Polishing layer of chemical mechanical polishing pad and preparation method therefor

A chemical mechanical and polishing layer technology, which is applied in the polishing layer of chemical mechanical polishing pads and its preparation field, can solve the problems of polyurethane polishing layer dynamic mechanical properties, heat resistance, poor hydrolytic stability, poor stability, darkening of color, etc. problem, to achieve the effect of prolonged gel time, good elastic modulus retention and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

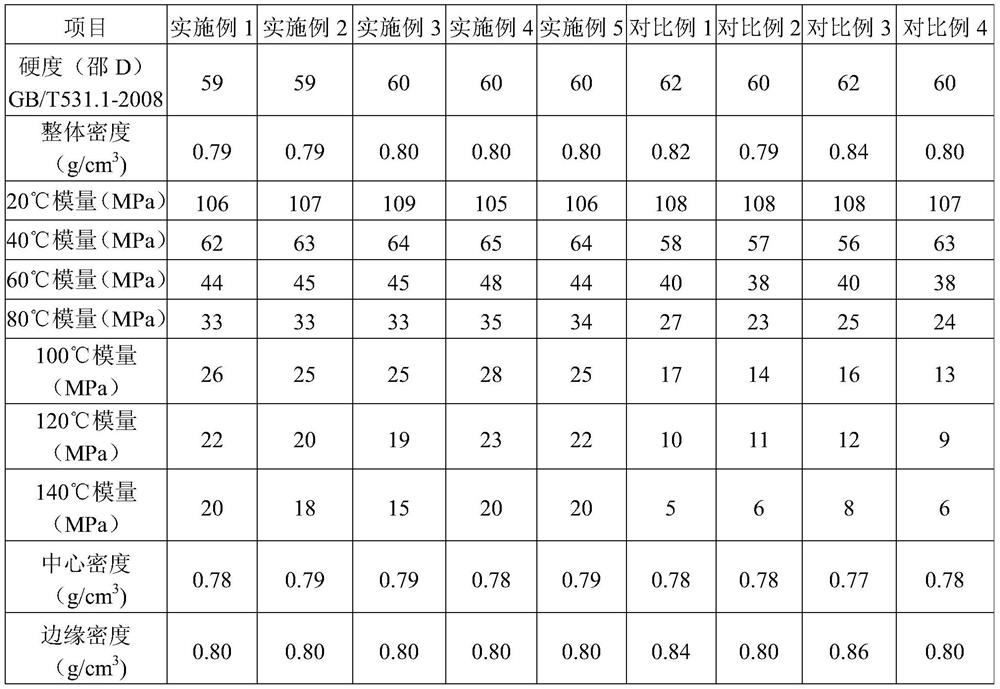

Examples

Embodiment 1

[0039] Isocyanate prepolymer component: Take 34 parts of TDI-100, 53 parts of PolyTHF 1000, 6 parts of DEG, and react at 75°C for 2 hours to obtain an initial prepolymer with NCO% of 7.5%, then add 7 parts of hydrogenated MDI ( 4,4'-dicyclohexylmethane isocyanate content 92%, 2,4'-dicyclohexylmethane isocyanate content 8%) after stirring for 25 minutes, vacuum defoaming to obtain prepolymer A1 with NCO% 9.0%.

[0040] Weigh 2.5g functional filler and expand polymer hollow microspheres 551DE40d42 and add it to the above 100g isocyanate prepolymer A1, then add 30g MOCA and M-CDEA mixed curing agent (the mass ratio of MOCA:M-CDEA is 60:40) , NH 2 : The stoichiometric ratio of NCO is 90%, the mixture is mixed evenly at high speed, and poured into a mold at 80°C, gelled at room temperature for 15 minutes and demoulded, and then secondary vulcanized at 100°C for 16 hours to obtain polyurethane Polishing layer N1.

Embodiment 2

[0042] Isocyanate prepolymer component: Take 37 parts of TDI-100, 54 parts of PolyTHF 1000, 6 parts of DEG, and react at 75°C for 2 hours to obtain an initial prepolymer with NCO% of 8.0%, then add 3 parts of hydrogenated MDI ( 4,4'-dicyclohexylmethane isocyanate content 92%, 2,4'-dicyclohexylmethane isocyanate content 8%) after stirring for 25 minutes, vacuum defoaming to obtain prepolymer A2 with NCO% 9.0%.

[0043] Weigh 1.5g functional filler expanded polymer hollow microsphere 461DET40d25 and add it to the above 100g isocyanate prepolymer A2, then add 30g MOCA and M-CDEA mixed curing agent (the mass ratio of MOCA:M-CDEA is 60:40) , NH 2 : The stoichiometric ratio of NCO is 90%, the mixture is mixed evenly at high speed, and poured into a mold at 80°C, gelled at room temperature for 20 minutes and demoulded, and then secondary vulcanized at 100°C for 16 hours to obtain polyurethane Polishing layer N2.

Embodiment 3

[0045] Isocyanate prepolymer component: Take 34 parts of TDI-100, 54 parts of PolyTHF 1000, 6 parts of DEG, and react at 75°C for 2 hours to obtain an initial prepolymer with NCO% of 7.5%, then add 7 parts of hydrogenated MDI ( 4,4'-dicyclohexylmethane isocyanate content ≥ 99.7%) was stirred for 20 minutes, and vacuum defoamed to obtain prepolymer A3 with an NCO% of 9.0%.

[0046]Weigh 2.5g functional filler and expand polymer hollow microspheres 551DE40d42 and add it to the above 100g isocyanate prepolymer A2, then add 31g MOCA and M-CDEA mixed curing agent (the mass ratio of MOCA:M-CDEA is 50:50) , NH 2 : The stoichiometric ratio of NCO is 90%, the mixture is mixed evenly at high speed, and poured into a mold at 80°C, gelled at room temperature for 20 minutes and demoulded, and then secondary vulcanized at 100°C for 16 hours to obtain polyurethane Polishing layer N3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com