Fluorine-based polymer high-frequency substrate, covering film, bonding sheet, and preparation method thereof

A technology of fluorine-based polymers and covering films, which is applied in chemical instruments and methods, circuit substrate materials, adhesives, etc., and can solve problems such as reduced reliability, open circuit, and low surface energy of fluorine-based resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

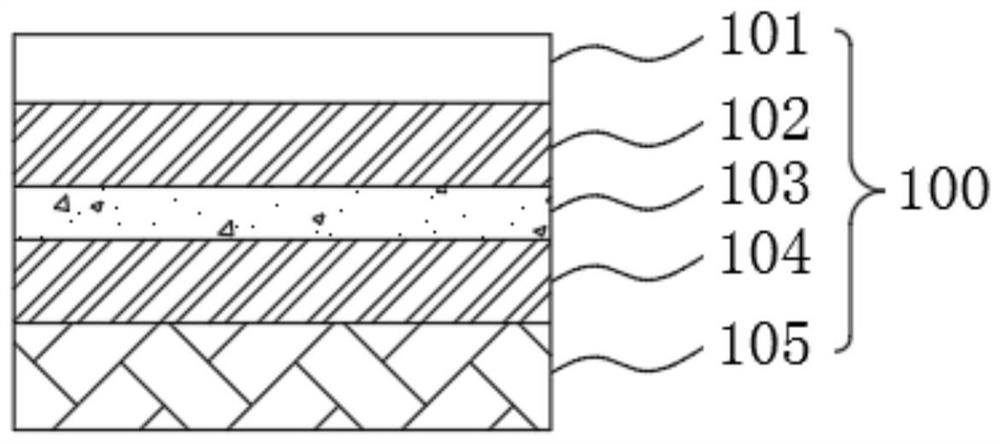

[0106] Embodiment: a kind of fluoropolymer high-frequency substrate, described fluoropolymer high-frequency substrate is a single-sided copper-clad substrate;

[0107] The first structure 100 of the single-sided copper-clad substrate is as follows from top to bottom: copper foil layer 101, first low-dielectric adhesive layer 102, fluorine-based polymer layer 103, second low-dielectric adhesive layer 104 and A polyimide layer 105; the total thickness of the first structure 100 of the single-sided copper-clad substrate is 41-385 μm;

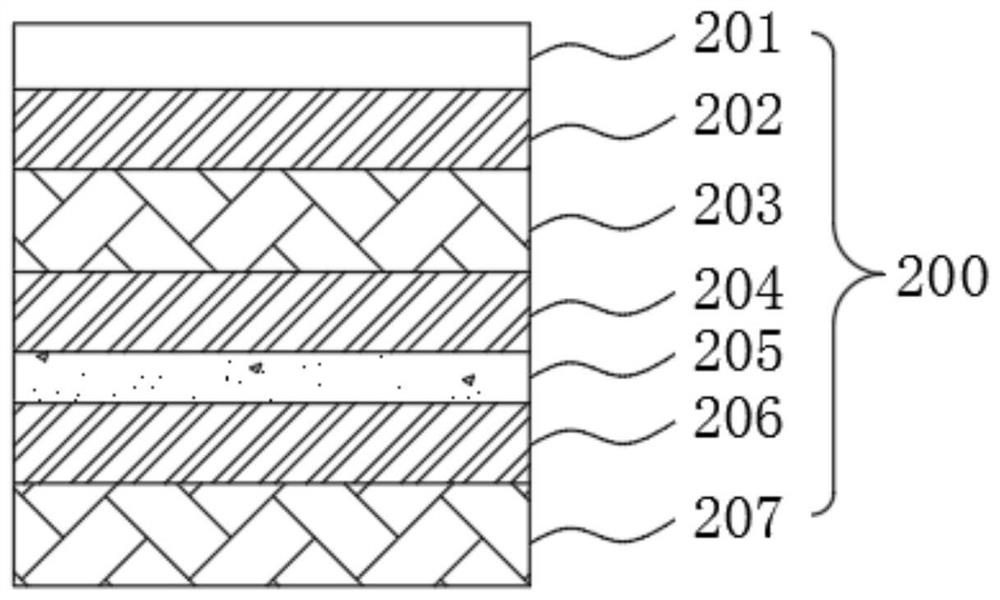

[0108] The second structure 200 of the single-sided copper clad substrate is as follows from top to bottom: copper foil layer 201, first low dielectric adhesive layer 202, first polyimide layer 203, second low dielectric adhesive layer 204, a fluorine-based polymer layer 205, a third low-dielectric adhesive layer 206, and a second polyimide layer 207; the total thickness of the second structure 200 of the single-sided copper-clad substrate is 51-48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com