Production of high-quantum-yield sulfur quantum dots and method for determining ascorbic acid thereof

A technology of ascorbic acid and sulfur quantum, applied in analytical chemistry and nanometer fields, can solve the problems of harsh experimental conditions, unfavorable rapid analysis, complicated and tedious steps, etc., and achieve simple and easy steps, good fluorescence performance and photostability, and good selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method for high quantum yield sulfur quantum dots, comprising the following steps:

[0032] Accurately weigh 0.175 g of sublimed sulfur powder, add 1.2 mL of polyethylene glycol-400, and add 0.8 g of NaOH. After mixing evenly, ultrasonic microwave method at 70 ℃ for 1 h, add 5 mL of 12 wt% H 2 o 2 And continue to microwave for 1 h, centrifuge the obtained product sulfur quantum dots at 7000 rpm for 10 min, take the supernatant and dialyze it with a 100-500 D dialysis bag for 12 h to purify, seal and store to obtain the sulfur quantum dot solution.

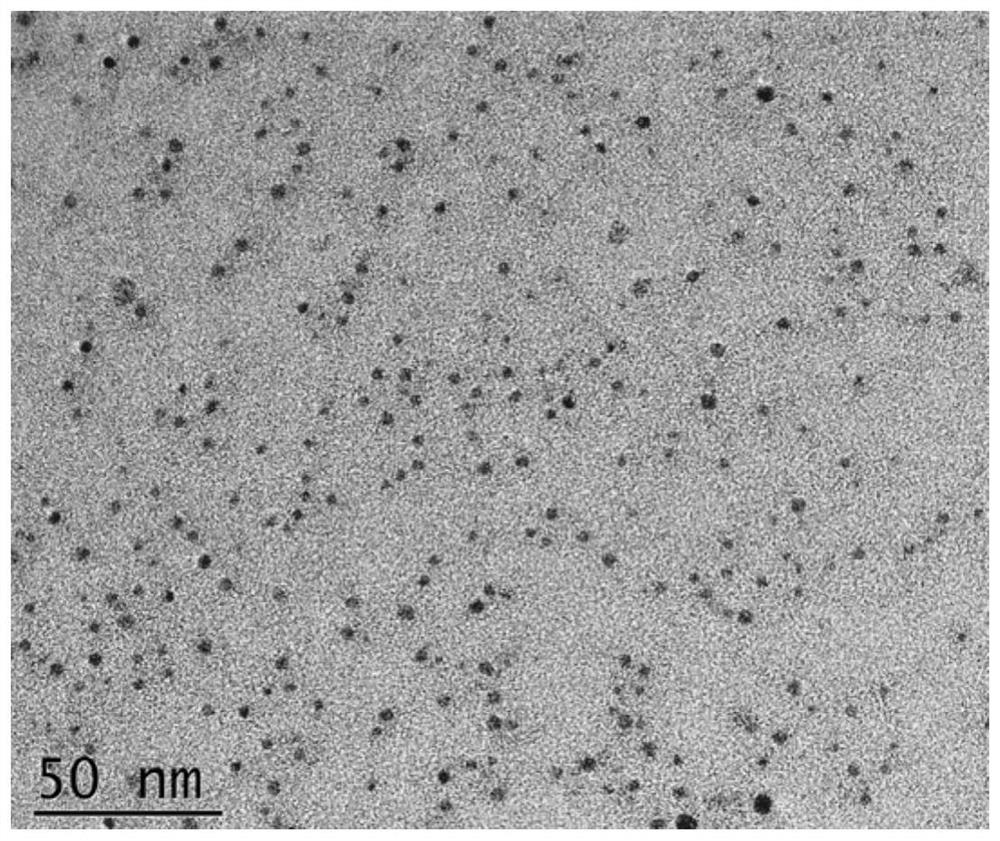

[0033] The morphology of sulfur quantum dots was analyzed by transmission electron microscopy, as shown in figure 1 As shown, it can be seen that the prepared sulfur quantum dots are spherical, the particle size distribution is uniform, and the average diameter is 2.22 ± 0.6 nm.

