Method for extracting palladium from low-grade spent alumina carrier catalyst

An alumina carrier, low-grade technology, which is used in the improvement of process efficiency, transportation and packaging, metal processing equipment, etc. Reducing smelting cost, low-cost clean extraction, and remarkable effect of emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

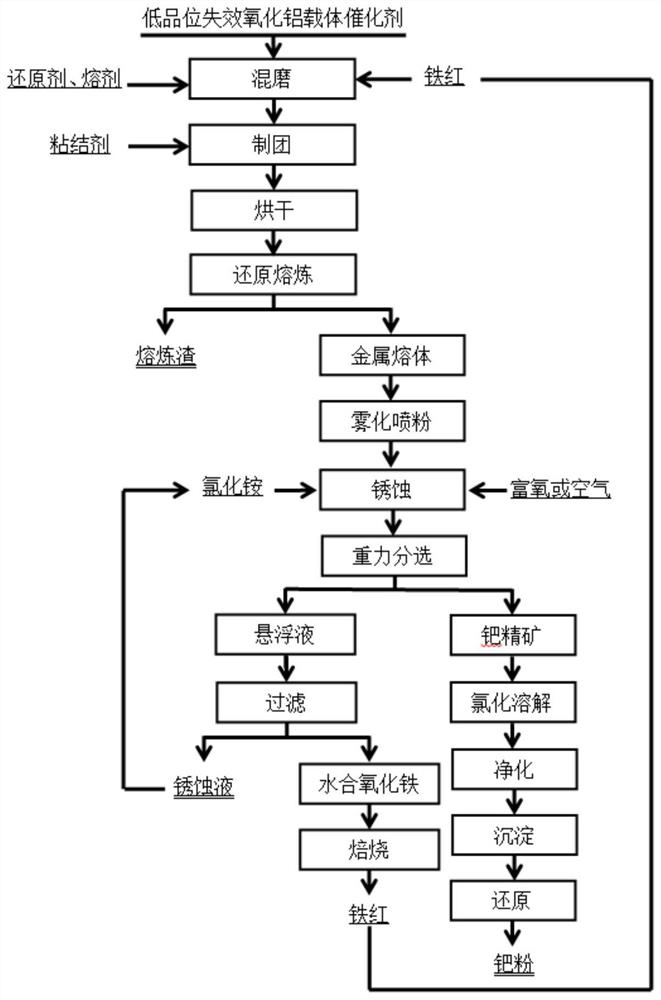

[0034]See accompanying drawing, condition: take by weighing 100kg of low-grade invalid alumina carrier palladium catalyst, add reducing agent, trapping agent, lime, quartz and binding agent and mix, and the addition amount of trapping agent is low-grade invalid alumina carrier palladium catalyst 15% of the weight ratio, the reducing agent ratio is 10% of the weight ratio of the low-grade invalid alumina carrier palladium catalyst, the lime ratio is 1.0 times the weight ratio of the low-grade invalid alumina carrier palladium catalyst, and the quartz ratio is the low-grade invalid 2.0 times the weight ratio of the palladium catalyst supported on alumina, using a spherical egg forming machine to control the diameter of the pellets to 20mm, and the drying temperature is 250°C; the dried pellets are placed in a smelting furnace and smelted at 1350°C for 60min to obtain Smelting slag and metal melt; use atomized powder spraying to treat the metal melt to obtain palladium-containing ...

Embodiment 2

[0036] See accompanying drawing, condition: take by weighing 100kg of low-grade invalid alumina carrier palladium catalyst, add reducing agent, trapping agent, lime, quartz and binding agent and mix, and the addition amount of trapping agent is low-grade invalid alumina carrier palladium catalyst 15% of the weight ratio, the reducing agent ratio is 10% of the weight ratio of the low-grade invalid alumina carrier palladium catalyst, the lime ratio is 1.0 times the weight ratio of the low-grade invalid alumina carrier palladium catalyst, and the quartz ratio is the low-grade invalid 2.0 times the weight ratio of the palladium catalyst supported on alumina, using a spherical egg forming machine to control the diameter of the pellets to 20mm, and the drying temperature is 250°C; the dried pellets are placed in a smelting furnace and smelted at 1350°C for 60min to obtain Smelting slag and metal melt; use atomized powder spraying to treat the metal melt to obtain palladium-containing...

Embodiment 3

[0038] See accompanying drawing, condition: take by weighing 100kg of low-grade invalid alumina carrier palladium catalyst, add reducing agent, trapping agent, lime, quartz and binding agent and mix, and the addition amount of trapping agent is low-grade invalid alumina carrier palladium catalyst 20% of the weight ratio, the reducing agent proportion is 15% of the weight ratio of the low-grade invalid alumina-supported palladium catalyst, the lime proportion is 1.1 times the weight ratio of the low-grade failed alumina-supported palladium catalyst, and the proportion of the quartz is low-grade failure 2.5 times the weight ratio of alumina-supported palladium catalyst, ball egg forming machine is used to control the pellet diameter to 20mm, and the drying temperature is 200°C; the dried pellets are placed in a smelting furnace and smelted at 1400°C for 60min to obtain Smelting slag and metal melt; use atomized powder spraying to treat the metal melt to obtain palladium-containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com