A kind of preparation method of vacuum centrifugal tial intermetallic compound plate

An intermetallic compound and vacuum centrifugation technology, applied in the field of metal material processing and sheet manufacturing, can solve the problems of poor high temperature deformation ability, difficult processing technology, low room temperature plasticity of TiAl alloy, etc. The effect of less equal defects and fewer shrinkage porosity defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

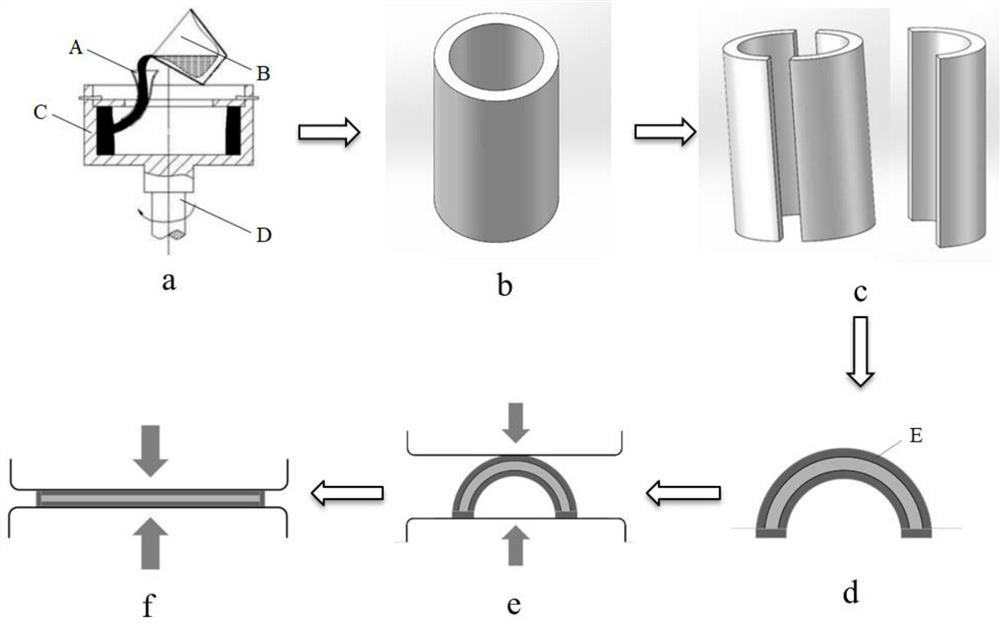

[0039] Such as figure 1 As shown, the present embodiment provides a method for preparing a vacuum centrifuged TiAl intermetallic compound plate, comprising the following steps:

[0040] S1. Melting: Melting pure Ti, pure Al and other alloys in a vacuum environment or under the protection of argon to prepare a TiAl alloy melt. Alloy smelting under vacuum or argon protection can effectively reduce the oxidation and loss of alloy elements and avoid waste.

[0041] S2. Vacuum centrifugal casting: the TiAl alloy melt obtained in step S1 is poured into the casting mold of the centrifugal casting equipment under the condition of vacuum environment and argon protection, and the TiAl alloy melt is constrained to form under the action of centrifugal force, after After rapid cooling, solidification and demoulding, a hollow TiAl alloy cast tube billet is obtained. Using the vacuum centrifugal casting process, under the action of centrifugal force, the alloy melt can be fed during the fi...

Embodiment 1

[0059] This embodiment provides a method for preparing the aforementioned vacuum centrifuged TiAl intermetallic compound plate, comprising the following steps:

[0060] S1. Smelting: Sponge titanium with a purity of ≥99.95%, Al with a purity of ≥99.99%, Al-50Nb (mass fraction, wt.%) alloy and Al-56Mo (mass fraction, wt.%) alloy, according to the composition ratio , smelted into a TiAl alloy melt of Ti-43Al-4Nb-1.5Mo (atomic fraction, at.%) in a vacuum environment. Among them, the vacuum pressure is 10 -3 Pa, to ensure the purity of the alloy melt.

[0061] In this embodiment, a graphite crucible is selected for alloy smelting to prevent Ti and Al elements from chemically reacting with the crucible to introduce impurities. The pouring temperature of the alloy melt is 1580°C, which ensures the fluidity of the alloy melt and at the same time ensures the forming of the tube blank during the mold pouring process.

[0062] S2. Vacuum centrifugal casting: pour the TiAl alloy melt ...

Embodiment 2

[0072] This embodiment provides another method for preparing the aforementioned vacuum centrifuged TiAl intermetallic compound plate, which includes the following steps:

[0073] S1. Smelting: Sponge titanium with a purity of 99.95%, Al ingot with a purity of 99.99%, Al-50Nb (mass fraction, wt.%) alloy, Al-56Mo (mass fraction, wt.%) alloy, high-purity V The ingot and high-purity B powder are smelted into a TiAl alloy of Ti-44Al-5Nb-1Mo-2V-0.2B (atomic fraction, at.%) in an argon-protected environment according to the composition ratio.

[0074] In this embodiment, a graphite crucible is selected for alloy smelting to prevent Ti and Al elements from chemically reacting with the crucible to introduce impurities. The pouring temperature of the alloy melt is 1600°C, which ensures the fluidity of the alloy melt and at the same time ensures the forming of the tube blank during the mold pouring process.

[0075] S2. Vacuum centrifugal casting: the TiAl alloy melt obtained in step S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com