Quasi-carboxymethyl chitosan and new one-step synthesis process

A technology of pseudo-carboxymethyl chitosan and carboxymethyl chitosan is applied in the field of one-step synthesis of pseudo-carboxymethyl chitosan, which can solve the problem of governance, large amount of waste salt organic water, difficulty in collecting raw materials, etc. It can achieve the effect of excellent water absorption rate and water retention rate, good water absorption and water retention performance, and easy separation and purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

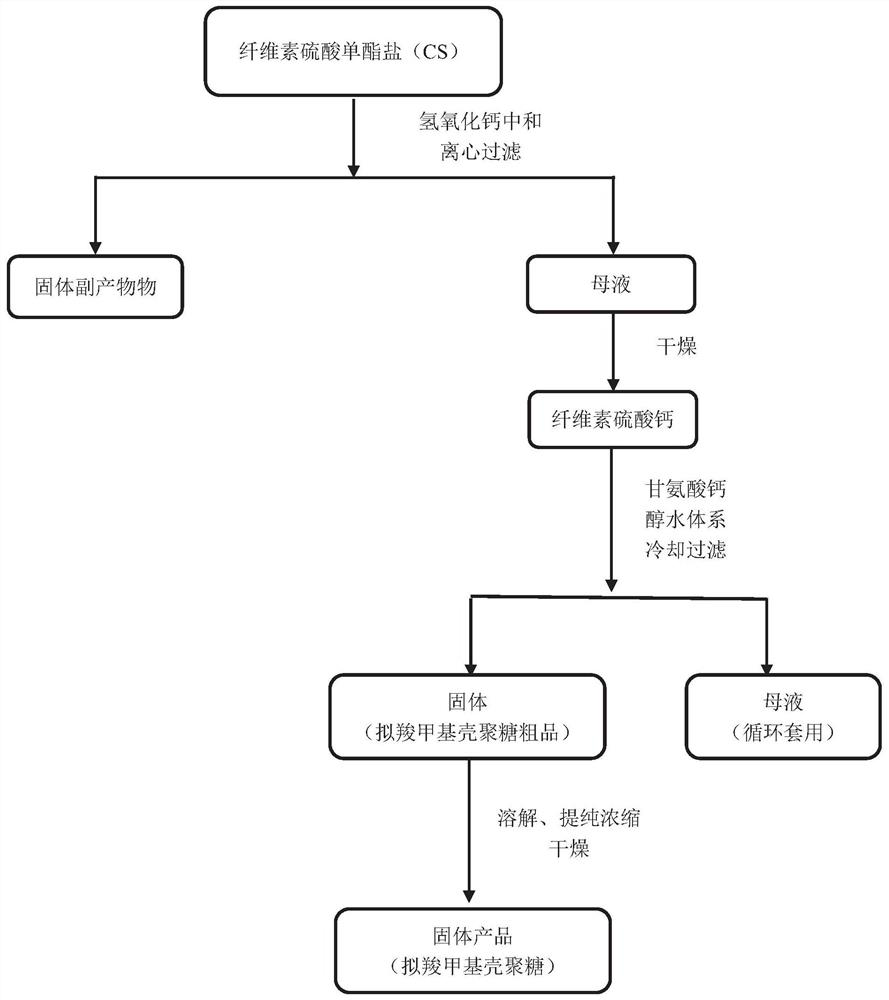

[0055] according to figure 1 The preparation process flow chart of pseudo carboxymethyl chitosan shown in , obtains following conclusion through a large amount of experiments and process exploration: the optimized process condition of pseudo carboxymethyl chitosan preparation is: temperature is below 200 ℃, (preferably 80-160°C), the appropriate reaction time is 6-24h, (preferably 8-16h), and can synthesize carboxymethyl chitosan with a degree of substitution DS=0.6 or so and hemicellulose substituted with carboxymethylamino The mixture of this process degradants and by-products are very few.

[0056] The reaction equation of raw material preparation is as follows:

[0057]

[0058] The reaction equation for preparing pseudo carboxymethyl chitosan is as follows:

[0059]

[0060] See Table 1 for related testing and analysis methods.

[0061] Table 1: Analysis content and analysis method of the product

[0062] analysis content Analytical method Degre...

Embodiment 1

[0063] The preparation of embodiment 1 raw material cellulose sulfate monoester salt

