Artificially synthesized tetragonal system petalite and manufacturing method thereof

A technology of permeable feldspar and tetragonal crystal system is applied in the field of artificial synthesis of permeable feldspar of tetragonal crystal system and its manufacture, which can solve the large fluctuation of the price of chemical lithium salt and the inability of unilateral formability to meet the large-scale production of daily heat-resistant ceramics requirements and other issues, to achieve the effect of breaking through resource bottleneck constraints, broadening supply sources and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

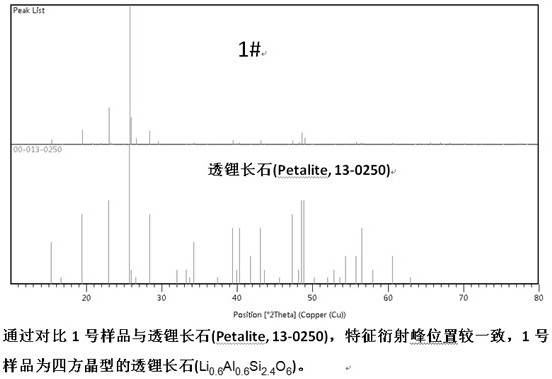

Embodiment 1

[0034]According to the measurement requirements for the chemical components of artificial synthetic penetrating feldspar, set the feed amount of the base material formula to 100%, adopt the dry processing process, and weigh and feed as follows:

[0035]Weigh 54.0% of 1200 mesh commercial silicon powder, 35% of ultra-fine kaolin powder, 3% of industrial lithium carbonate powder, 4% of lithium fluoride, 1% of barium fluoride and 3% of lithium feldspar fine powder (as an additional amount ), put into the screw mixer to stir the mixture.

[0036]Weigh 3% anhydrous lithium chloride and prepare a 50% solution. Spray the dry powder while stirring in the way of atomization spraying until the lithium chloride solution is completely added to the powder and make The powder is evenly wetted.

[0037]The stirred wet material is trapped for 24 hours and enters the press forming process.

[0038]The above green powder is pressed into a round bar or square green body with a length of 3 to 5 cm. The formed blan...

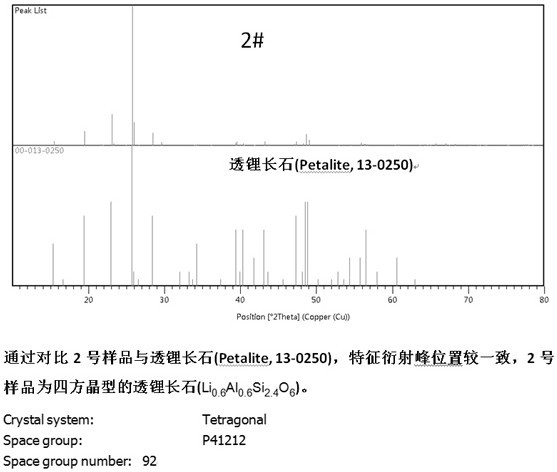

Embodiment 2

[0041]According to the measurement requirements of the chemical components of artificial synthetic penetrating feldspar, set the dosage of the base material formula to 100%, and adopt the wet processing technology, and operate in sequence according to the following steps.

[0042]One stage feeding: weigh 55.0% of quartz sand, according to the material: ball: water-1:1.5:0.5 into the ball mill, ball mill for 48 hours.

[0043]Feeding in the second stage: weigh 37% of kaolin concentrate (measured by dry weight), weigh 8% of lithium fluoride, weigh 3% of lithospere ore fine sand (additional amount), and 80% of the second stage feed Add water and continue grinding for 12 hours. Unload the slurry after grinding in place.

[0044]Referring to Example 1, continue to complete the subsequent process flow: mud squeezing, drying, crushing, green compact powder preparation, press forming, roasting, and clinker crushing until the finished product is put into storage.

[0045]Since the formulation of this ex...

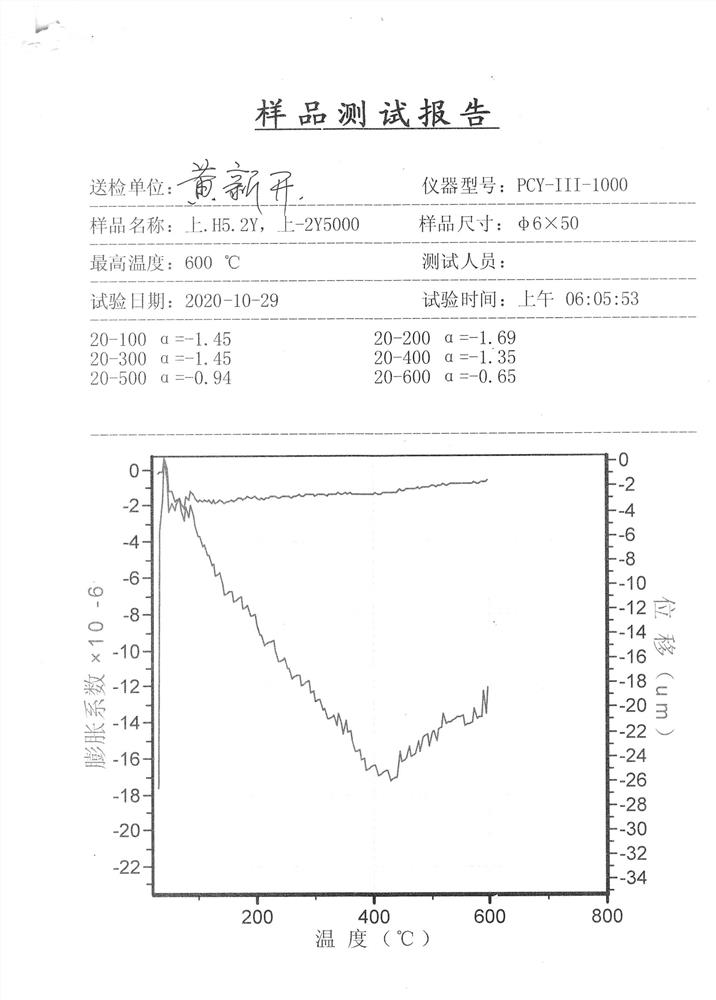

Embodiment 3

[0048]According to the measurement requirements for the chemical components of artificial synthetic penetrating feldspar, set the feed amount of the base material formula to 100%, adopt the dry processing process, and weigh and feed as follows:

[0049]Weigh 34.0% of 1200 mesh commercial silicon micropowder, 61.0% of 6.0 grade spodumene ultrafine powder, 2% of magnesium fluoride, and 2% of spodumene fine powder (additional amount), and put them into a screw mixer for mixing. Weigh 3% lithium chloride and prepare a 40% lithium salt solution for later use. Refer to Example 1, continue to complete the subsequent solution spraying, blank powder homogenization, compression molding, kiln roasting (firing temperature 1340°C, holding at 1290°C for 2 hours), clinker crushing, and finished product classification.

[0050]The expansion coefficient of the sample of Example 3 was tested, and the results were as followsFigure 4 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of expansion | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com