Sepiolite aerated concrete block and preparation process thereof

A technology of air-entrained concrete and sepiolite, applied in the field of concrete blocks, can solve the problems of insufficient strength and durability, and achieve the effects of excellent adsorption performance, increased pore volume, and small innovation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

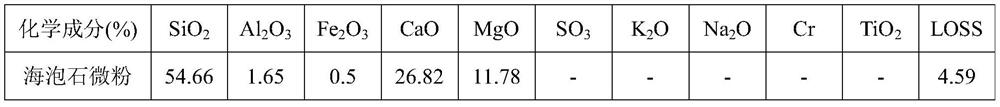

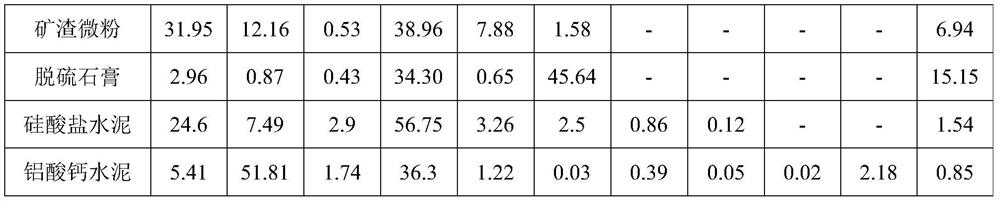

Embodiment 1

[0059] a. The cementitious materials and additives are selected according to the weight percentage of raw materials, including 15% sepiolite, 30% slag, 20% cement (the mass ratio of Portland cement to calcium aluminate cement is 9:1), and fly ash 10% %, kaolin 10%, aluminum powder paste 0.04%, foam stabilizer 0.05%, triethanolamine 0.06%, sodium hydroxide 0.9%, lime 6%, desulfurized gypsum 5%, sodium sulfate 2%, water glass 1% (water glass Modulus 1.2), water reducer 1%, and the rest of the water; the ratio of water to material in the raw material is 0.45.

[0060] b. Mix the gelling materials and stir them at a speed of 140 ± 5 r / min for rotation and 62 ± 5 r / min for revolution, and perform dry mixing for 2 minutes to make a mixture;

[0061] c. Take water accounting for 5% of the total water weight, add aluminum powder paste, foam stabilizer and triethanolamine into water at 55°C, stir for 30s to make a suspension;

[0062] d. Dissolve water glass and sodium hydroxide into ...

Embodiment 2

[0069] The difference between this embodiment and Example 1 is that the weight percentages of raw materials are respectively 25% of sepiolite, 20% of slag, 20% of cement (the mass ratio of Portland cement to calcium aluminate cement is 9:1), pulverized coal Ash 10%, kaolin 10%, water glass 1% (water glass modulus 1.2,), lime 6%, desulfurization gypsum 5%, sodium sulfate 2%, aluminum powder paste 0.05%, foam stabilizer 0.05%, triethanolamine 0.06 %, sodium hydroxide 0.9% (aluminum powder paste, foam stabilizer, triethanolamine, the amount of sodium hydroxide is the percentage of the total amount after the material is mixed with water), water reducer 1%, and the rest of the water; raw materials The water-to-material ratio is 0.5.

[0070] The green body after demoulding is subjected to heat and humidity curing in a 60°C curing box for 28 days to obtain a finished block.

[0071] After testing, the finished blocks have a compressive strength of 5.4MPa and a dry density of 700kg / ...

Embodiment 3

[0073] The difference between this embodiment and embodiment 1 is that the weight percentage is calculated as 0.08% of the raw material aluminum powder paste,

[0074] The green body after demoulding is subjected to heat and humidity curing in a 60°C curing box for 28 days to obtain a finished block.

[0075] After testing, the finished block has a compressive strength of 4.42MPa and a dry density of 687kg / m 3 .

[0076] The results of Examples 1, 2 and 3 of the present invention prove that the present invention recycles the sepiolite micropowder, and then prepares concrete blocks by an autoclave-free method, which is easier to operate than the traditional autoclaved aerated concrete production method , lower cost, the autoclaved-free sepiolite aerated concrete block obtained by it has a porosity of more than 65% and high compressive strength, which is superior to the concrete block produced by the existing autoclaved-free process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com