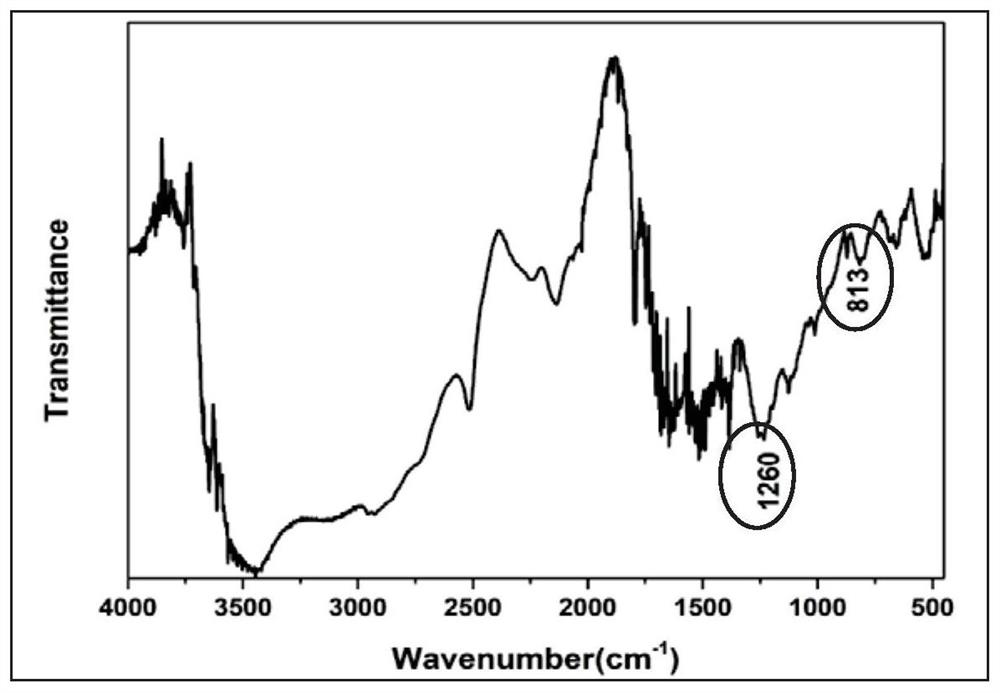

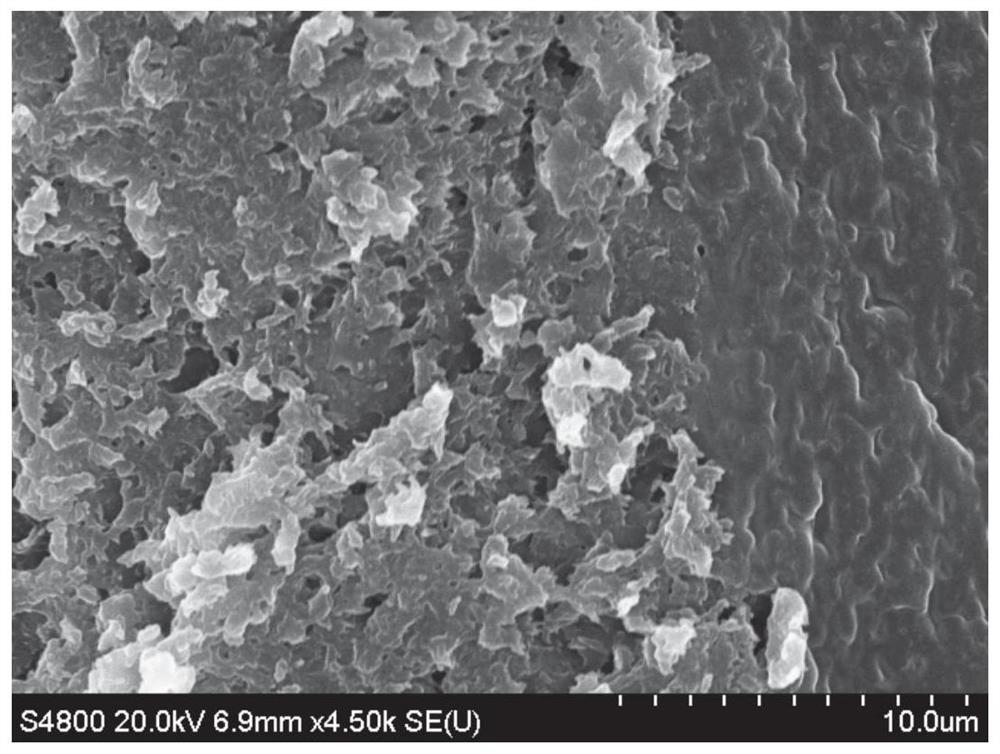

[0064] Weigh 0.486g microcrystalline cellulose, add 3.75ml DCE to swell the cellulose, add 1mol / L SO 3 / DCE sulfonation reagent, by cellulose structural unit and SO 3 The molar ratio is 3: 5 feed intake, after stirring in ice bath for 15min, the reaction solution is placed at room temperature and reacted for 2h to obtain cellulose sulfate monoester (this cellulose sulfate monoester is used in Example 12 and Example 13) , add in 10ml water and lime mixed solution, stirring and neutralizing to pH is 7, filters out solid, and filtrate is calcium cellulose sulfonate, obtains 2.66g of solid product through dialysis, concentrating and drying, and product yield is 54.8%, The test sulfonation substitution degree is 1.2, wherein, the infrared spectrogram of cellulose sulfonate see figure 2 , SEM analysis diagram see image 3 . Carboxymethyl chitosan was prepared using calcium cellulose sulfonate...

Embodiment 2

[0073] Yield and degree of substitution of pseudo carboxymethyl chitosan under different reaction times in the water system of embodiment 2

[0074] Add 0.281g calcium cellulose sulfonate (CaCS) into the autoclave, and add an appropriate amount of calcium glycinate to it, change the equivalent ratio of glucose units in calcium glycinate and calcium cellulose sulfonate to 2:1, add 35ml of Deionized water, the reaction temperature is 180°C, and the reaction time is changed. After the reaction, the solid and liquid are separated. The yield of the liquid after dialysis, concentration and drying is the pure product yield, and the degree of substitution is calculated by elemental analysis.

[0075] Table 2: Degree of substitution and yield of pseudocarboxymethyl chitosan with different reaction times in water system

[0076] Reaction time (h) Degree of Substitution (DSN) Degree of Substitution (DSS) Pure product yield (%) 4 0.09 0.45 44.2 8 0.25 0.30 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com