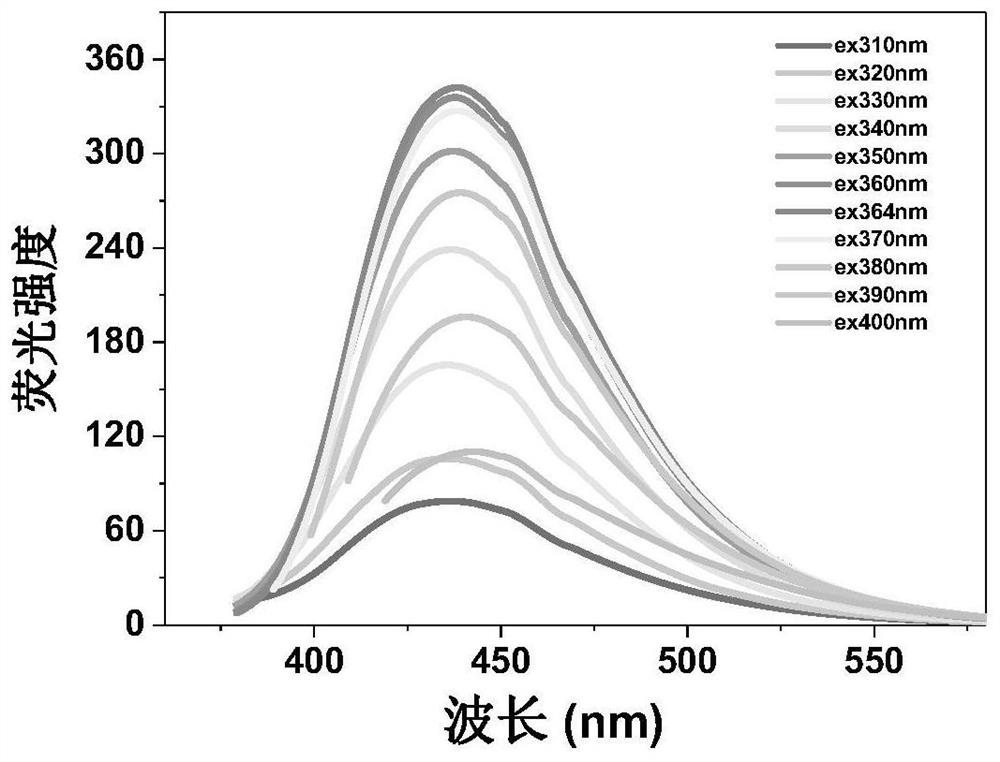

[0034] Such as figure 2 As shown, the sulfur quantum dots prepared by the present invention have a constant maximum emission wav...

Embodiment 2

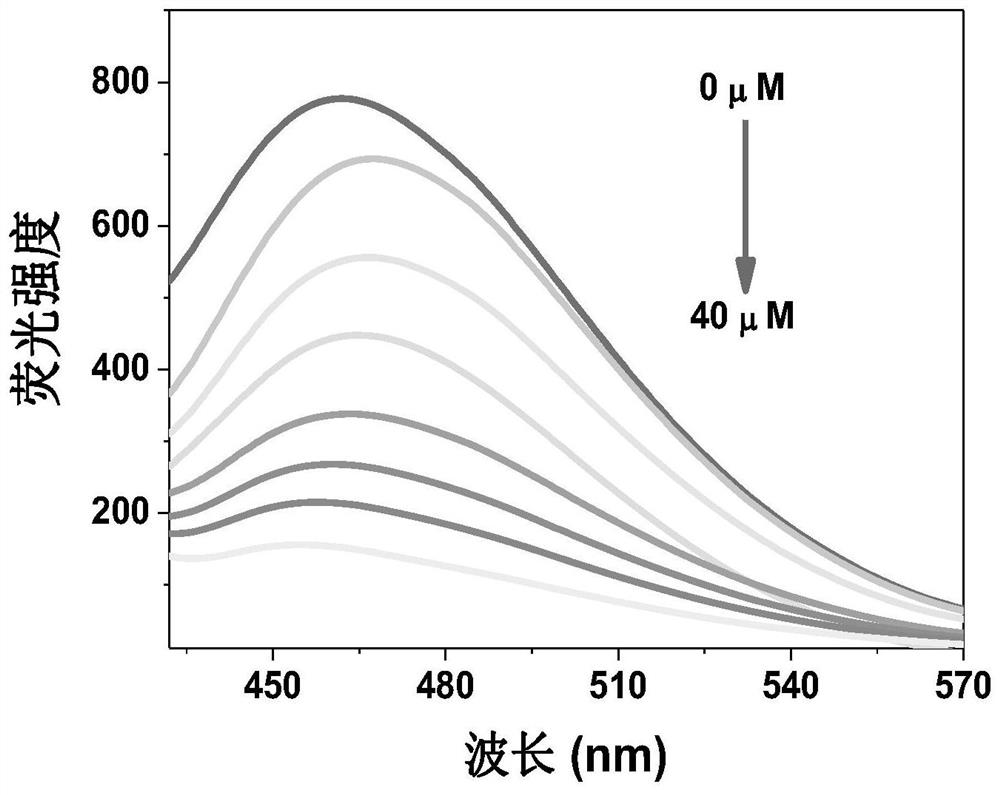

[0036]Selection of Ce(IV) concentration in the composite solution of sulfur quantum dots / Ce(IV) fluorescent probe: Sodium citrate buffer (10 mM, 1325 μL, pH= 3), the sulfur quantum dots prepared in Example 1 (75 μL) and different concentrations of cerium sulfate solutions (50 μL) were successively added to 2 ml EP tubes, reacted at 37 °C for 10 minutes, and measured the fluorescence intensity at 453 nm of the above system. Such as image 3 As shown, after adding different concentrations of Ce(IV) to the solution, the fluorescence of sulfur quantum dots will be quenched sharply, and with the increase of Ce(IV) ion concentration, sulfur in the sodium citrate system at pH=3 The fluorescence of quantum dots is gradually quenched. When the concentration of Ce(IV) reaches 20 μM, the fluorescence quenching of sulfur quantum dots reaches 60%. As the concentration of Ce(IV) continues to increase, the fluorescence of sulfur quantum dots is further quenched. , but the quenching efficien...

Embodiment 3

[0038] Application of the sulfur quantum dot solution obtained in Example 1 in the detection of ascorbic acid.

[0039] The detection method is as follows: sodium citrate buffer (10 mM, 1325 μL, pH=3), the sulfur quantum dots prepared in Example 1 (75 μL), different concentrations of ascorbic acid solution (50 μL) and 0.6 mM The cerium sulfate solution (50 μL) was successively added into 2 ml EP tubes and reacted at 37°C for 10 minutes. Sulfur quantum dot solution and Ce(IV) solution are mixed (buffer: anhydrous citric acid-sodium citrate solution at pH=3) to obtain sulfur quantum dot / Ce(IV) fluorescent probe composite solution, fluorescence quenching, test Fluorescence intensity at the excitation wavelength of 364 nm, and then ascorbic acid solutions with different final concentrations were added to the sulfur quantum dot / Ce(IV) fluorescent probe composite solution at the same time, and the fluorescence intensity of each system at the excitation wavelength of 364 nm was teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com