A 780 MPa class high heat input welding steel for improving the toughness of the heat-affected zone and its manufacturing method

A technology of large heat input welding and heat affected zone, applied in the field of high-strength steel welding, can solve the problems of deterioration of HAZ toughness of high-strength steel, increase of MA component distribution, increase of stress concentration points, etc., so as to promote the reduction of quantity and reduce the cost of raw material input. , the effect of reducing the number distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

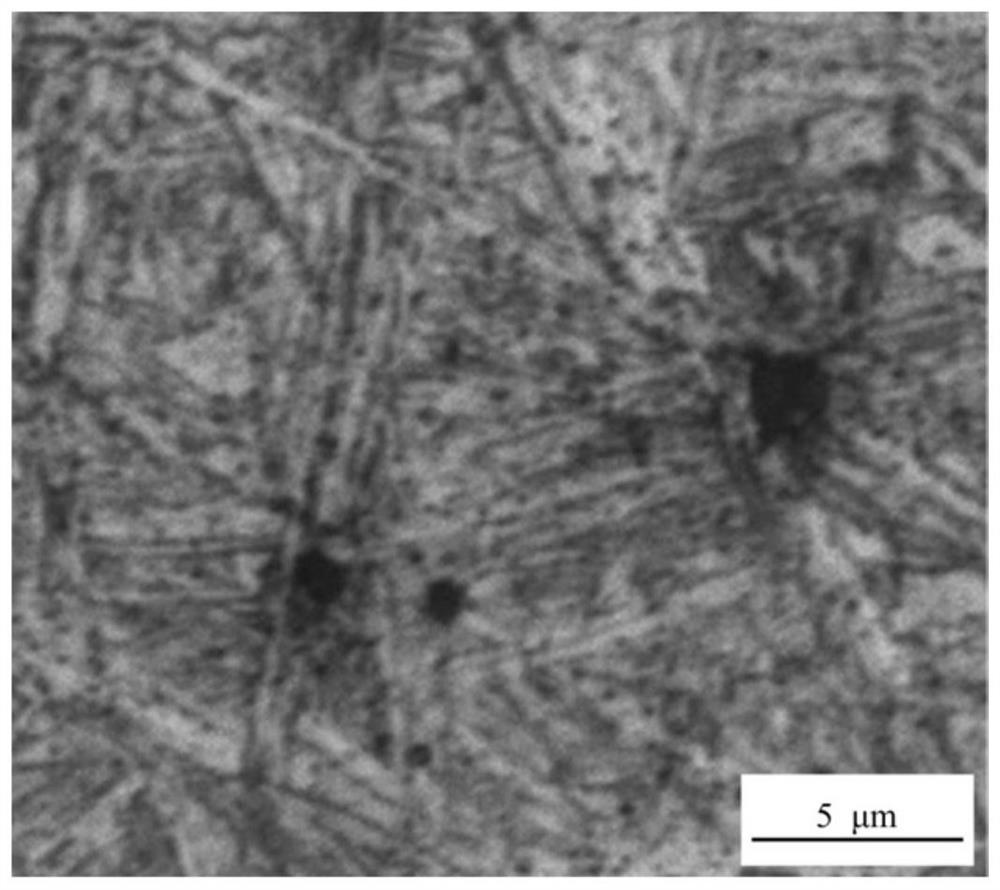

Image

Examples

Embodiment 1

[0018] A 780 MPa grade high heat input welding steel plate, its components and mass fractions are: C: 0.03%, Si: 0.45%, Mn: 1.46%, P: 0.05%, S: 0.017%, Mo: 0.73% , Ni: 2.80%, Ti: 0.11, the balance is Fe and unavoidable impurities.

[0019] The manufacturing method of the above-mentioned 780 Mpa high heat input welding steel for improving the toughness of the heat-affected zone is as follows:

[0020] (1) Smelting: According to the composition design of 780 MPa-level high-heat input welding steel, the required alloy raw materials are smelted at 1650°C, molten steel is smelted, and steel ingots are obtained by pouring at 1600°C;

[0021] (2) Rolling: Heat the steel ingot to 1200°C and keep it warm for 2 hours. After fully austenitizing, the steel ingot is subjected to rough rolling for 3 passes. The pass reduction rate is 10%, the cumulative reduction rate is 30%, and the rough-rolled plate is obtained; the rough-rolled plate is subjected to 3 passes of finish rolling, the fini...

Embodiment 2

[0025] A 780 MPa class high heat input welding steel plate, its components and mass fractions are: C: 0.03%, Si: 0.7%, Mn: 1.1%, P: 0.04%, S: 0.015%, Mo: 0.9% , Ni: 2.20%, Ti: 0.17, the balance is Fe and unavoidable impurities.

[0026] The manufacturing method of the above-mentioned 780 Mpa high heat input welding steel for improving the toughness of the heat-affected zone is as follows:

[0027] (1) Smelting: According to the composition design of 780 MPa-level high-heat input welding steel, the required alloy raw materials are smelted at 1600°C, molten steel is smelted, and steel ingots are obtained by pouring at 1600°C;

[0028] (2) Rolling: Heat the steel ingot to 1200°C and keep it warm for 4 hours. After fully austenitizing, the steel ingot is subjected to rough rolling for 3 passes. The pass reduction rate is 10%, the cumulative reduction rate is 30%, and the rough-rolled plate is obtained; the rough-rolled plate is subjected to 3 passes of finish rolling, the finish ...

Embodiment 3

[0031] A 780 MPa class high heat input welding steel plate, its components and mass fractions are: C: 0.05%, Si: 0.4%, Mn: 2.3%, P: 0.045%, S: 0.013%, Mo: 0.4% , Ni: 3.40%, Ti: 0.08, the balance is Fe and unavoidable impurities.

[0032] The manufacturing method of the above-mentioned 780 Mpa high heat input welding steel for improving the toughness of the heat-affected zone is as follows:

[0033] (1) Smelting: According to the composition design of 780 MPa-level high-heat input welding steel, the required alloy raw materials are smelted at 1650°C, molten steel is smelted, and steel ingots are obtained by pouring at 1600°C;

[0034](2) Rolling: Heat the steel ingot to 1300°C and keep it warm for 2 hours. After fully austenitizing, the steel ingot is subjected to rough rolling for 3 passes. The pass reduction rate is 10%, the cumulative reduction rate is 30%, and the rough-rolled plate is obtained; the rough-rolled plate is subjected to 3 passes of finish rolling, the finish ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com