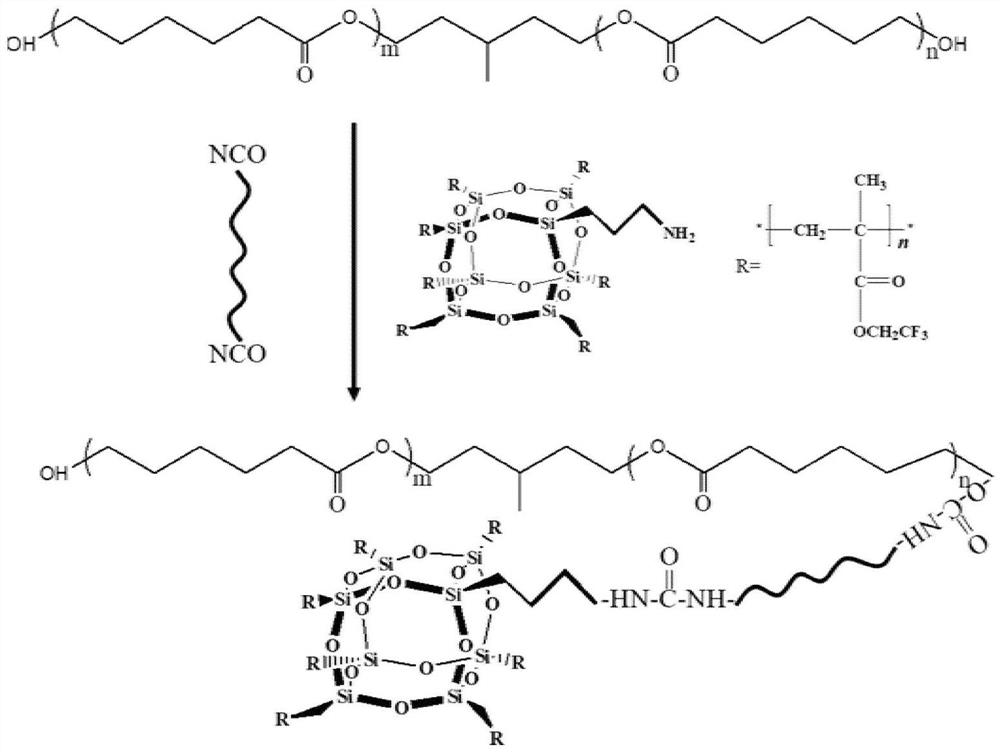

Method used

Image

Examples

Embodiment 1

[0033]Weigh 100g of caprolactone and 10g of MDP in a three-necked flask, stir and add 0.5g of stannous isooctanoate, carry out ring-opening polymerization at 120°C for 4 hours, cool the reaction mixture to room temperature, and then dissolve in Methyl chloride (100 mL). Pour the obtained product into an excess of n-hexane and ether mixed solution (2 / 1, v / v) and centrifuge for three times. The precipitate is dried in a vacuum drying oven at 50°C for 24 hours. The precipitate is the hydroxyl-terminated product. Polycaprolactone has a molecular weight of 2000. Weigh a certain mass of hydroxyl-terminated polycaprolactone, add 10 parts of modifier by mass; 1 part of defoamer; 0.5 part of antioxidant; 1wt% of antistatic agent, fully stirred until uniform The main agent of polyurethane adhesive.

[0034]Weigh isophorone diisocyanate (IPDI, 2223g; 10mol), place it in the reactor and heat it to 80°C, add polypropylene glycol (PPG, MW=1000; 1000g, 1mol) within 4 hours, and keep the temperature a...

Embodiment 2

[0037]Weigh 100g of caprolactone and 10g of MDP in a three-necked flask, stir and add 0.5g of stannous isooctanoate, carry out ring-opening polymerization at 120°C for 4 hours, cool the reaction mixture to room temperature, and then dissolve in Methyl chloride (100 mL). Pour the obtained product into an excess of n-hexane and ether mixed solution (2 / 1, v / v) and centrifuge for three times. The precipitate is dried in a vacuum drying oven at 50°C for 24 hours. The precipitate is the hydroxyl-terminated product. Polycaprolactone has a molecular weight of 2000. Weigh a certain mass of hydroxyl-terminated polycaprolactone, add 10-12 parts of modifier; 1-2 parts of defoamer; 0.5-1 part of antioxidant; 0.5-2wt% of antistatic After mixing thoroughly until uniform, the polyurethane adhesive main agent one is obtained.

[0038]Weigh isophorone diisocyanate (IPDI, 1333.8g; 6mol), place it in the reactor and heat it to 90°C, add polypropylene glycol (PPG, MW=1000; 1000g, 1mol) within 3 hours, and ...

Embodiment 3

[0041]Weigh 100g of caprolactone and 10g of MDP in a three-necked flask, stir and add 0.5g of stannous isooctanoate, carry out ring-opening polymerization at 120°C for 4 hours, cool the reaction mixture to room temperature, and then dissolve in Methyl chloride (100 mL). Pour the obtained product into an excess of n-hexane and ether mixed solution (2 / 1, v / v) and centrifuge for three times. The precipitate is dried in a vacuum drying oven at 50°C for 24 hours. The precipitate is the hydroxyl-terminated product. Polycaprolactone has a molecular weight of 2000. Weigh a certain mass of hydroxyl-terminated polycaprolactone, add 10-12 parts of modifier; 1-2 parts of defoamer; 0.5-1 part of antioxidant; 0.5-2wt% of antistatic After mixing thoroughly until uniform, the polyurethane adhesive main agent one is obtained.

[0042]Weigh isophorone diisocyanate (IPDI, 1333.8g; 10mol), place it in the reactor and heat it to 85°C, mix 2g of dibutyltin dilaurate catalyst into polypropylene glycol, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com