Soil improvement material component for improving vegetable biomass

A soil improvement and biomass technology, applied in microbial treatment, biological organic part treatment, organic fertilizer and other directions, can solve the problems of aggravating urban haze, land resource pollution, soil fertility failure, etc., to increase vegetable biomass and promote fermentation. process, the effect of improving the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

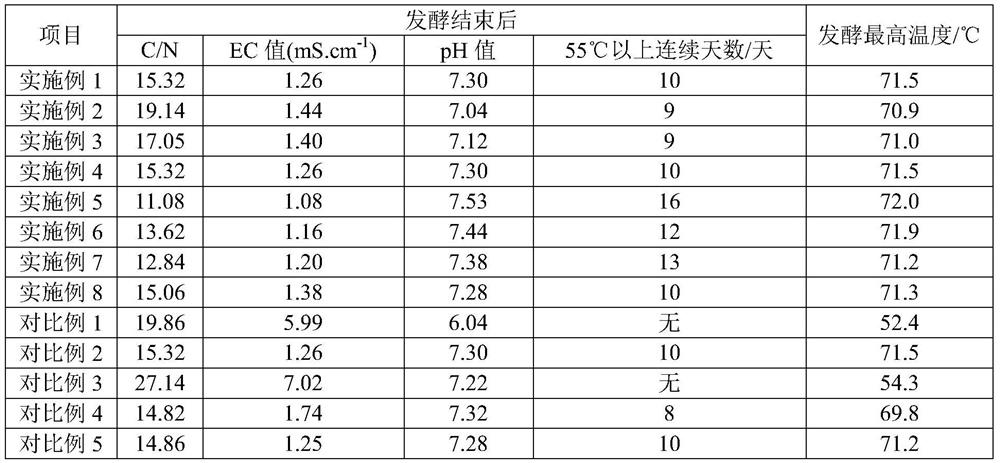

Examples

Embodiment 1

[0028] A soil improvement material component for increasing vegetable biomass, made of biochar and compost;

[0029] Biochar is made from camphor branches in Hangzhou Botanical Garden, which are then calcined and carbonized at low temperature in an anoxic environment. In the carbonization machine, the temperature was raised to 40°C at 1°C / min and kept for 24 hours to make the water migration uniform, and then nitrogen gas was introduced at a flow rate of 5mL / min, and then the temperature was raised to 400°C for low-temperature calcination and carbonization for 12 hours;

[0030] The compost is made by crushing the branches of trees and shrubs to less than 2cm by a pulverizer as compost and urea. In a cement tank that is sealed on all sides, with an opening on the top surface and one side elevation, the length of the cement tank is 1.5m, the width is 1.2m, and the height is 1.3m; then add 0.1% of the mass of the fermentation base material. Microbial agent, and control the humi...

Embodiment 2

[0033] A soil improvement material component for increasing vegetable biomass, made of biochar and compost;

[0034] Biochar is made from broken camphor branches in Hangzhou Botanical Garden and then calcined and carbonized in an anoxic environment. The preparation process is as follows:

[0035]Cinnamomum camphora branches are crushed to a length of less than 2cm by a crusher, ventilated and dried to a water content of 60%, placed in a carbonization machine and heated to 60°C at 2°C / min for 12 hours to make the water migration uniform, and then passed into Nitrogen, the flow rate is 3mL / min, and then the temperature is raised to 500°C for low-temperature calcination and carbonization for 5 hours;

[0036] The compost is made from the branches of trees and shrubs as compost and fermented with urea. The preparation process is as follows:

[0037] Mix the pile material and urea according to the ratio of C / N ratio of 20:1 to obtain the fermentation base material, place it in the...

Embodiment 3

[0040] A soil improvement material component for increasing vegetable biomass, made of biochar and compost;

[0041] Biochar is made from broken camphor branches in Hangzhou Botanical Garden and then calcined and carbonized in an anoxic environment. The preparation process is as follows:

[0042] Cinnamomum camphora branches are crushed by a crusher to a length of less than 2cm, ventilated and dried to a water content of 65%, placed in a carbonization machine at 1°C / min and raised to 40°C for 24 hours to make the water migration uniform, and then nitrogen gas is introduced at a flow rate of at 4mL / min, then heat up to 450°C for low-temperature calcination and carbonization for 8 hours;

[0043] The compost is made from the branches of trees and shrubs as compost and fermented with urea. The preparation process is as follows:

[0044] Mix the stockpile and urea according to the ratio of C / N ratio of 30:1 to obtain the fermentation base material, place it in the cement tank, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com