A preparation method and a device for a high-performance silicon-carbon-based negative electrode material

A technology of negative electrode material and carbon-based material, applied in battery electrodes, electrical components, circuits, etc., can solve the problem that the C coating cannot achieve the coating effect, affect the construction of the carbon coating on the particle surface, and cannot be effectively coated and other problems, to achieve the effect of shortening the preparation cycle, avoiding breakage and multiple coating processes, and good electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

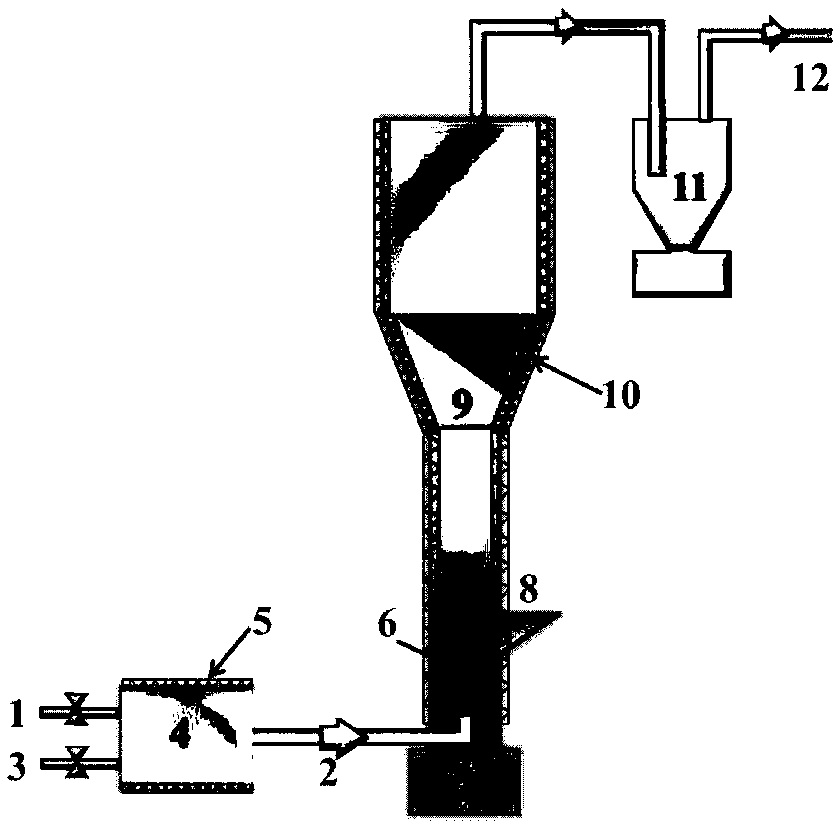

[0061] See attached figure 1 , the present invention is a device for preparing high-performance silicon-carbon-based negative electrode materials, the device is a fluidized bed vapor deposition furnace, and the fluidized bed vapor deposition furnace includes a vapor deposition chamber 9, a sieve baffle 6, a fluidized Gas source 2 , heating buffer tank 4 , vibrating assembly 7 , tailings recoverer 11 and gas collection assembly 12 .

[0062] The fluidized gas source 2 is input to the vapor deposition chamber 9, and a two-layer mesh baffle 6 is arranged on the channel of the fluidized gas source 2, and the fluidized gas that matches the position of the mesh baffle 6 The channel of the source 2 is provided with a material port 8, the inner wall of the vapor deposition chamber 9 is provided with a first heating assembly 10, the sieve baffle 6 can effectively support the precursor, and the fluidization gas source 2 passes through the micropores to make The precursor is in a fluidi...

Embodiment 2

[0067] The invention relates to a device for preparing a high-performance silicon-carbon-based negative electrode material. The device is a fluidized bed vapor deposition furnace, and the fluidized bed vapor deposition furnace includes a vapor deposition chamber, a mesh baffle and a fluidized gas source.

[0068] The fluidized gas source is input into the vapor deposition chamber, and a three-layer sieve baffle is provided on the channel of the fluidized gas source, and a three-layer sieve baffle is arranged on the channel of the fluidized gas source that matches the position of the sieve baffle. The material port, the inner wall of the vapor deposition chamber is provided with a first heating assembly. The sieve baffle can effectively support the precursor, and the fluidized gas source passes through the micropores to make the precursor fluidized and suspended in the vapor deposition chamber for coating.

Embodiment 3

[0070] The present invention is a device for preparing high-performance silicon-carbon-based negative electrode materials. The device is a fluidized bed vapor deposition furnace, and the fluidized bed vapor deposition furnace includes a vapor deposition chamber, a sieve baffle, a fluidizing gas source and Heat the buffer tank.

[0071] The fluidized gas source is input to the vapor deposition chamber, four layers of sieve baffles are arranged on the channel of the fluidized gas source, and a four-layer sieve baffle is arranged on the channel of the fluidized gas source matching the position of the sieve baffle. There is a material port, and the inner wall of the vapor deposition chamber is provided with a first heating assembly. The sieve baffle can effectively support the precursor, and the fluidized gas source passes through the micropores to make the precursor fluidized and suspended in the vapor deposition chamber for coating.

[0072] The buffer heating tank is arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com